Knowde Enhanced TDS

Identification & Functionality

- Pigment Type

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Product Background

Ezentus Pigments from DayGlo are a new class of formaldehyde-free, high performance fluorescent pigment.

Maintaining function and value may be the most challenging aspect of designing safe, non-toxic products. Ezentus, DayGlo’s newest fluorescent pigments have met this challenge in a safe and responsible way. Relying on innovative materials and on pioneering new manufacturing processes, Ezentus pigments are about connecting "what's needed" with "what's possible". Userfriendly materials that eliminate chemicals of concern and make no compromises in performance or value. When compared to the class-leading formaldehyde containing pigments, Ezentus pigments distinct advantages include:- Formaldehyde Free

- Improved Thermal Stability

- Migration Free

- Improved lightfastness

Applications & Uses

Properties

- Typical Properties

- Solvent Compatibility

Alcohols Methanol 2 Ethanol 3 Propanol 4 n-Butanol 4 Diacetone Alcohol 2.5 Ketones Acetone 4 MIBK 4.5 MEK 4.5 Cyclohexanone 4.5 Esters Ethyl Acetate 4.5 Diethylene Glycol Monobutyl Ether Acetate 5 Isopropyl Acetate 5 Isobutyl Isobutyrate 5 Butyl Acetate 5 EB Acetate 5 Glycols & Glycol Ethers PEG 400 3.5 Propylene Glycol 3.5 Propylene Glycol Monomethyl Ether 3.5 Triproylene Glycol Monomethyl Ether 4.5 Aromatics Toluene 5 Xylene 5 Aliphatics Mineral Spirits 5 Lactol Spirits 5 VM&P Naphtha 5 Plasticizers Santicizer 1411 5 Eastman 1682 5 Hexamoll3 5 Dioctyladipate 5 1-Ferro, 2-Eastman Chemical, 3-BASF - Test Method: 1 g of pigment mixed with 9 g of solvent. Bleed assessed after 24 hrs. at room temperature. 1= Considerable Bleeding, 5= No Bleeding

| Value | Units | Test Method / Conditions | |

| Bulk Density | 20 | lbs/ft³ | — |

| Density | 1.25 | g/ml | — |

| Heat Stability | 250 | °C | — |

| Lightfastness | 3-Feb | BWS | — |

| Mean Particle Size | 2.5 | microns | — |

| Moisture Content | max. 2.0 | % | — |

| Oil Absorption (g/100g pigment) | 54 | gram | — |

| Particle Shape | Spherical | — | — |

| Tg | 150 | °C | — |

| Weight Per Gallon | 10.42 | Lbs./Gal. | — |

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

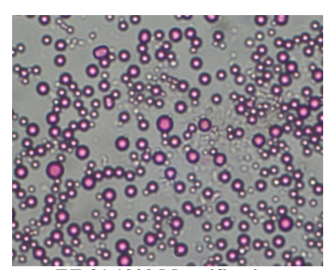

- Particle Morphology

EZ-21 1000 Magnification- EZ Pigments in Polyolefin and EVA Foams

Expanded polyolefins and EVA foams are being used increasingly in sports shoes and apparel because these closed cell foams are stable, durable and chemically resistant. The primary

blowing agent used to produce polyolefin and EVA foams is azodicarbonamide, typically combined with zinc oxide, zinc stearate, stearic acid and reactive peroxides. Formulations of this type produce crosslinked foams that are more stable than similar highly expanded un-crosslinked foams. This crosslinked structure creates a foam that can keep its structure at temperatures approaching the melting point of the base polymer, and in some cases exceed it. One of the added benefits of parts made from polyolefin and EVA foam is the ability to create parts by compression molding methods, including the injection molded foam process.For more details please refer this link: