Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Features

- Fast Processing Cycle Time

- Weight Saving

- Low Pressure Molding

- 100% Green Material

- Benefits

- No voc emission

- Ease of storage conditions

- Recyclability

- Drapability

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

LINCORE® PP FF is mainly used for the following applications Automotive, Marine, Trucks, Sports & Leisure, Building, Urban & Industrial Parts, Energy, Tableware

Properties

- Mechanical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength | 60 +/- 8 | MPa | ISO 527 |

| Tensile Modulus | 8.0 +/- 0.4 | GPa | ISO 527 |

| Tensile Elongation | 1.2 +/- 0.1 | % | ISO 527 |

| Flexural Strength | 66 +/- 9 | MPa | ISO 14125 |

| Flexural Modulus | 6.7 +/- 0.6 | GPa | ISO 14125 |

| Flax Content | 40 | % | — |

Technical Details & Test Data

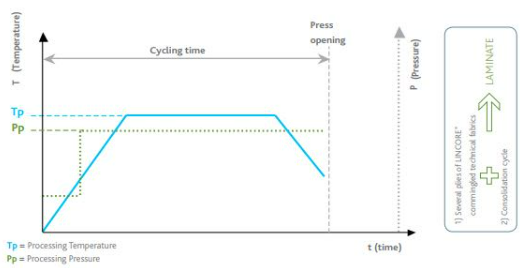

- CONSOLIDATION CYCLE

LINCORE® commingled technical fabrics can be rapidly shaped with a short heating and cooling cycle under a press in order to achieve any type of composite material part. Otherwise, processes such as static press, autoclave, compression molding can also be used.

Packaging & Availability

- Availability

Style Standard width (mm) Weave Roving (tex) Weight (g/m2) Color Warp/Weft LINCORE® PP FF

1000 to 1500 Plain 1/1, Plain 2/2, Twill 2/2, 0° UD and 90° UD 200/1000 153 to 750 Natural