Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Surface Preparation Required

- ICRI CSP-3

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Benefits

- Ready for full services in one hour

- 100% Active, Low Viscosity for excellent flow and concrete penetration

- Complete system can be build-up to ¼" thickness within 1day.

- Very good chemical resistance

- UV resistance

- Excellent for quick resurfacing

- Elevated temperature resistance

- Hot tire resistance

- Good scratch and wear resistance

Applications & Uses

- Markets

- Application Area

- Compatible Substrates & Surfaces

- Typical Uses

- Pharmaceuticals

- Hospitals

- Laboratory

- Restaurants

- Retail Stores

- Laundry Facilities

- Schools

- Hotels

- Coverage

MMA is thickness driven apply at 15-20 mils on average is required. 1 gallon covers 80-100 sq.ft. at 15-20 mils. Important: Proper ventilation is required to move the sur- face air to ensure proper curing.

- Limitations

This product is best suited for application in temperatures between 60°F and 90°F. Certain colors appear white when scratched such as blue based. Higher temperature will result in faster dry time or poor workability. Color may vary due to batch to batch variation, especially in higher temperature. MMA is sensitive to too much air flow or not enough air movement. MMA cannot tolerate any moisture present in concrete. Do not overwork MMA. MMA is driven by proper thickness – adhere to recommended spread rate/film thickness.

- Check the Concrete

Concrete must be structurally sound and free of curing membrane, paint or other sealer. If you suspect that the concrete has been previously sealed, call Crown Polymers technical support for further instructions.

- Check for Moisture

Concrete must be dry before application of this floor coating material. Concrete moisture testing must occur. Calcium chloride testing or in-situ relative humidity testing is recommended. Test methods can be purchased at www.astm.org, see ASTM F1869-11 or F2170-11, respectively or follow manufacturer’s instructions. Readings must be below the defined threshold as specified for each Crown Polymers system to be installed directly to the concrete substrate. Concrete moisture vapor transmission cannot supersede 3lb or more than 75% relative humidity.

*Note: Although testing is critical, it is not a guarantee against future problems. This is especially true if there is no vapor barrier or the vapor barrier is not functioning properly and/or you suspect you may have concrete contamination from oils, chemical spills or excessive salts.

- Check the Temperature & Humidity

Floor temperature and materials should be between 65°F (18°C) and 90°F (32°C). Humidity must be less than 80%. DO NOT coat unless floor temperature is more than (5ºF) over the dew point.

- Application

- SURFACE PREPARATION - This product requires preparation to perform as expect- ed. Substrate must be mechanically profiled (ASTM 4259- 83), clean, sound, dry, and contaminate free.

- APPLICATION EQUIPMENT - Tools: 3” Disposable brush, low speed drill (450rpm) with 3.5" Jiffler blade, 3/8” nap non-shedding phenolic core roller. Note: A 1/8” V-notch rubber squeegee is only required for self-leveling applications.

- MIXING - The temperature of the material should be between 60-80ºF (15-25ºC).

- Premix CrownMMA™ well to ensure liquid uniformity.

- DO NOT THIN CrownMMA™.

- Thoroughly mix CrownBPO™ into CrownMMA™.

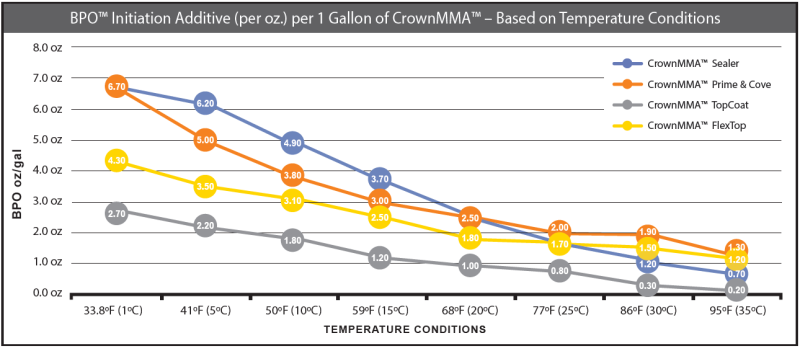

Note: CrownBPO™ (benzoyl peroxide) is the initiation system required to harden CrownMMA™. CrownBPO™ must be completely dissolved to ensure rapid curing of CrownMMA™. Boxing is very helpful when installing. This will ensure the colors are consistent.

TEMPERATURE FOR BPO ADDITIVE 33.8ºF (1ºC) 41ºF (5ºC) 50ºF (10ºC) 59ºF (15ºC) 68ºF (20ºC) 77ºF (25ºC) 86ºF (30ºC) 95ºF (35ºC) CrownMMA™ Sealer 6.7 oz 6.2 oz 4.9 oz 3.7 oz 2.5 oz 1.7 oz 1.2 oz 0.7 oz - ROLL ON - Priming concrete is critical. After mixing all contents as instructed, immediately pour out into a ribbon on the surface. Spread the material out evenly and check for desired film thickness by using a wet-film thickness gage. Roll spread then quickly back roll. Flat squeegee is not recommended for use with CrownMMA™. Material is ready for full services in one hour.

IMPORTANT : Proper ventilation is required to move air to ensure proper curing. Observe all fire hazards, legal, and health and safety precautions when handling or storing solvents, particularly in confined spaces. Make sure the working area is well ventilated at all times during application and curing times.

CLEAN-UP: Clean-up mixing station, tools and application equipment immediately after completion. Use CrownMMA cleaner.

DISPOSAL - Dispose all excess materials, packaging, and other waste in accordance with federal, state, and local regulations.

Properties

- Appearance

- Satin

- Physical Properties

- Chemical Properties

| Value | Units | Test Method / Conditions | |

| Adhesion (Concrete, Concrete Failure) | min. 400 | PSI | ASTM D7234 |

| Density | 8.0 | lb/gal | - |

| Dry to Touch (70ºF, 50%RH) | 1.0 | hour | - |

| Full Cure | 1.0 | hour | - |

| Hardness (Konig, 3 mils) | 110.0 | - | ASTM D4366 |

| Application Temperature | min. -20 | ºF | - |

| Pot Life (70ºF, 50% RH) | 20.0 | minutes | - |

| Recoat Time (70ºF) | 1.0 | hour | - |

| Tensile Elongation | 0.8 | % | DIN EN ISO 527 |

| Tensile Strength | 1276.0 | PSI | DIN EN ISO 604 |

| Theoretical Coverage (15-20 mils WFT) | 80 - 100 | ft²/gal | - |

| VOC Content | max. 100 | g/l | - |

| Water Absorption | max. 0.1 | % | ASTM D570 |

| Value | Units | Test Method / Conditions | |

| Alkali (70ºF) | Excellent | - | - |

| Hydrocarbons Content (70ºF) | Good | - | - |

| Inorganic Acids Content (70ºF) | Good | - | - |

| Organic Acids Content (70ºF) | Good | - | - |

| pH Range (70ºF) | 4 - 13 | - | - |

| Solvents (70ºF) | Good | - | - |

Safety & Health

- Handling/Safety

DANGER. MMA is highly flammable. Eye and skin irritant. May cause dermatitis and sensitization. Always read and understand the product SDS. Avoid contact with eyes, skin or clothing. Avoid breathing vapor, mist or spray. Always wear an OSHA approved respirator when using this product. Use with good ventilation.

- First Aid

In case of contact:

- Eyes: Immediately flush with water for at least 15 minutes.

- Skin: Immediately remove from skin with dry cloth followed by thorough washing with soap and water.

- Inhalation: Remove to fresh air. If breathing is difficult, give oxygen.

- Ingestion: Immediately call a Poison Center/Doctor. Do NOT induce vomiting. If vomiting occurs naturally, lie on your side, in the recovery position.

- Caution

Always read and understand the specific product data guide and SDS sheets before using this product. For more information contact Crown Polymers.

Packaging & Availability

- Packaging Type

- Packaging

Available in 1 gallon and 5 gallon pails.

Storage & Handling

- Storage

This product has a maximum shelf life of one year when stored off the ground in a dry area at 50º to 90ºF, in the original sealed container.