Knowde Enhanced TDS

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

- The exception cleaner quality is derived from the formulation that acts to release surface tension, meaning the spill is less sticky and therefore easier to clean.

- Repeat clients love this action because there is no greasy residue of the contamination or any of the De-Oil-It ingredients.

- Pollution/contamination is gone, the spill is transformed into elementary chemical elements no longer a threat to the ecosystem and therefore non-detection of hydrocarbons or other harmful items (see list bottom of this web page).

- Degreasers, soaps, detergents, solvents, etc. clean by attaching to the hydrocarbon (fuel, oil, etc.) essentially just moving the contamination from one place to another requiring further hazmat handling, costs and time; a degrader on the other hand disassembles and then transforms hydrocarbons into a detoxified, simpler chemical structure, thereby being much more environmentally responsible and safe.

- Best of all De-Oil-It can be used “in-situ”, meaning the spill treatment can be done on site without necessarily the need to move contaminated soils somewhere else for treatment.

- De-Oil-It is non-hazardous, removes flash point (no fire or ignition is possible, no more odors), while also disassembling large complex hydrocarbon chains into elementary soluble carbon, hydrogen and oxygen. Fuels of all kind such as gasoline, diesel, kerosene, aviation, etc. are no match for De-Oil-It, which instantly decomposes and eradicates fuels.

- De-Oil-It can act as a fire extinguisher or as a fire prevention around fuel spills as De-Oil-It eliminates flash point (spill will not catch fire), and removes odor (fuel vapor is highly flammatory / explosive, and toxic to breathe in) Engineered to be extremely effective on hydrocarbon oil and lipid fats De-Oil-It is an environmentally responsible industrial strength degreaser and general-purpose cleaner.

- It is a non-toxic, non-flammable, non-corrosive system of surfactant and oil solubilizers, which dissolve grease and grime by way of micelle formation.

Applications & Uses

- Markets

- Application Area

- How Does De-oil-it Work?

- DE-OIL-IT breaks down the oils and lipids into millions of molecular / nano sized particles and will not allow them to quickly regenerate like other detergent type cleaners, making clean up easier and more efficient.

- When you rub your finger across a surface cleaned with DE-OIL-IT, you should be able to feel that it is squeaky clean the first time.

- The key to DE-OIL-IT is the technology used to develop a “colloidal micelle.”

- Since DE-OIL-IT is a non-toxic blend of chemicals which works by colloidal formation to remove oil, grease and grime safely, easily and efficiently, it works differently than solvents or caustic-based cleaners.

- Colloidal micelle breaks down long chain hydrocarbon bonds in oils, fats, grease, fuels, etc. and holds them in suspension at the nano scale.

- Individual micelle repel each other; this is how there is no greasy residue left after cleaning.

- This suspension acts as an emulsified layer on top of water and in soil the surfactant properties of De-Oil-It drives the micelle down to layers in soil where bacteria can complete the biodegrading process.

- When a micelle contained in the DE-OIL-IT product comes in contact with a hydrocarbon molecule, the center of the micelle bonds to a similar hydrophobic hydrocarbon.

- It disrupts the attraction to other hydrocarbon molecules and/or to the surface.

- The action of a single micelle is multiplied by billions of other micelles.

- The molecular level emulsification process penetrates highly viscous and sticky materials namely hydrocarbon based, lifting them from the surface to which they adhere.

- De-oil-it Will Degrade the Following

- Fuels: gasoline, diesel, kerosene (heating and aviation quality), etc.

- Hydraulic, transmission (ATF), brake, power steering fluids

- Oil: raw / crude, refined, processed

- TCE - Tricloroethylene

- PCB - Polychlorinated Bi-Phenyls

- PAH - Polycyclic Aromatic Hydrocarbons

- Benzene, Xylene, Toluene, Glycols, pesticides

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

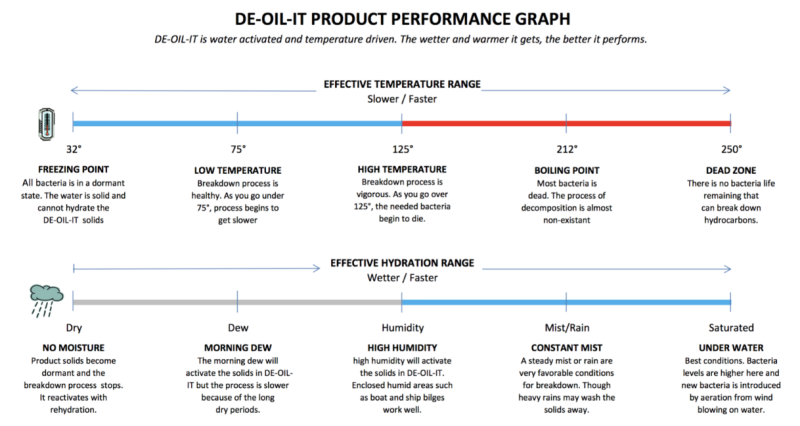

- De-oil-it Product Performance Graph

- Temperature: The top graph illustrates what temperatures DE-OIL-IT performs best in.

- Moisture : The bottom graph shows that the more hydrated DE-OIL-IT gets, the better it performs.

- Decomposition: Petroleum molecules kill the earth's natural decomposing bacteria on contact. The oil remains there indefinitely.

- Chemical Reaction: When DE-OIL-IT is applied to petroleum, it changes it's molecules enough to disarm their bacteria killing ability.

- Bacteria Supply: Once an area is treated, there must be enough fresh bacteria present to eat the petroleum.

- You find them in the air, water and soil.

- Sometimes enclosed areas such as storage tanks become a dead zone and need to have fresh air or water introduced during the remediation period.

- Amount &Viscosity: Results will also vary depending in the amount and viscosity of the petroleum being treated.

- Stronger levels of DE-OIL-IT concentrate may be required.

Packaging & Availability

- Packaging

22oz, 1 gal, 2.5 gal, 5 gal, 55 gal, and 275 gal sizes (pictured below is 1 gallon, 5 gallon, and 22 oz spray bottle).