Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Base Oil Type

- Product Type

- Technologies

- Product Families

- Composition

OPTICOOL 372(E) is compounded with the most effective extreme pressure and anti-weld additives. These additives along the base lubricant provide both hydrodynamic (barrier film) and boundary lubrication, which effectively extend tool life and improve surface finish. A biological preservation package provides microbial control virtually eliminating any adverse effects on the skin. OPTICOOL 372(E) does not contain nitrites, phenols, sulfur, mercurials, formaldehyde or chlorinated additives.

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Properties

- Stable emulsion for long lasting use.

- Unique base oil technology.

- Extreme pressure capability.

- Minimizes rancidity and odors.

- Lowers disposal and downtime costs.

- Corrosion protection

- Virtually eliminates adverse skin effects.

Applications & Uses

- Markets

- Application Area

- Suggested Uses

- Stable emulsion for long lasting use.

- Unique base oil technology.

- Extreme pressure capability.

- Minimizes rancidity and odors.

- Lowers disposal and downtime costs.

- Corrosion protection

- Virtually eliminates adverse skin effects.

- Directions

OPTICOOL 372(E) should be added to water at the recommended starting point. It is important that the coolant be added to water. Do not add water to the coolant. Before adding OPTICOOL 372(E) to any reservoir remove old coolant, fines and residues from the system. Drain the old coolant from the sump, charge the system with Chesterton 218 HDP Cleaner at 5% concentration. Circulate the cleaner for up to 2 hours through all lines, tool holders and work pieces. Dilutions in excess of 40:1 are not recommended since the corrosion protection and resistance to bacterial attack will be reduced.

- Recommended Starting Dilutions

Alloy Steels Steel Aluminum Boring 10% 5% 5% Drilling 10% 5% 5% Milling 10% 5% 5% Reaming 10% 5% 5% Tapping 10% 5% 5% Turning 5% 5% 5% Stamping 10% 10% 10% Drawing 10% 10% 10%

Properties

- Physical Form

- Appearance

- Transparent, Milky

- Soluble in

- Water

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Base Fluid | Mineral Oil | - | - |

| Flash Point | 170.0 | °C | - |

| Freeze Thaw Stability | Pass | - | - |

| pH (10% Concentration) | 9.4 | - | - |

| Residue | non-sticky, re-emulsifiable | - | - |

| Specific Gravity | 0.987 | - | - |

Technical Details & Test Data

- Concentration Check

Storage & Handling

- Coolant Maintenance

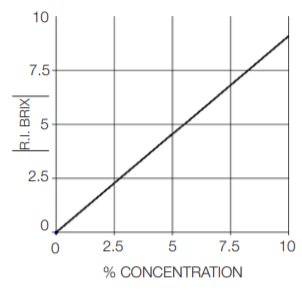

Concentration of the fluid changes constantly during use due to evaporation and “drag out” on chips. Volume loss to evaporation is 100% water. For maximum performance, the concentration should be monitored and maintained on a regular basis. The Brix chart above gives the approximate relationship between coolant concentration and refractometer reading. Often it is helpful to monitor the sump’s pH. If the pH is or drops, below, 8.5 the sump is imbalanced and requires conditioning. Adding fresh coolant or Opticool additives restores the pH level, maximizing coolant performance.

- Clean Up

Residual Coolant on parts, equipment and machine tools is easily removed by rinsing with water.

- Waste Disposal

If permitted by local or state regulation, the product may be discharged into a waste disposal system, but only after the water insoluble fraction is removed with acid-alum or alum-polymeric demulsifiers.