Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Coating Type

- Use Level

- 0.35 - 1.4 wt%

- Application pH Range

- 7 - 11

- Application

- Coatings, Adhesives & Inks: Will improve wet adhesion to many difficult substrates, i.e. glass, ceramics, concrete, wood and plastics (except untreated PP/ PE), etc. and all metals with accompanying improved salt fog resistance, reduction of creep at the scribe, and reduced blistering. In WB exterior primers and deck stains, will eliminate peeling on wood substrate.

- Water-Borne Coatings: For acrylic, styrenated acrylic, PUD and alkyd coatings having pH 7-11. Use level 0.35 - 1.4 wt% on polymer solids*.

- 2K Epoxy and 2K Urethane: Always add to hardener (epoxies) or polyol (urethanes). Use level 0.35 - 1.4 wt% on polymer solids*.

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Active Matter Content | 34 | wt% | — |

| Complexed Organics | 21.3 - 21.9 | — | — |

| Specific Gravity | 1.18 | g/ml | — |

| Total Metal Content | 7.3 - 7.9 | % | — |

| Neutralizing Agent | MEA | — | — |

| Organofunctionality | Amino | — | — |

| pH Value (2% Solution) | 6.5 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Procedure

1. Water-Borne: Post add at 0.35 - 1.4 wt per cent on polymer solids*. Mix with conventional paddle-type mixer. See Bulletin: “Calculating Use Level.”

2. 2K Epoxy and 2K Urethane: Optimum performance is achieved when added to the hardener (epoxies) or polyol (urethanes). Product must be high shear mixed with a Cowles type mixer. Milling alone is not sufficient. Use Level 0.35 - 1.4 wt%t on polymer solids. See Bulletin: “Calculating Use Level."

- Product Performance

Superb Durability on Glass C-515.72HRX

A study was conducted looking at various Chartwell products in WB Acrylic DAP glass sealant. The sealant was applied to bond 2 clean glass microscope slides with a 1 inch overlap.

After 72 hours of drying, the bonded slides were placed in water at ambient temperature. Time to failure (separation) is as follows:

Control < 24 hrs B-515.71W 48 hrs, 0.35% C-515.72HRW 288 hrs @ 0.35%

96 hrs @0/70%B-519.71W (new product) 72 hrs @ 0.35, 0.70% C-515.72HRX >9000 hours* @ 0.35% (*no failure yet!)

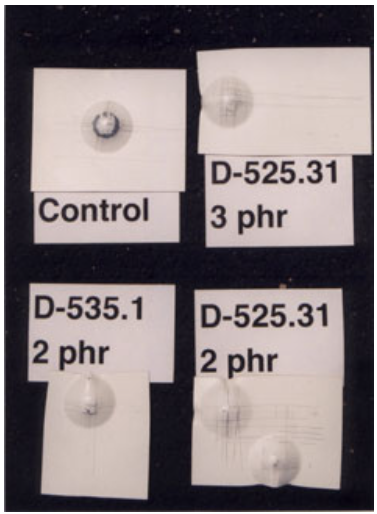

96 hrs @ 0.70, 1.00 %Adhesion of Polyester Baking Enamel on CRS

Conclusions:a

1. Without adhesion promoter (control>50% of coating removed

2. Addition of D-525.31 to the grind stage sharply reduces coating removal as follows:

Control – 50%

2phr – <1%

3phr – 0%Current recommendations: C-515.71HR, C-515.71HRX

3. Excellent humidity and salt-fog resistance