Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Precision Chopped Fiber

- Light weight, high strength, high aspect ratio

- Uniform coating on fibers

- Easy insertion into existing systems

- Increased conductivity & shielding performance

- Improvements in strength & structural integrity through lower loading levels

- Integrates easily into high volume manufacturing systems

- Improved capabilities of flexible plastics & composites manufacturing

- Improved corrosion resistance

- Lower density than nickel coated graphite

Applications & Uses

- Applications

- Composites Processing Methods

- Application

- Plastics

- Paints

- Elastomers

- Resins

- Adhesives

- Prepregs

- Gaskets

- Surface Films

- Construction Materials

- Application and Advantage

Our high-aspect ratio, low density, and corrosion resistant Precision Chopped Nickel coated carbon fibers have advantages in many applications including:

Application Advantage Typical fiber lengths Typical loading levels Typical conductivity levels Paints Easily dispersed, high conductivity at low loading, paint can be applied with many conventional methods including brush, roll & spray 0.1 to 0.5mm 2% - 20% 10-1000 S/cm Gaskets & Sealants High conductivity and shielding at lower density and lower loading levels than other conductive fillers. Corrosion resistant and physically robust conductors 0.1 to 1mm 2% - 40% 1-1000 S/cm Adhesives High conductivity with low volume loadings, adhesive system retains strength properties 0.1 to 0.5mm 2% - 20% 1-100 S/cm Injection molding High conductivity with good flow properties, small robust fiberbased conductors provide good detail replication 0.1 to 2mm 2% - 50% 1-100 S/cm Compression molding High conductivity with good flow properties, small robust fiberbased conductors provide good detail replication 0.1 to 2mm 2% - 50% 1-1000 S/cm Additive manufacturing High conductivity with low loading. Suitable for additive manufacturing processes and equipment 0.1 to 0.25mm 2% - 15% 0.1 - 10 S/cm

Properties

- Physical Form

Technical Details & Test Data

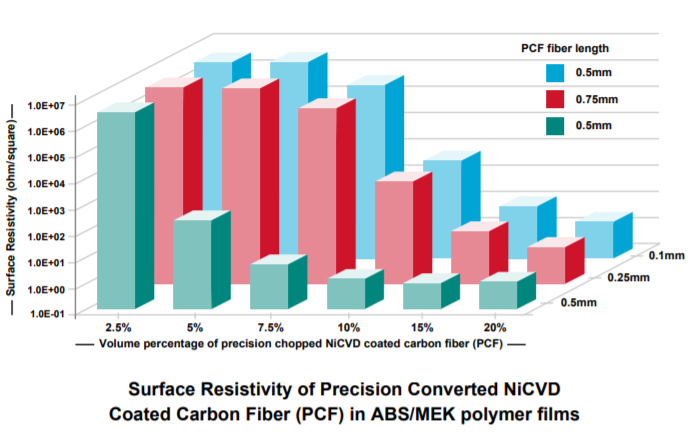

- Surface Resistivity

Packaging & Availability

- Availability

- Nickel coating levels: 20%, 30%, 40%, 55%

- Lengths: 0.1mm, 0.25mm, 0.5mm, 1mm, 2mm

- Available unsized or with a range of sizing chemistries