Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Suitable Lamp Types

LED 460 nm, LED 400 nm

Features & Benefits

- Ready-to-Use Product Features

- Special Features

- compliant with RoHS Directive 2015/863/EU

- halogen-free according to IEC 61249-2-21

- passes ANSI/UL 94 HB Flame Test

Applications & Uses

- Applications

- Typical Area Of Use

-40 - 150 °C

- General Curing and Processing Information

The curing time stated in the technical data was determined in the laboratory. It can vary depending on the adhesive quantity and component geometry and is therefore a reference value.Increasing or decreasing the curing temperature and / or irradiation intensity and / or irradiation time shortens or prolongs the curing time and can lead to changed physical properties.A short irradiation time (preactivation time) results in an open time within which opaque components can be joined.All curing or light fixation parameters depend on material

thickness and absorption, adhesive layer thickness, lamp type and distance between lamp and adhesive layer.Curing until final strength proceeds within 24 hours at room temperature.High temperatures during or after curing can lead to post-crosslinking of the adhesive which influences the physical properties of the bond.Values measured after 24 h at approx. 23 °C / 50 % r.h., unless otherwise specified.

Properties

- Typical Properties

- Processing Parameters

| Value | Units | Test Method / Conditions | |

| Typical Preactivation Time Intensity 200 Mw/Cm² Led 460 Nm | 3.0 | s | — |

| Typical Open Time Intensity 200 Mw/Cm² Led 460 Nm | 15 - 20 | s | — |

| Typical Irradiation Time Intensity 200 Mw/Cm² Led 400 Nm | 40 - 60 | s | — |

| Processing Typical Adhesive Application | Jetting, needle dispensing | — | — |

| Color In Cured Condition In 0.1 Mm Layer Thickness | Yellowish | — | — |

| Transparency In Cured Condition In 0.1 Mm Layer Thickness | Transparent | — | — |

| Value | Units | Test Method / Conditions | |

| Density (Liquid) | 1.13 | g/cm³ | DIN EN ISO 2811-3 |

| Viscosity Liquid | Rheometer | Shear Rate: 10 1/S | 5500.0 | mPa·s | — |

| Thixotropy Index (Liquid | Rheometer) | 3.4 | — | — |

| Maximum Layer Thickness That Can Be Preactivated Delo Standard 21 | Preactivation | 460 Nm | 200 Mw/Cm² | 3 S | Plus | At Approx. +23 °C | 24 H | min. 4 | mm | — |

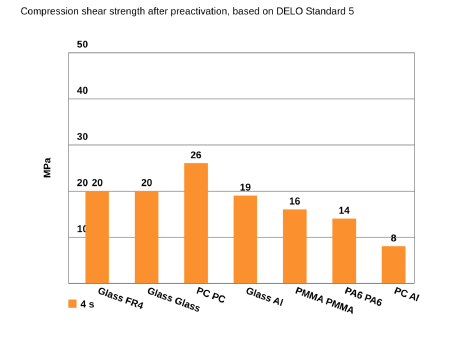

| Compression Shear Strength (Delo Standard 5 | Al | Al | Pretreatment: Laser | Preactivation | 460 Nm | 200 Mw/Cm² | 3 S | Plus | At Approx. +23 °C | 24 H) | 35.0 | MPa | — |

| Compression Shear Strength (Delo Standard 5 | Glass | Al | 400 Nm | 200 Mw/Cm² | 30 S | Plus | At Approx. +23 °C | 24 H) | 20.0 | MPa | — |

| Compression Shear Strength Delo Standard 5 | Glass | Fr4 | 400 Nm | 200 Mw/Cm² | 30 S | Plus | At Approx. +23 °C | 24 H | 20.0 | MPa | — |

| Compression Shear Strength Delo Standard 5 | Glass | Glass | 400 Nm | 200 Mw/Cm² | 30 S | Plus | At Approx. +23 °C | 24 H | 20.0 | MPa | — |

| Compression Shear Strength Delo Standard 5 | Glass | Lcp Gf30 | 400 Nm | 200 Mw/Cm² | 30 S | Plus | At Approx. +23 °C | 24 H | 11.0 | MPa | — |

| Compression Shear Strength Delo Standard 5 | Pa6 | Pa6 | Preactivation | 460 Nm | 200 Mw/Cm² | 3 S | Plus | At Approx. +23 °C | 24 H | 13.0 | MPa | — |

| Compression Shear Strength Delo Standard 5 | Pc | Al | 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | 8.0 | MPa | — |

| Compression Shear Strength Delo Standard 5 | Pc | Pc | 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | 44.0 | MPa | — |

| Tensile Strength 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | 27.0 | MPa | DIN EN ISO 527 |

| Elongation At Tear | 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | 9.0 | % | DIN EN ISO 527 |

| Young'S Modulus Dmta | 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | Type Of Storage: Temp. | Storage Temperature: 205 °C | Duration: 30 Min | 2300.0 | MPa | DMTA EN ISO 400 |

| Shore Hardness D (400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H) | 75.0 | — | DIN EN ISO 868 |

| Glass Transition Temperature Dmta | 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | Type Of Storage: Temp. | Storage Temperature: 205 °C | Duration: 30 Min | 140.0 | °C | — |

| Coefficient Of Linear Expansion (Delo Standard 26 | Tma | Evaluation T: 30 °C - 55 °C | 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H) | 123.0 | ppm/K | — |

| Shrinkage Delo Standard 13 | 400 Nm | 200 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | 4.3 | vol. % | — |

| Creep Resistance Cti M By The Criteria Of | 60 Mw/Cm² | 60 S | Plus | At Approx. +23 °C | 24 H | min. 600 | — | DIN EN 60112 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Converting Table

°F = (°C *1.8) +32

1 inch = 25.4 mm

1 mil = 25.4

1 oz = 28.3495 g

1 MPa = 145.04 psi

1 GPa = 145.04 ksi

1cP = 1 mPa•s

IN = 0.225 lb- Parameters

Storage & Handling

- Storage Life

In Unopened Original Container (at 0 °C To +25 °C) is 6 months