Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Compatible Polymers & Resins

- Applications

MHHPA-KB is a low color, low viscosity, pre-catalyzed epoxy curing agent with a proprietary catalyst that provides the following benefits:

- Easy Handling: Low viscosity liquid gives low viscosity mixes with various epoxy resins

- Convenience: Eliminates the need to add small amounts of catalyst

- Consistency: Prevents potential batch-to-batch differences caused by errors in measuring and properly dispersing small amounts of catalyst

- Low reactivity at room temperature: Provides long working times and pot lives for mixes with epoxy resins

- High reactivity at cure temperature: Gives excellent cure response at cure temperatures, resulting in high crosslinking and relatively high Tg.

- Low color and low color development: Low residual unsaturation gives maximum resistance to yellowing, making it desirable where premium optical and electrical performance are needed in epoxy casting and encapsulation applications.

- Epoxy Formulations

Most applications use between 80-90 parts by weight MHHPA-KB with 100 parts bisphenol A liquid epoxy resins. MHHPA-KB was formulated with a variety of epoxy resins. Viscosity was measured at 25°C, and gel time was measured at 150°C. Samples were cured for 1 hour at 120°C, fol lowed by a post-cure of 1 hour at 220°C, and glass transition temperatures we re measured using a differential scanning calorimeter. The following table summarizes these results:

Epoxy Type MHHPA-KB, phr Viscosity at 25°C, cP Gel Time min Cured Tg, (°C) Standard BPA Liquid Epoxy

Typical89 1210 19 141 Low Viscosity BPA Liquid

EPON 82692 845 17 142 Cycloaliphatic Epoxy

Celloxide 2021P122 139 24 206 Epoxy Phenol Novolac

Epalloy 825096 968 17 134 Epoxy BPA Novolac

EPON SU-2.587 3630 17 150 BPF Liquid Epoxy

EPON 86296 488 15 138

Properties

- Physical Form

- Appearance

- Clear liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity | 1.2 | g/cc | D-102 (ASTM D 4052) |

| Viscosity | 40-100 | cP | D-150F |

| Boiling Point | 145 | ° C | ASTM D86 |

| Flash Point | 149 | ° C | ASTM D93 |

| Molecular Weight (Average) | 170 | — | — |

Technical Details & Test Data

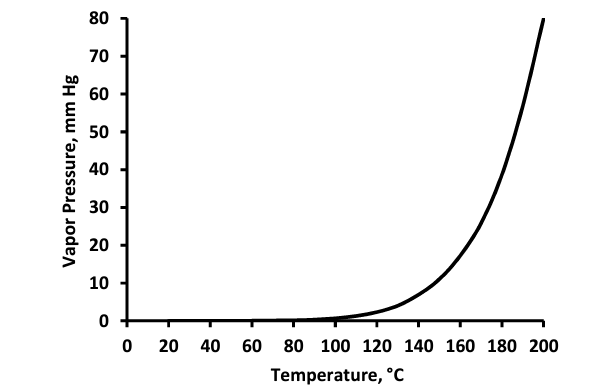

- Vapor Pressure as a Function of Temperature

Safety & Health

- Health Hazards

These anhydrides are primary skin and eye irritants. Avoid contact with skin, eyes, and clothing. Use only with adequate ventilation. In case of contact, follow the procedures outlined in the SDS. Generally, these procedures include immediately flushing the affected skin or eyes with copious amounts of water for at least 15 minutes.

In the case of eye contact, get medical attention. Wash contaminated clothing before reuse. Follow the recommendations in the SDS for personal protective equipment when handling these materials. At a minimum, these procedures typically include protective chemical goggles, impenetrable gloves, and measures to avoid breathing chemical vapors.

Storage & Handling

- Storage

MHHPA-KB will react with water to form methylhexahydrophthalic acid. This is normally undesirable, so MHHPA should be stored in such a way that it is carefully protected from moisture contamination. For more details on the design of bulk storage for MHHPA-KB, consult the Dixie Chemical Company brochure “Epoxy Curing Agent Storage Requirements.”