Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Application

(1) Pigment dispersion: Recommended for dispersion of difficult to disperse pigments, ie phthalo blue/ green, carbon black, etc. Also for all inorganic pigments, conductive pigments, and mineral fillers. Particularly useful for the dispersion of these pigments in solvent-borne coatings and polyolefins.

(2) Thermoplastics: Use of D-535.1 to treat mineral fillers, ie calcium carbonate, mica, silica, clay, etc. will result in improved physical properties of the compounded polyolefin.

Properties

- Physical Form

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Active Matter Content | 24 | wt% | — |

| Complexed Organics | 9.9-10.1 | — | — |

| Specific Gravity | 1.12 | g/ml | — |

| Total Metal Content | 4.3 - 4.5 | % | — |

| Organofunctionality | Hydrocarbon | — | — |

| pH Value (2% Solution) | 4 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Procedure

- HIGH SHEAR MIXING NECESSARY IN ALL SOLVENT-BORNE SYSTEMS

(1) Coatings/ Inks: Optimum performance is achieved when added directly to the grind stage resin and high shear mixed for 15 mins before adding other components. Must be high shear mixed with a Cowles type mixer. Milling alone is not sufficient.

(2) Adhesives: 1.0-2.0 phr, post add recommended under agitation.

(3) Plastics: 1.0-2.0 phf (parts per hundred filler); recommend pretreat of pigments/ fillers in a Henschel or similar mixer and subsequently compound with resin. For high surface area pigments/ fillers, i.e. fumed silica, carbon black, phthalo, and similar use 3.0-5.0 phf.

(4) Rubber: 1.0-3.0 phr, add directly onto silica or other filler and compound in a Banbury mixer.

- Product Performance

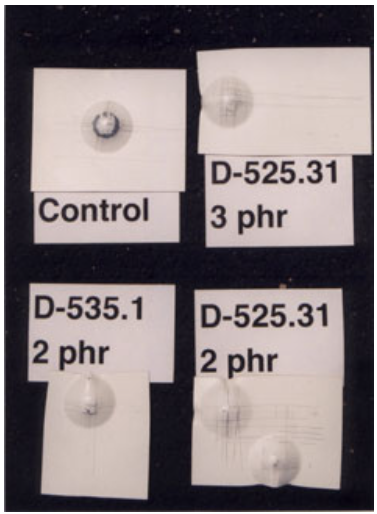

Adhesion of Polyester Baking Enamel on CRS

Conclusions:a

1. Without adhesion promoter (control>50% of coating removed

2. Addition of D-525.31 to the grind stage sharply reduces coating removal as follows:

Control – 50%

2phr – <1%

3phr – 0%Current recommendations: C-515.71HR, C-515.71HRX

3. Excellent humidity and salt-fog resistance