Knowde Enhanced TDS

Identification & Functionality

- Base Oil Type

- Metalworking Fluid Type

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Excellent lubricity, tool life and surface finish

- Unlike most synthetics, this fluid can be used to roll/form tap Aluminum and some Steels

- Up to 20% productivity gains over competitors

- Excellent rancidity control

- Rejects tramp oil which extends sump life

- Minimal need for additives

- Provides excellent part visibility

- Low misting

- Mild to skin

- Very low foaming even when used with de-ionized water

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Applications

CIMTECH® 50 - F321 with InSol™ Technology can be used on wrought aluminum alloys (2024, 6061, 7050, 7075), cast aluminum alloys (380, 390), carbon steels, stainless steels, titanium and other exotic alloys. It should not be used on magnesium alloys.

- Concentration

BCG Titration, Total Alkalinity, CIMCHEK™ Test Strip or Refractometer can be used.

The Refractometer Factor is 1.6

Multiply the scale reading obtained on your CIMCOOL® Refractometer by this factor to obtain the mix concentration in percent. Calibrate the refractometer so that it reads 0.0 with water before testing the sample mix. Remove gross contaminants from the sample mixes before testing. A refractometer is only recommended for use in checking the concentration on a fresh charge.

Properties

- Color

- Physical Form

- Appearance

- Clear

- Odor

- Chemical

- Solubility in Water

- 100% Miscible

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (SUS, 100°F, 38°C) | 110.0 | — | — |

| pH Concentrate | 8.2 | — | — |

| Total Chlorine | 0.0 | ppm | — |

| Silicones | None | — | — |

| Weight (60°F, 15.6 °C) | 9.0 | Ib/gal | — |

| Chloride | max. 900 | ppm | — |

| pH Mix 5% (Typical Operating) | 7.5 | — | — |

| Total Sulfur | 0.0 | wt% | — |

Technical Details & Test Data

- Recommended Starting Dilutions

CIMTECH® 50 — F321 with InSol™ Technology is to be mixed with water for use. Always add concentrate to water. Fluid may be more difficult to mix when water temperature is below 55°F (13°C). Add no other materials to the concentrate or mix unless approved by your CIMCOOL® Territory Manager.

Grinding 5% - 10% (1:20 to 1:10)

Machining 5%-10% (1:20 to 1:10)- What is Insol™ Technology

Insol Technology puts Lubricants at the cut zone-tooling interface so that lubrication and cooling are optimized. Since Insol Technology is Water Soluble, this great performance lasts longer due to lower depletion rates. Best of all, Insol Technology can help with tough alloys and even from tapping of aluminum. Using CIMTECH fluids with Insol Technology can Improve machining and grinding ratios significantly compared to conventional fluids.

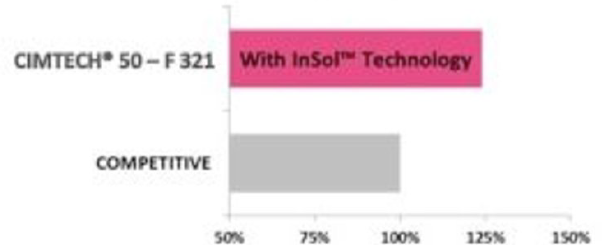

Machining Improvement

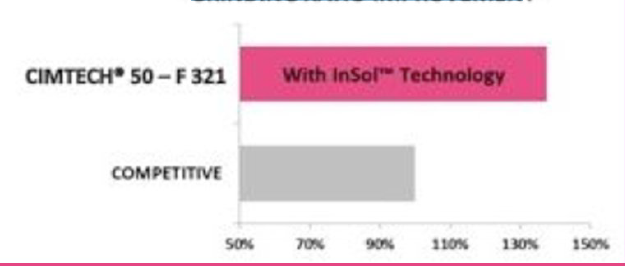

Grinding Ratio Improvement

Storage & Handling

- Handling and Storage

If frozen, product separates. Thaw completely at room temperature and stir thoroughly before use. Inside storage is recommended.