Knowde Enhanced TDS

Identification & Functionality

- Industrial Additives Functions

- Technologies

Features & Benefits

- Industrial Additives Features

- Features & Benefits

- Acts as a DPF problem solver for applications with rapid rates of soot buildup and minimizes back-pressure.

- Especially attractive for applications with any low temperature cycles in its exhaust profile.

- Initiates passive regeneration (soot oxidation) at low temperatures and more complete regeneration - no need to remove and bake.

- Minimize unscheduled maintenance and operations costs.

- Improves fuel economy and reduces CO: emissions 5 - 12 % (or more depending on engine and application).

- Innovative solution backed by 200 worldwide patents.

- Patented solution increases rate and completeness of fuel combustion.

- Reduces engine out particulate matter by up to 20% with ULSD and 30% with B20/ULSD, so there is less soot to collect in the DPF.

- Better combustion means less soot accumulation on turbocharger and other combustion exhaust components.

Applications & Uses

- Applications

- Typical Applications

On-Road

- Busses

- Sanitation

- Urban delivery

- Tractor trailers

Off-Road

- Construction

- Mining

- Marine

- Military

- Locomotive

Stationary

- Emergency generation

- Distributed power

- Portable gensets

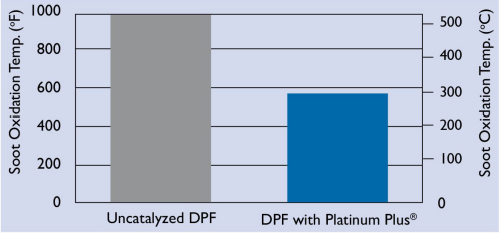

- Passive DPF Regeneration at Low Temperatures

Platinum Plus lowers soot oxidation temperature. Prevents run-away regeneration which can otherwise damage the integrity of the substrate and shorten the life of the DPF.

- Secondary Performance and Maintenance Benefits

- Visibly reduces smoke and opacity.

- Enhances water shedding, lubricity and stability.

- Superior detergents keep injectors clean.

- Less soot buildup in lube oils can result in reduced maintenance and potentially longer drain intervals.

- Sustainability and Bottom Line

- Helps achieve sustainability goals by lowering the carbon impact of diesel applications.

- Reduces CO2 by 5 - 12 % (or more depending on engine and application).

- Furthermore, reduces secondary GHG emissions of PM, HC and NOx.

- Lowers NO2 emissions for bio-diesel applications.

- Improves fuel economy by 5 - 12 % (or more depending on engine and application).

Properties

- Appearance

- Thin Dark Amber Liquid

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity (23 - 24 °C, Typical) | 0.9 | — | — |

| Active Catalyst (1:1500) | 8.0 | ppm | — |

| Flash Point | 77.0 | °C | — |

| Pour Point | 54.0 | °C | — |

Regulatory & Compliance

- Regulatory & Compliance

- VERT-approved with DPF

- MSHA-accepted

- Thoroughly laboratory tested and in field tested.

- Used internationally for over a decade.

Technical Details & Test Data

- Passive DPF Regeneration at Low Temperatures

Packaging & Availability

- Packaging Type

- Packaging & Availability

- Available in 1 liter bottles or 20 and 205 liter drums.

- Platinum Plus® DFX-DPF is available in various formulations depending on application.

- Platinum Plus® DFX-DPF Active is available for use with uncoated DPFs.

Storage & Handling

- Storage & Handling

To maintain peak catalytic activity, Platinum Plus should be stored out of direct sunlight and not exposed for prolonged periods to temperatures in excess of 40°C.