Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Food Ingredients Functions

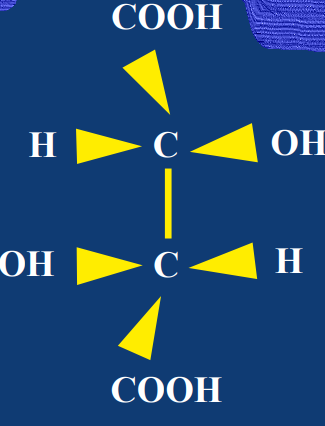

- Chemical Formula

- C₄H₆O₆

- Ingredients

- Tartaric Acid

- Food Additive Number

- E 334, INS 334

- Technologies

- Product Families

- Raw Materials

The tartaric raw materials used in the manufacturing process of the acid come from the grape, as being the natural source of major content in salts derived from tartaric acid. Tradicionally the raw materials in the natural tartaric acid manufacturing process are:

- Calcium Tartrate

- Potassium Bitartrate

- Cream of Tartar.

Calcium Tartrate

- The calcium tartrate is obtained as a by-product from the wine distilleries, once the potassium bitartrate has been transformed.

- It arrives at the factory as small crystals, usually yellow or purple in color that is stored in silos. Its tartaric purity ranges between 45 - 52 %.

Potassium Bitartrate (TARTAR)

- The tartar is the impure potassium bitartrate which crystallizes forming a cap on the walls of the deposits where the wine is stored.

- It arrives at the factory as broken up crusts. Its level of tartaric ranges between 60 – 70 %.

Cream of Tartar

- The cream of tartar is also impure potassium bitartrate. It is obtained principally in the bottom of the tanks where the most of concentrate grape is stored or where the wine is also stored, which has previously been put through a process of refrigeration to eliminate the salts which after bottling could precipitate in time.

- This product arrives at the factory in the form of a damp crystalline paste. Its degree of tartaric on a humid basis ranges between 50 – 60 %.

- Physical Aspect

- Tartaric acid occurs as colorless or translucent monoclinic crystals or as a white fine to granular crystalline powder. It is odorless and has an acid taste.

- Tartaric acid is stable to air and light.

- Chemical Name & Structure

L+ Tartaric Acid (Butanodioc 2, 3-dihydroxy acid).

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Manufacturing Process

- Comercial Química Sarasa S.L. is the largest manufacturer in the production of natural tartaric acid at the world level. It counts on such tradition, experience and human capital that permits it to produce annually about 12,000 MT of natural tartaric acid divided between its two plants.

- The raw materials are stored in the silos. The natural tartaric acid manufacturing process consists in the transformation of the raw materials (natural tartaric salts) in acid medium. Once the reaction has finished, the impure tartaric solutions filtered are concentrated to obtain a red crystalline mass.

- The red crystals obtained are dissolved in water and purified.

- Once purified, the tartaric solutions are concentrated to obtain a white crystalline mass. The moist white crystals obtained are dried.

- After drying, the tartaric acid crystals are sieved to select different crystal sizes.

- The natural product finished, once all the strict quality control tests have been passed, is stored in a fresh and dry place waiting for its subsequent transportation.

- Applications

Pharmaceutical and cosmetic industries:

- It is very useful the tartaric acid optical activity and its capacity of forming complexes.

- The mixture of tartaric acid and sodium salts it is the base for the effervescent formulations to prepare antacids, fruit salts and artificial sweeteners.

Gypsum industry: It is used for retarding the gypsum hardening

Wine-making industry: It is used for correcting the acidity in the winemaking process.

Chemical industry: It is used for preparing tartars and as a chelating agent.Food industry:

- The tartaric acid stabilizing power, inhibiting microbial activity, endows it with excellent properties as a food preservative for meat and fish.

- It is used in the manufacturing of sweets and gelatines.

- It is used as a yeast in bakery.

- To prepare efferverscent drinks.

- In the cheese making process.

- In fat industries.

- It is used as an acidulant in refreshing soft drinks.

Other industries:

- It is used as a color polishing, fiber smoothing, textile printing and dye manufacturing.

- To regulate pH in the photographic industry.

- In galvanotechnics.

Properties

- Soluble in

- 19.6, 0.59

- Physico-Chemical Properties

- Specifications

- Solubility in Water

Temperature (°C) Solubility (g/100 g H2O)

0 115 5 120 10 125 20 139 30 156 40 176 50 195 60 218 70 244 80 273 90 307 100 343

| Value | Units | Test Method / Conditions | |

| Molecular Weight | 150.09 | — | — |

| Melting Point | 168 - 170 | ºC | — |

| Specific Rotation (Aquous Solution 20%, w/v, [α]20ºD+) | 12.0 | — | — |

| Value | Units | Test Method / Conditions | |

| Purity | min. 99.90 | % | — |

| Loss on drying | max. 0.20 | % | — |

| Residue on ignition | 0.02 | % | — |

| Sulphates | 150.0 | ppm | — |

| lron | 5.0 | ppm | — |

| Heavy metals | 10.0 | ppm | — |

| Chlorides | 10.0 | ppm | — |

| Arsenic | 1.0 | ppm | — |

| Oxalic acid | 200.0 | ppm | — |

| Calcium | 200.0 | ppm | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

Identification Number Grade Granulometric range (microns) Mean value 1 Very fine granular 600 - 250 90% 2 Fine granular 900 - 315 90% 3 Standard granular 1200 - 500 87% P Powder - Eno 400 - 125 90% 24 Very fine powder < 100 45% 14 Extrafine powder < 200 90% 15 Very extrafine powder < 63 70%

Packaging & Availability

- Packaging Type

- Packing

- 25 kg polypropylene raffia bags with polyethylene inner bag for food industry.

- 25 kg paper bags with polyethylene inner bag for food industry.

- 1,000 kg polypropylene raffia big bags with polyethylene inner bag for food industry.

- 500 kg, 1,000 kg, 1,200 kg and 1,250 kg shrinkwrapped pallets.