Knowde Enhanced TDS

Identification & Functionality

- Enzyme Type

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Beta-glucanase

- Technologies

Features & Benefits

- Food Ingredients Features

- Characteristics

- When the content of beta-glucans in a malt is very high and/or its natural enzyme system is poorly developed (poorly disaggregated malts), the use of relatively thermostable external enzymes makes it possible to avoid problems in filtration and in the stability of the beer. BETAZYME-1250 L, used at adequate doses, allows the beta-glucan content of a must to be hydrolysed by 80%, the most abundant hemicellulasic component in barley and, at the same time, the one that causes the most problems during the process.

- Likewise, its high hemicellulasic activity acts very favorably in the release of water fixed to the insoluble arabinoxylans of the bagasse and in the reduction of the viscosity of the must caused by the dissolution of the soluble arabinoxylans.

- Advantages

The most important advantages of using BETAZYME 1250 L are the following:

- Better use of the extract.

- Reduction of back pressure in must filtration (press filters).

- Decrease in the number of low cuts in the lauter tun.

- Increases from 20 to 50% in the number of Hectoliters of beer filtered per cycle.

- Reduction of the EBC turbidity value in beer.

Betazyme 1250 l does not contain protease activity. Said enzyme is completely destroyed after boiling the must.

Applications & Uses

- Markets

- Applications

- Dosage and Instructions for Use

- BETAZYME 1250L is dosed from 100 grams to 200 grams per ton. of malt, according to its characteristics. BIOCON's Technical Department is at the customer's disposal to carry out laboratory brewing with malt samples, as a preliminary step to plant optimization.

- BETAZYME 1250L is added to the mixing kettle at the start of proteolysis. It is convenient to mix the enzyme with water (without chlorine) until completing about 10 liters and then add it slowly to the filling.

Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Beta-glucanase Activity | 1250.0 | per gram | - |

| Lead | max. 5 | ppm | - |

| TVC | max. 50,000 | CFU/g | - |

| Coliforms | max. 30 | CFU/g | - |

| Salmonella | Absent | /25g | - |

Regulatory & Compliance

- Compliance

This product meets the requirements for food grade enzymes set by the FCC/JECFA.

Technical Details & Test Data

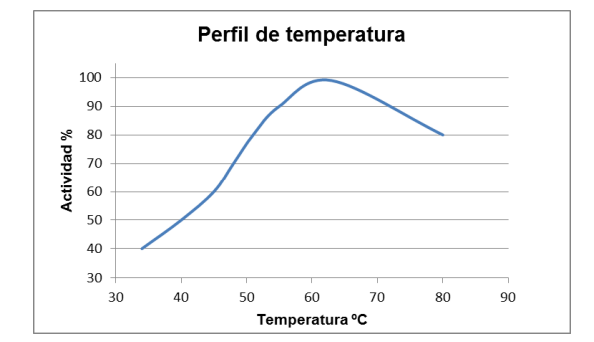

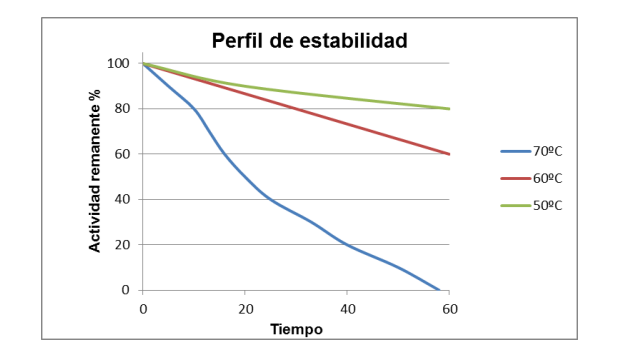

- Activity Parameters

Packaging & Availability

- Packaging Type

- Packaging

BETAZYME 1250L is supplied in a 25Kg opaque polyethylene container.

Storage & Handling

- Storage

- The long-term stability of BETAZYME 1250 L is enhanced below 10ºC.

- One is not appreciated significant loss in activity with storage for 3 months at 20°C.