Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 7727-43-7

- EC No.

- 231-784-4

- Technologies

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Features

- High Brightness

- Chemically Inert

- Easily Dispersed

- Highest density of any extender

- Good energy absorption and sound deadening properties

- Excellent Thermal Stability

- 2.5-3.0 Mohs Hardness - Excellent Sanding Properties and Good Scrub Resistance

- Low Oil Absorption

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Polymers & Resins

- Base Chemicals End Uses

- Coating Type

- Plastics & Elastomers End Uses

- Uses

Coatings:

- Automotive Primers

- Automotive Topcoats

- High Gloss Enamel

- Powder Coatings

- Semi-Gloss Latexes

- Gloss Latexes

- Industrial Coatings

- Architectural Coatings

- Maintenance Coatings

- Industrial Primers

Fillers:

- Plastics

- Ceramics

- Friction Materials

- Rubber Goods

- Plastisols

- Adhesives

- Latex products

- Urethane Foams

- Acoustical Compounds

- Insulating Materials

- Sound Attenuation Products

Properties

- Color

- Physical Properties

- Chemical Analysis

| Value | Units | Test Method / Conditions | |

| Apparent Dry Bulk Density (Compacted) | 115 | lbs/ftᶟ | — |

| pH Value | 8.5 | — | — |

| Apparent Dry Bulk Density (Loose) | 75 | lbs/ftᶟ | — |

| Bulking Value | 0.0279 | gal | — |

| Color-L * | 95 | — | CIE Lab |

| Density | 268 | lbs/ftᶟ | — |

| Density | 35.82 | Wt./SolidGallon | — |

| Hegman Fineness | 6 | — | — |

| Median Particle Size | 3 | microns | — |

| Oil Absorption | 11 | — | — |

| Retained on 325 mesh Screen | 0 | wt % | — |

| Specific Gravity | 4.4 | — | — |

| Top Size | 15 | microns | — |

| Value | Units | Test Method / Conditions | |

| Al₂0₃ Content | 0.01 | % | — |

| BaS0₄ Content | 98 | % | — |

| Fe₂O₃ Content | 0.02 | % | — |

| Ignition Loss | 0.75 | % | — |

| Moisture Content | 0.1 | % | — |

| Total Heavy Metals | 0.05 | % | — |

| Total Silicates Content | 0.82 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Quality Standards

Technical Details & Test Data

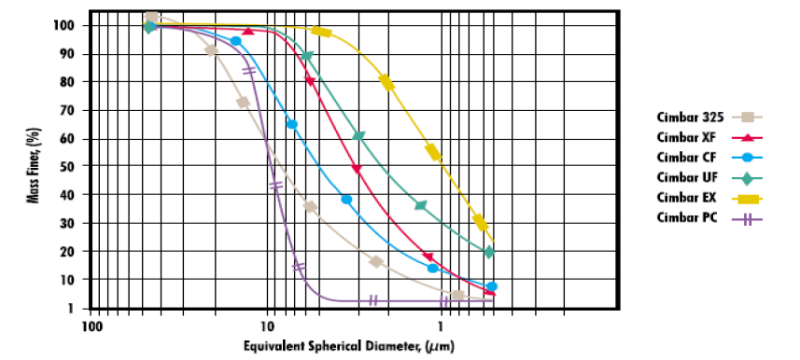

- Particle Size Distribution