Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Fiber Type

- CAS No.

- 32131-17-2

- EC No.

- 608-706-6

- Technologies

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Advantages

- One of the toughest and most durable man-made polymers

- High tensile and tear strength even at low tabric weights

- Extreme thermal stability and high melting points

- Resistant to most chemicals, solvents, alkalis, and acids

- Excellence in uniformity and high quality applications

- Thermally bonded for a soft and drapable fabric

- Product Highlights

Fabrics are made of nylon (PA66), one of the toughest and most durable man-made polymers, creating products with high tensile and tear strength even at low fabric weights.

The thermal stability of nylon is outstanding. Chemical resistance is outstanding, as these fabrics effectively resist attack from many solvents, alkalis, and acids. Excellent uniformity and work well in applications that demand high quality. In addition, nylon bonds well with adhesive and resin systems, making our fabrics excellent components for laminate and composite systems. These are made with continuous filaments and can utilize various filament geometries, bonding technologies, and polymer additives to achieve the desired performance in your application.- Features

- Superior Uniformity

- Exceptional Strength

- Thermal Stability

- Chemical Compatibility

- Thin Profile

- Natural Flammability Resistance

- Functional Capabilities

- Weight

- Thickness

- Strength

- Elongation / Stretch

- Permeability

- Softness/ Stiffness

- Surface Texture

- Temperature Stability

- Chemical Compatibility

- Custom Colors

- Functional Additives

- Excellent Chemical Properties

Nylon’s chemical make-up, stable resonance structure (the electrons within the polyamide linkage) and strong affinity for hydrogen bonding make it uniquely compatible with a wide range of other chemicals, including:

- Alcohols and Glycols

- Acetate solvents

- Ketones

- Aromatic hydrocarbons

- Hydrocarbon fuels and oils

- Epoxy and Urethane resins

- Organophosphate esters and Phosphates, and

- Alkaline environments

Applications & Uses

- Markets

- Uses

- Automotive

- Apparel

- Home Furnishings

- Medical

- Mold Release

- Design Capabilities

- Polymer & Additives Technology

- Filament Technology

- Bonding Technology

- Web Formation Technology

- Coating Technology

- Nanofiber Substrate Technology

Properties

- Physical Form

- Physico-Chemical Properties

| Value | Units | Test Method / Conditions | |

| Melting Point | 235 - 265 | °C | — |

| Flash Point | 20.0 | °C | ASTM D1929 |

| Auto-Ignition Temperature | 455.0 | °C | ASTM D1929 |

| Decomposition Temperature (at 420°C) | 50.0 | % | — |

| Specific Gravity | min. 1 | — | — |

| Decomposition Temperature (at 900°C) | 96.0 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

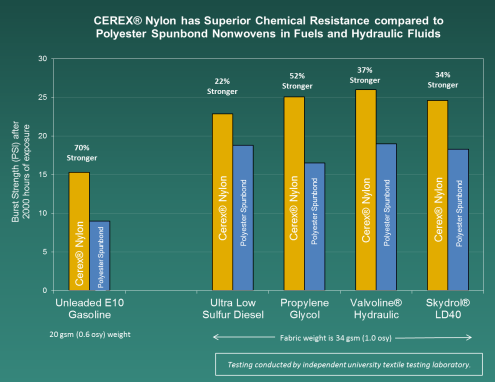

- Hydrocarbon Resistance

Nylon’s amide groups help protect the aliphatic carbonyl chains from solvent attack.

- Alcohols like methanol and ethanol (unleaded gasoline) and Propylene Glycol (hydraulic fluids) attack PET.

- Additives used for flame retardants, lubricity aids, and freeze protection compounds can also attack PET.

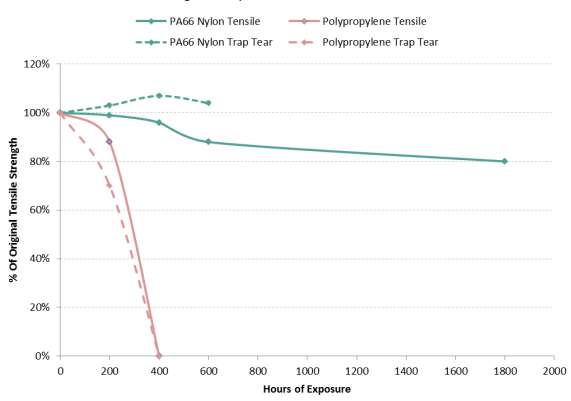

- Long Term Thermal Stability

Thermal degradation must be considered in any automotive design application.

- PA66 shows only 20% loss after 1800 hours of exposure

- PP shows complete loss after only 400 hours of exposure

PA66 Nylon polymer formulations contain no added stabilizers and exhibit natural long term heat stability.

Polypropylene must utilize thermal stabilizer additives designed to interrupt the chain break reaction but are consumed during heat exposure.- Phenol type stabilizers break down suddenly and produce odors

- Hindered amine stabilizers will react more slowly but still suffer the same ultimate fate

Strength Comparison: ISO 2578 at 120°C

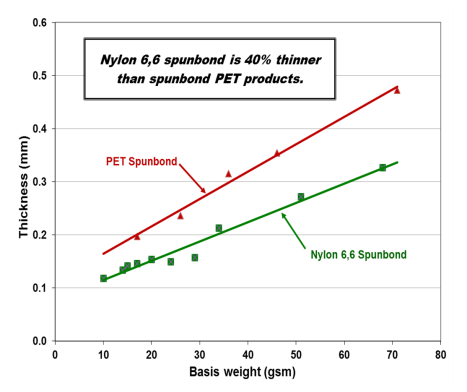

- Thinner Profile Than PET

Allows designs to be

- Smaller,

- More cost effective, and Lighter weight without sacrificing performance or strength.

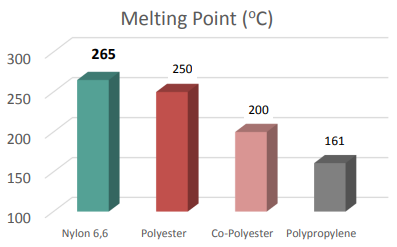

- Excellent Temperature Resistance

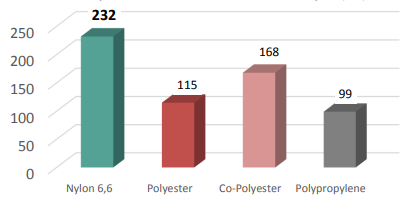

Melting Point (°C)

Nylon 6,6 melts at 265oC which is 24% higher than the Co-PET bonding polymer used in most PET spunbonds..

- It also has a 30% higher heat capacity (1.47 J/g*K) than Polyester.

- Nylon 6,6 absorbs more energy and does not deform as easily as other polymers even at elevated temperatures.

Temperature of Deflection at 66 psi (°C)

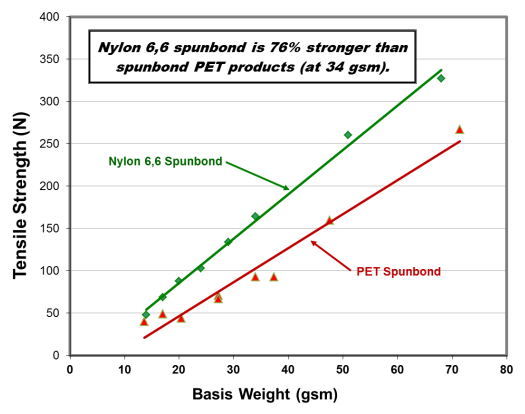

- Greater Tensile Strength Vs. PET

- In fabric form, the strength differential becomes even higher.

- High strength means that you can use a lower weight material in your designs, offering the opportunity to lower weight in the vehicle

- Thin profiles allow designers to integrate these fabrics into composite design for reinforcement allowing removal of other heavier components

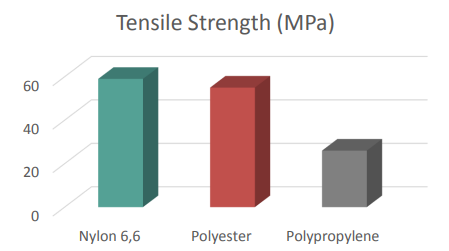

- Superior Strength

As a base plastic, the tensile strength of nylon 6,6 is more than double polypropylene and 7% greater than polyester.

- Co-polyesters that are used in many spunbond products have an even lower tensile strength.

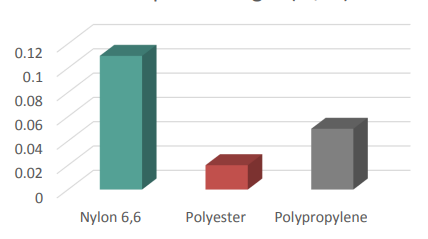

Izod Impact Strength (kJ/m)

- Nylon 6,6’s izod impact strength is more than double polypropylene and more than 5 times greater than polyester.

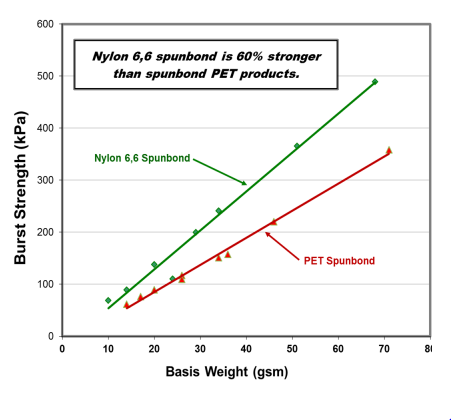

- Superior Burst Strength Vs. PET

- Able to withstand high pressure applications including difficult processing and system pulsations

- Improves durability and service life

- Offers lower basis weight options that can reduce weight, cost and waste.

Packaging & Availability

- Product Range

- PBN-II® fabrics are available in basis weights ranging from 30 ounces per square yard (YD2) or 10 grams per square meter (GSM) to 4.0 ounces per square yard (YD2) or 136 grams per square meter (GSM).

- Finished widths are available up to 120 inches (approximately 3 meters)

- We offer several packaging options to fit your needs and protect your fabric during transit.