Knowde Enhanced TDS

Identification & Functionality

- Fundamental Parameters

Fundamental Parameters

Test method

Unit

Typical value

Appearance

Visual inspection

White pellet

MI

(190℃,10Kg)

ISO1133

g/10min

5

Density

ISO1183

g/cm3

1.03-1.04

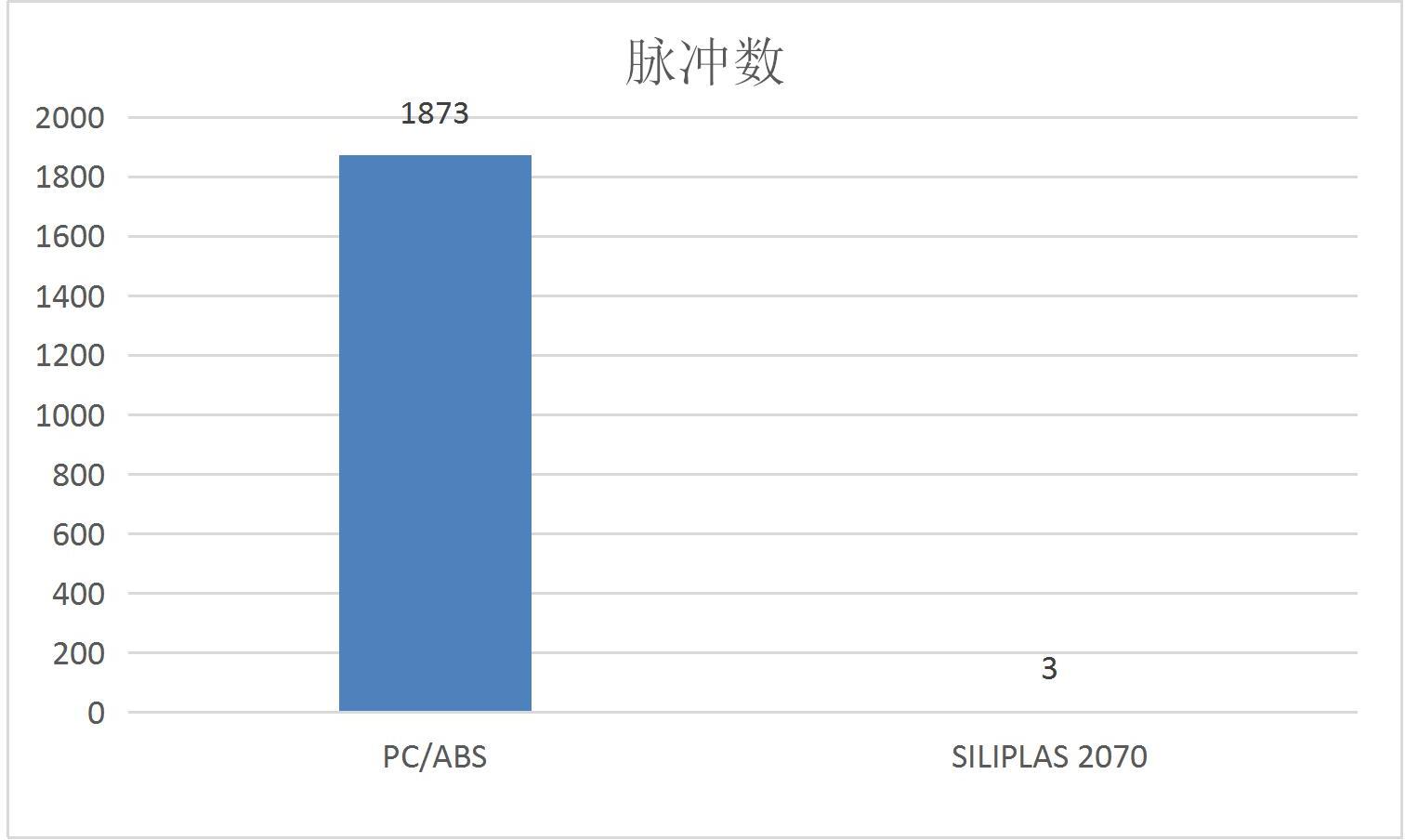

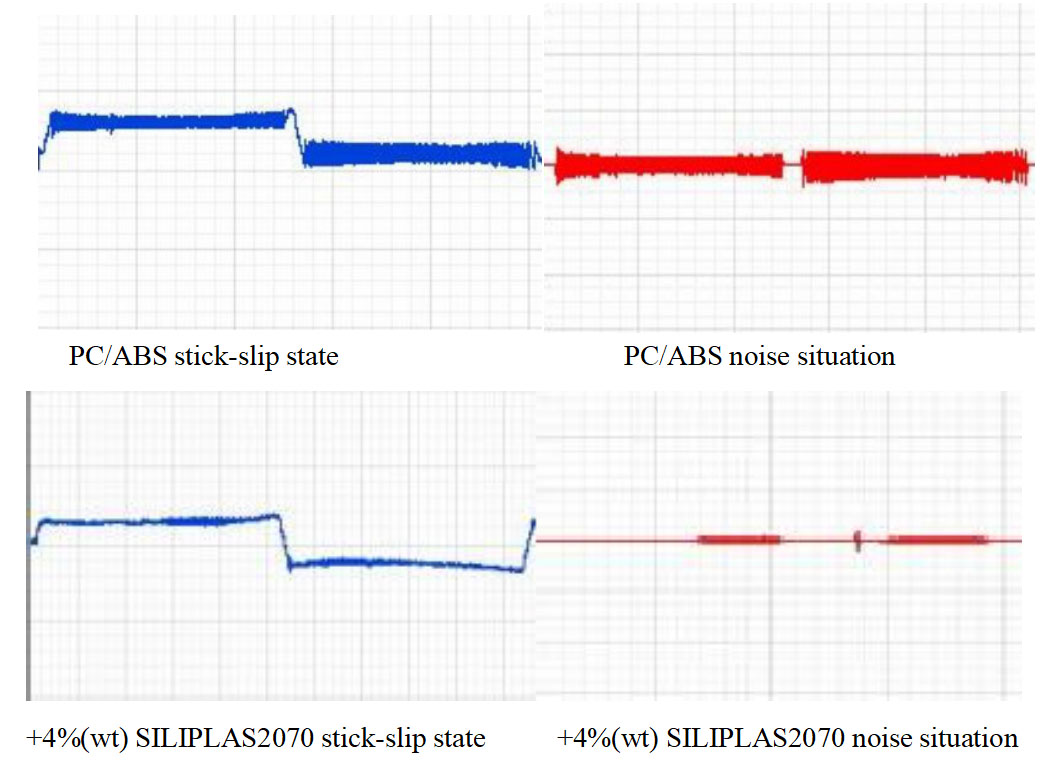

The graph of the pulse value change in the stick-slip test of PC/ABS after adding 4% SILIPLAS2070:

It can be seen that the stick-slip test pulse value of PC/ABS after adding 4% SILIPLAS2070 has dropped significantly, and the test conditions are V=1mm/s, F=10N.

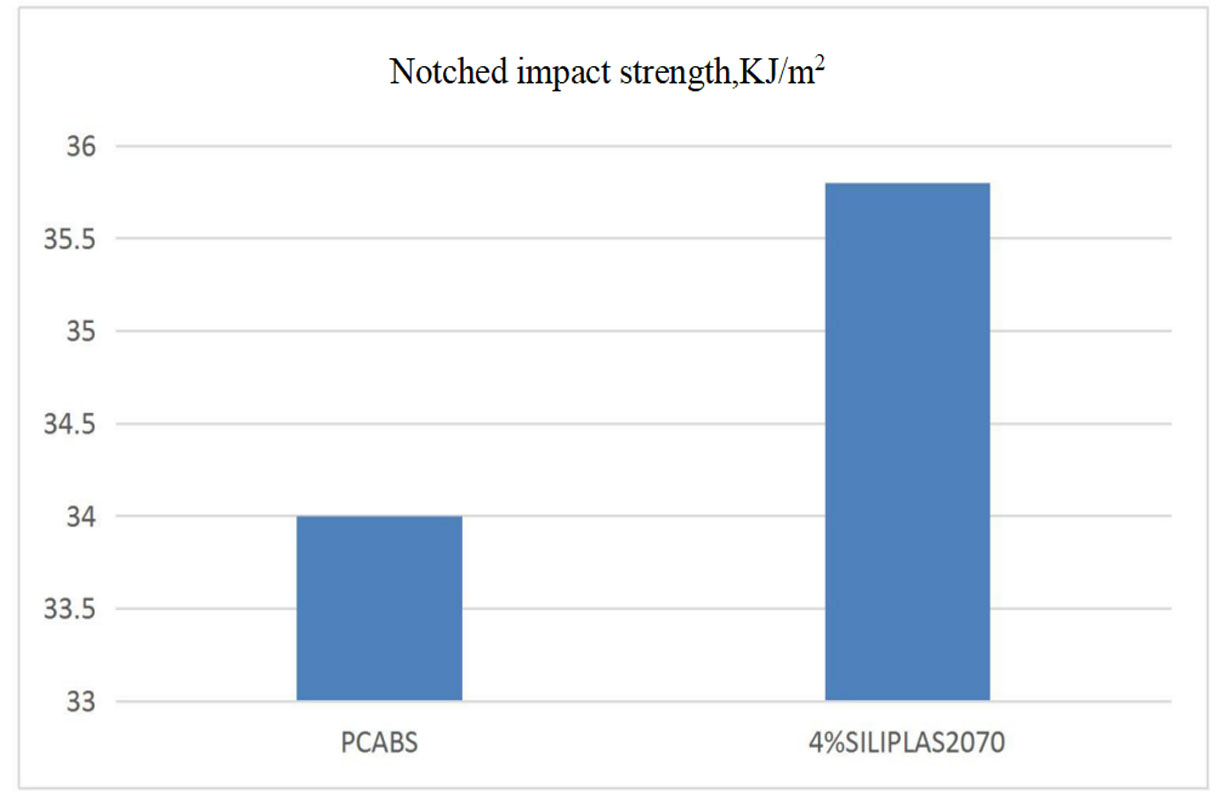

After adding 4% SILIPLAS2070, the impact strength will not be affected.

Features & Benefits

- Features

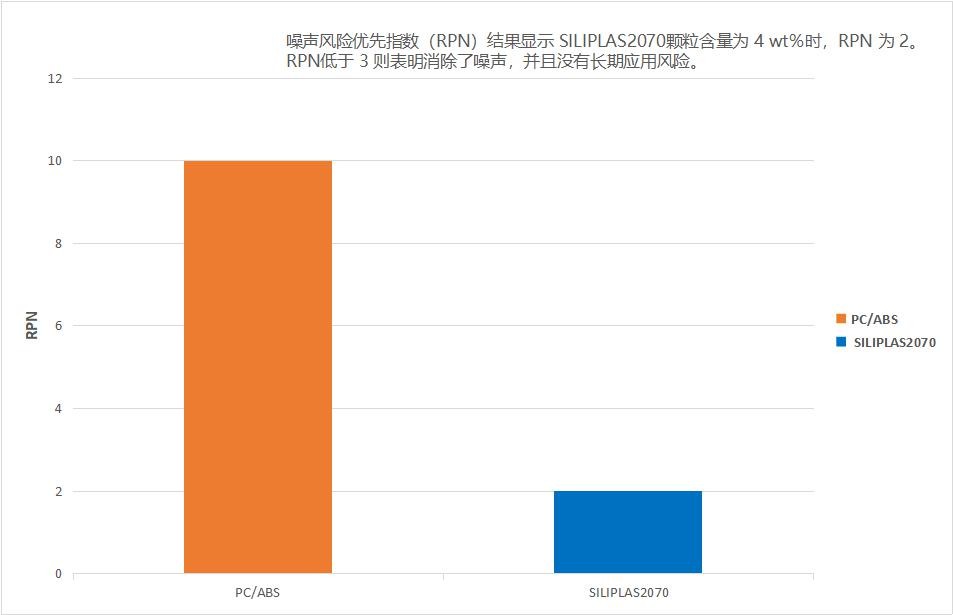

•Excellent noise reduction performance: RPN<3 (according to VDA 230-206)

• Reduce stick-slip

• Instant, long-lasting noise reduction characteristics

• Low coefficient of friction (COF)

• Minimal impact on the key mechanical properties of PC / ABS (impact, modulus, strength, elongation)

• Effective performance with low addition amount (4wt%)

• Easy to handle, free flowing particles

The noise risk priority index (RPN) results show that when the content of SILIPLAS 2070 is 4% (wt),the RPN is 2. RPN below 3 indicates that the noise is eliminated and there is no long-term application risk.

- Benefits

• Minimize disturbing noise and vibration

• Provide stable COF during the service life of parts

• Optimize design freedom by implementing complex geometric shapes

• Simplify production by avoiding secondary operations

• Low dosage, improve cost control

Applications & Uses

- Applications

• Automotive interior parts (trim, dashboard, console)

• Electrical parts (refrigerator tray) and trash can, washing machine, dishwasher)

• Building components (window frames),etc.

- Usage and Dosage

Added when the PC/ABS alloy is made, or after the PC/ABS alloy is made, and then melt-extrusion granulated, or it can be added directly and injection molded (under the premise of ensuring dispersion).

The recommended addition amount is 3-8%, the specific addition amount is obtained according to the experiment

Packaging & Availability

- Packaging Type

- Packaging

25Kg / bag , craft paper bag.

Storage & Handling

- Storage and Shell Life

Transport as non-hazardous chemical. Store in a cool , well ventilated place .

Original characteristics remain intact for 24 months from the production date , if kept in recommend storage.