Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Base Fiber

- Standard Modulus

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Advantages

- Highly conductive

- Uniform consistency

- Easily dispersible

- Low density

- High aspect ratio

- High strength

- Thin, robust, & ductile nickel coating

- High purity

- Corrosion resistant

- Wide range of nickel coating levels and lengths

Applications & Uses

- Applications

- Application and Advantage

Application Advantage Typical fiber lengths Typical loading levels Typical conductivity levels Coatings Easily dispersed, high conductivity at low loading, PC2F based coatings can typically be applied with conventional methods 0.1 to 0.5mm 0.2%- 20% 0.1-1000 S/cm Gaskets & Sealants High conductivity and shielding at lower density and lower loading levels than other conductive fillers. Corrosion resistant and physically robust conductors 0.1 to 1mm 2% - 40% 1-1000 S/cm Additive manufacturing High conductivity with low loading. Suitable for additive manufacturing processes and equipment 0.1 to 0.25mm 2% - 15% 0.1 - 10 S/cm Molding High conductivity with good flow properties, small robust fiberbased conductors provide good detail replication 0.1 to 2mm 2% - 50% 1-100 S/cm Adhesives High conductivity with low volume loadings, adhesive system generallly retains strength properties 0.1 to 0.5mm 2% - 20% 1-100 S/cm

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density Typical | 2.15 | g/cc | - |

| Length Nominal | 0.1 | mm | - |

| Nominal Nickle Coating Level | 20 | wt% | - |

Technical Details & Test Data

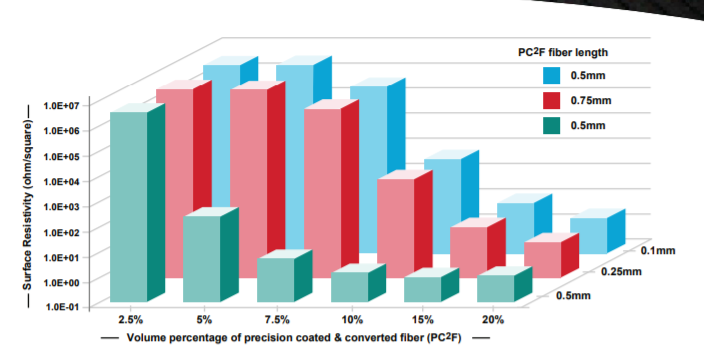

- Surface Resistivity

Surface Resistivity of Precision Coated & Converted fiber (PC2F) in ABS/MEK polymer films

Surface Resistivity of Precision Coated & Converted fiber (PC2F) in ABS/MEK polymer films