Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Components

- 1

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features & Benefits

High Performance Waterproof Protection

- Rubber Seal is an ultra-tough, super-waterproofing, alkali-resistant, water-based copolymer elastomeric coating

- It's like liquid synthetic rubber

- Sticks like an epoxy coating

Works Great Over

- Concrete

- Stucco

- Masonry

- Wood

- Fabrics

- Metal

- Natural Stones

- Foam

- Asphalt

- Mineral Surface Modified Bitumen

- Smooth Surface Modified Bitumen

- Smooth Surface Built-Up Roof

- Mineral Surface Built-Up Roof

- Granulated Asphaltic Surfaces

Benefits

- Rubber Seal is uniquely formulated to waterproof and protect a variety of substrates. Designed as a single-part water based coating with the highest performance in coastal, temperate, humid, hot, and extreme alkaline envi-ronments.

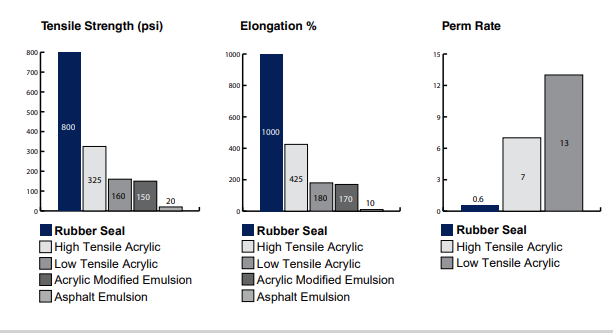

- Rubber Seal creates a tough, long-lasting protective membrane that remains flexible Over time, even under adverse conditions. Its elongation and tensile strength provide unsurpassed resistance to maintenance traffic, weather conditions, and wear.

- Unlike similar generic coatings, Rubber Seal is formulated to have exceptional adhesion to a variety of substrates. lts proprietary formula features copolymer elastomeric resins to produce a seamless, flexible, durable membrane that displays exceptional weathering ability and good UV resistance.

Save Money

- Light Weight-Install Over Existing Surface

- Restores Existing Roof-Avoid a Costly Tear-Off

- Blocks UV-Stops Deterioration

- Cures Fast-Complete the Job Faster

- More Coverage-Waterproof at the Lowest Cost

- Considered Maintenance-Write-Off Coating This Year

Due to its light weight, Rubber Seal can be applied over existing roofs without having to tear them off. Rubber Seal has better coverage and waterproofs better than the same amount of acrylic or asphalt. During the spray application, Rubber Seal cures quickly, allowing faster job completion.

Extend Waterproofing Life

- Tenacious Adhesion-Sticks Firmly to Substrate

- High Tensile Strength-Prevents Cracking & Crazing

- Low Perm Rate- Keeps Liquid Out

- Breathes-Lets Water Vapor Pass

- Resists Alkali-Apply in Low-pH Environment

- Resists Acid-Withstand Acidic Rain

- Resists Salts- Apply Near the Ocean

Rubber Seal creates superior waterproofing, forminga vapor barrier at 0.6 perms. This is more than 10 times better than asphalt, and 20 times better than acryliCs. Rubber Seal will minimize problems in ponded areas. Also, Rubber Seal has tenacious adhesion to the substrate, and sticks like an epoxy glue. Unlike asphalt coatings, Rubber Seal is uv resistant. t also resists alkali/salt, to extremes of pH of 13, and is highly resistant to acid.

Protect the Environment

- Few Anti-microbial Additives-Keep Runoff Clean

- No Solvents, Low Voc-Avoid Harmful Fumes

- Non-toxic-Preserve Building Health

Rubber Seal is water-based for easy cleanup and low odor. It contains low VoCs to keep the air healthier for people to breathe. Because of the low perm rate and smooth top coats, Rubber Seal systems require few anti-microbial agents. Also, Davlin products contain NO zinc additives and have a low erosion rate, which contributes to cleaner waste-water in Our streams, rivers, Jakes, and bays.

Applications & Uses

- Applications

- Application Area

- Applications & Uses

Recommended Uses

- Roof Repair + Restoration

- Gutter Repair

- Below Grade

- Foundation Waterproofing

- Fence Post Waterproofing

- Basements

- Anti-CorTOSIon

- Mobile Home +RV Roof

- Metal Rust

Recommended finish: Sunshield (Top Coat) to further boost the reflectance and keep the surface extra clean.

Installaton

Remove all contaminants and loose material, such as dust, dirt, oil, silicone, release agents, ho h t frtrel AE i r 94 i inclement weather, including rain, f SHIPMENT AND STORAGE. Do not store material at temperatures below 50 F. Flush all equipment with water before use. Stir Rubbber Seal thoroughly until uniformly blended, but avoid excessive mixing to prevent air entrapment. elow 45 mis mist, or freezing temperatures.Protect from freezing during shipment and storage.

Spray &Roller Application

- Apply a wet coat in even, parallel passes, overlapping each pass 50% to avold holidays, bare areas, and pinholes. Cross-roll or spray at a right angle to the first pass. Porous concrete will require more than one pass. On rough surfaces, back roll the first coat to ensure that coating is pushed deep into surface.

- Apply 1 coat of Rubber Seal at 1 gallon per 100 square feet, dry film thickness of 8.5 mils. Allow 4-8 hours to coating, none of the coatina will adhere to the thumb Appiv sercond thirc and fourh coote e specification. For additional durability, roofing granules may be broadcast into the final coating application at the rate of 35-40 lbs per 100 square feet. Clean equipment with water or water and detergent immediately after use.

Equipment

Changes in pressure, tip size, and equipment may be needed for proper spray characteristics.

- Alrless: Airless: Standard equipment such as Graco Bulldog Hydra Spray 30 or 45:1 pump with a 0.025-0.031 inch reversible fluid tip.

- Conventional: Industrial equipment such as Binks 11:1 Satun pump or equivalent with air control cut-of, a malerial nose 3/4 ncn iDminimum and an air hose 12 inch lD and su-/5 psi air pressure minimum. Heavy mastic spray gun such as Binks 7E2 with 1/4 inch fluid tip or larger and slotted nozzle.

- Brush or Roller: Suitable for waterborne coating. Multiple coats may be required to achieve specified DFT. Roller nap will vary according to texture of substrate, typically a 3/4 inch nap will work.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Adhesion (Concrete) | 400.0 | psi | ASTM D413 |

| Alkali Resistance | No Effect | — | Fed. Spec. TTC-555B, GSA ex.1 |

| Application Temperature Air and Surface | 45 - 100 °F | — | — |

| Availability | Shipped Nationaly &Intemationally | — | — |

| Clean Up (75°C) | Water | — | — |

| Curing Mechanism (75°C) | Air Dry | — | — |

| Dry Film Thickness (DFT, 100 ft²/gal) | 8.5 | mils | — |

| Drying Time to Re-Coat (21°C) | 2022-04-08 | hours | — |

| Flash Point | min. 215 | °F | SETA |

| Heat Stability | No Viscosity Change | — | Fed. Std. 141 [6051], 160°F for 10 days |

| Moisture Vapor Transmission | 0.6 | pems | ASTM E96, Proc. B, 20 mils DFT |

| Recommended System DFT | 16 - 48 | mils | — |

| Resistance to Ponded Water (75°C) | No Blisters, No Film Degredation | — | — |

| Resistance to Wind-Driven Rain (min.100 mph) | No Weight Gain | — | Fed. Spec. T-C-555B, 4.4.7 min. 95 mph req. |

| Salt-Spray Resistance | No Rusting | — | ASTM D1654 |

| Service Temperature | 32 - 200 | °F | — |

| Solids by Volume | 50 - 54 | % | ASTM D2597 |

| Solids by Weight | 49 - 53 | % | ASTM D2369 |

| Tensile Elongation (At Break) | 1000 | % | ASTM D2370, 1 in./min. |

| Tensile Strength (75°C) | 800 | psi | ASTM D2370, 1 in./min. |

| Viscosity (Stormer K.U.) | 95 - 110 | KU | ASTM D562 |

| Volatile Organic Compounds | max. 50 | g/L | US EPA Reference Method 24 |

Technical Details & Test Data

- Performance Data

Guaranteed performance: 10 Year Material Warranty

Safety & Health

- Precautions

Caution

- If surface and roof temperatures are between 50° 70°F then Rubber Seal may be applied in 1 thick coat of 24 wet mils at a rate of 1.5 gallons per 100 square feet.

- Do not attempt to apply Rubber Seal in thick layers when temperatures are above 70 F. This can result in blistering caused by the top layer quickly skinning over, leaving uncured Rubber Seal underneath. Rubber Seal is black and its unique resins allow it to dry faster than gray or white coatings, especially in warm, windy weather.

- When applying polyester fabric. Be careful to apply coating in small areas at a time to ensure that the coating is still wet enough to embed the sheets.

Packaging & Availability

- Packaging

1,5,55, 275 gallons.

Storage & Handling

- Shelf Life

- 3 years if properly stored