Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Sizing Type

- Silane

- Glass Type

- E/ECR/TM

- Technologies

- Product Families

- Identification

Example: ECT 468A-2400

ECT: Boron Free E – Glass

468A : CPIC sizing reference

2400: Linear nominal weight of roving (Tex)

Features & Benefits

- Labeling Claims

- Materials Features

- Product Benefits

- Good insulation properties

- Good performance for weaving and knitting

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Composites End Use

- Composites Processing Methods

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Filament Diameter | ±1 | % | ISO1888 |

| Filament Diameter | 14 | μm | — |

| Moisture Content | max. 0.10 | % | ISO3344 |

| Tensile Strength (<1200Tex) | min. 0.35 | N/Tex | ISO3341 |

| Tensile Strength (≥1200Tex) | min. 0.30 | N/Tex | ISO3341 |

| Linear Density | 600 | tex(g/km) | — |

| LOI | 0.5 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Certifications

- ISO 9001

- ISO 14001

- OHSAS 18001

Packaging & Availability

- Packaging Type

- Packaging

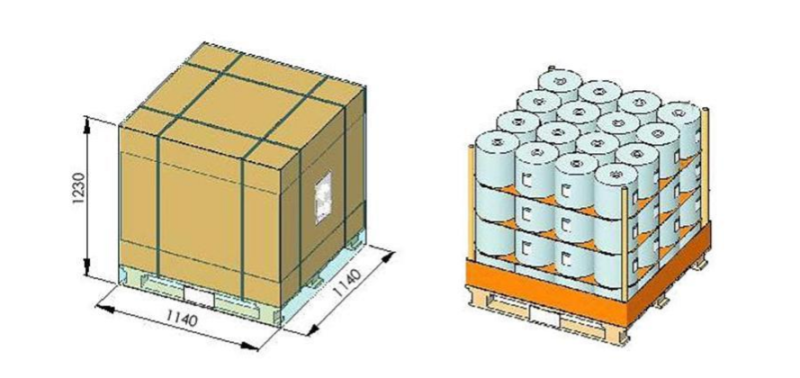

Each roll of roving is wrapped by shrinkage packing or tacky-pack, then put into pallet or carton box, 48 rolls or 64 rolls each pallet.

- Pallets Characteristics

Product Levels per Pallet Rovings per Pallet Rovings per Level Pallet Dimensions L x W x H (mm) Net Weight approx. (Kg)

Direct Roving 3 48 16 1140 x 1140 x 940 816 Direct Roving 4 64 16 1140 x 1140 x 1230 1088

Storage & Handling

- Storage

The rovings should be stored away from heat and moisture, and in their original packaging. The best conditions are: temperatures between 15 and 35 ºC; humidity between 35 and 65 %. If the product is not stored under these specifications, it is advisable to condition it in the workshop for at least 24 hours before use, to prevent condensation. The pallets can be stored in 2 levels (1/1). CPIC recommends that the material be used according to FIFO (first in, first out) method. It is recommended the use of a spacer plate (10mm) between the pallets.