Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features

- High strength.

- Suitable for bonding plastic membranes.

- Low application temperatures (140°C-160°C).

- Excellent heat resistance and solvent resistance.

- Excellent high temperature and low temperature resistance.

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Instructions for Use

For best results, ensure parts are clean, dry and free from oil and grease, although good bonds can still be achieved on ‘as received’ or slightly oily parts. The temperature of substrate should not be lower than 20℃. Low temperature will shorten the open time and cause the bonding failure. If needed, pre-heating of the substrate is recommended. Dispense bead of product onto substrate. Mate opposite substrate within recommended open time. Allow for handling strength to be achieved.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Solid Content | 100.0 | % | — |

| Specific Gravity (25°C) | 1.1 | — | — |

| Viscosity (Brookfield HBTD 10rpm at 120°C) | 12000±3000 | cp | — |

| Viscosity (Brookfield HBTD 10rpm at 140°C) | 8000±2000 | cp | — |

| Open Time (1mm line) | 2021-01-02 | minutes | — |

| Application Temperature | 140-160 | °C | — |

| Coefficient of Thermal Expansion | 169.8 | μm/ (mK) | — |

| Coefficient of Thermal Conductivity | 0.32 | W/ (mK) | — |

| Specific Heat | 2.7 | KJ/ (Kg.K) | — |

| Elongation at break | min. 410 | % | — |

| Tensile Modulus | min. 200 | MPa | — |

| Tensile Strength | min. 8.2 | MPa | — |

| Tensile Shear Strength | min. 6.0 | MPa | — |

Technical Details & Test Data

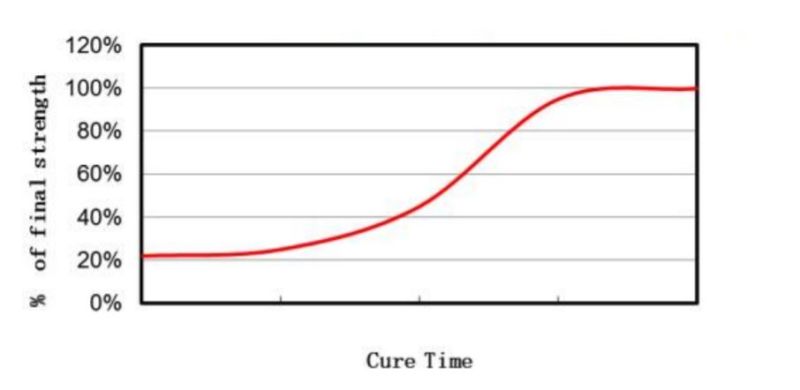

- Cure Speed Curve

The below curve is for reference only. The cure speed is dependent on temperature, humidity and substrate choice. Please contact your local sales representative for assistance and recommendations regarding this product.

Cured Condition: 25°C; 50%-70%RH

Substrates: Fiber sheet & Fiber sheet

Strength: Tensile Shear Strength.

Storage & Handling

- Storage

Optimal storage conditions are between 15℃ to 30℃ and stored in original sealed foil bag. Storage outside this temperature range can adversely affect product properties and may reduce the stated shelf life.