Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- CAS No.

- 1332-09-8

- EC No.

- 603-719-3

- Technologies

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Coating Type

- Interior Paints

SafSil® pumice provides enhanced qualities in interior paints. By proper choice of pumice particle size, the following properties can be improved:

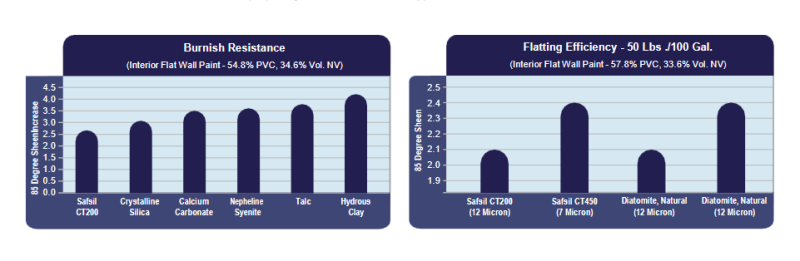

• Burnish resistance

• Flatting

• Abrasion resistance

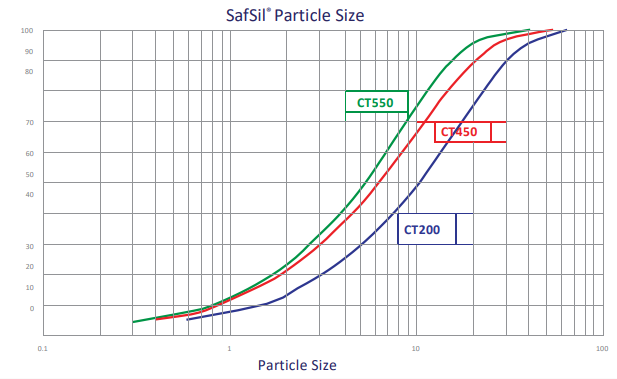

• Touch-upThe larger particle sizes of SafSil® CT200 contribute most to improving these properties. SafSil® has also demonstrated excellent efficiency replacing natural diatomite in many paints.

- Exterior Paints and Stains

SafSil® is used to formulate exterior paints, primarily to improve the following properties:

- Tint retention

- Frost resistance

- Uses

- Floor Paints - The hardness, chemical resistance, and abrasive qualities of SafSil® pumice make it an ideal candidate for floor and deck coatings. SafSil® can also be used in driveway sealers. The material contributes to rheology and helps film reinforcement. Larger particle size Navajo Brand® pumice grades are used for non-skid floor coatings. Grades such as Grade ½ and Grade 3 have been used successfully.

- Primers and Undercoats - SafSil is used for both architectural and industrial primers. The low soluble salt content of SafSil , as measured by the ASTM D2448 Test Method, imparts improved corrosion properties to maintenance primers. Primers containing SafSil® demonstrate excellent “tooth” for subsequent topcoat adhesion. Even though SafSil® is a relatively hard material, with a Mohs hardness of 5.5-6.0, primers produced with SafSil® exhibit very good sanding qualities.

- Powder Coatings - The coarser CT200 and CT 450 grades work well for gloss control. SafSill® possesses greater Mohs Hardness than the more commonly used fillers in powder coatings. Dosages less than ten percent have increased film hardness and scratch resistance. Although SafSill® is relatively hard, it does not present any equipment wear issues. The exterior performance of SafSill® is well proven. Color and gloss retention are positive attributes of the material.

- Tennis Court Coatings - SafSil® is used successfully in tennis court systems. The material provides film reinforcement, sheen control and outstanding tint retention.

- Traffic Paint - SafSil® is efficacious for traffic paints. The hardness and abrasion resistance of the material makes it ideal for replacing some of the calcium carbonate in most systems. SafSil® can replace diatomite used by some formulators for flatting. Improved performance will occur due the obtaining increased “free binder”.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Median Particle Size | 12 | Micron | — |

| Hardness | 5.5 - 6.0 | Mohs Scale | — |

| pH Value (10% in Water) | 9 | — | — |

| Bulk Density | 48 | Lbs./Cu. Ft. | — |

| Specific Gravity | 2.34 | — | — |

| Hegman Grind | 2 | — | — |

| Oil Absorption | 26 | — | ASTM D281 |

| GE Brightness | 78 | — | — |

| Wt./Gal | 19.5 | — | — |

| Refractive Index | 1.5 | — | — |

| Moisture Content | max. 1 | % | — |

| Silicon Dioxide (SiO2) | 73 | wt. % | — |

| Aluminum Oxide (Al2O3) | 12 | wt. % | — |

| Potassium Oxide (K20) | max. 4 | wt. % | — |

| Sodium Oxide (Na2O) | max. 4 | wt. % | — |

| Calcium Oxide (CaO) | max. 2 | wt. % | — |

| Magnesium Oxide (MgO) | max. 2 | wt. % | — |

| Titanium Dioxide (TiO2) | max. 2 | wt. % | — |

| Ferrous Oxide (Fe2O3) | max. 2 | wt. % | — |

Technical Details & Test Data

- SafSil® Particle Size