Knowde Enhanced TDS

Identification & Functionality

- INCI Name

- Cosmetic Ingredients Functions

- CAS No.

- 9004-65-3

- Technologies

- Product Families

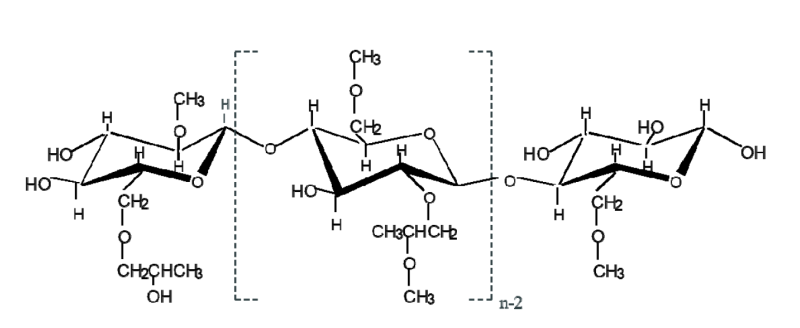

- Chemical Structure

- Synonyms

Methoxy and hydroxypropyl substituted cellulosic polymers

Features & Benefits

- Benefit Claims

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Bath & Shower Applications

- Hair Care Applications

- Personal Hygiene Applications

- Skin Care Applications

- Recommended Applications

- Shampoos

- Body washes

- Hand soaps & bar soaps

- Hair gels & mousses

- Shaving products

- Skin care

- Formulating Tips

- CELLOSIZE™ Texture 40-0100 Hydroxypropyl Methylcellulose is surface treated with glyoxal to render the powders temporarily insoluble in cold water. This allows the CELLOSIZE™ product to be added to a formulation and dispersed at relatively low shear without any significant viscosity increase initially.

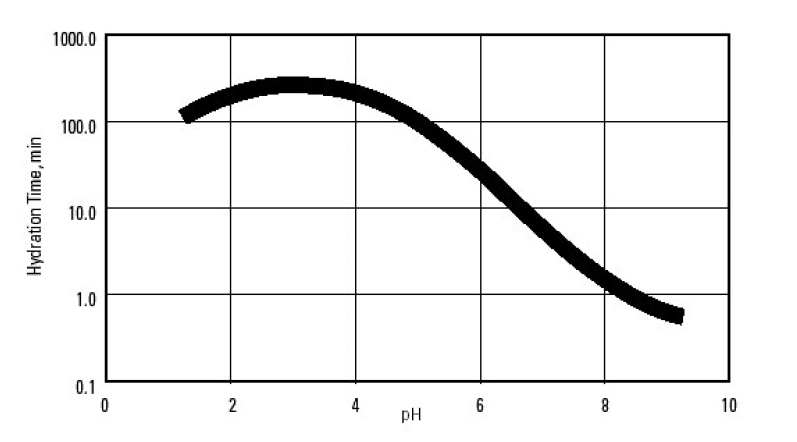

- The “time delay” of the hydration or viscosity build is a function of temperature, pH, and concentration of CELLOSIZE™ Texture. Normally, the concentration of CELLOSIZE™ Texture in the system does not become a factor until the concentration exceeds 5% by weight (relative to water in the system). At higher concentrations, the time of hydration (referred to as delay time) is reduced. The delay time is generally reduced as temperature is raised. The figure below shows a typical delay time as a function of pH, evaluated at room temperature.

Figure 1: Typical hydration delay time of CELLOSIZE™ Texture products as a function

of pH

- In many cases it is desirable to “trigger” viscosity build immediately following dispersion. Aqueous slurries can be held for 45 minutes and still remain usable in neutral systems. A trigger can conveniently be used by adding a small amount of a base, such as ammonium hydroxide, sodium bicarbonate, etc. If CELLOSIZE™ Texture is dispersed in neutral water (pH of 7), there is adequate time for thorough dispersion. Addition of base to raise the pH to approximately 9 causes the hydration to be completed in just a few minutes.

- Common alkaline catalysts used in personal care are dilute sodium hydroxide, alkanolamines, amino methyl propanol (AMP), or any other raw material which would raise pH above 8.0.An excellent catalyst that serves double duty in these formulations is VERSENE™ 100 Chelating Agent (tetrasodium EDTA) which contributes a small but effective amount of alkalinity.

- For best results and to achieve maximum hydration, surface treated CELLOSIZE™ Texture powders should be added with good agitation to a neutral pH system. The system should be agitated thoroughly for a few minutes, followed by an adjustment of pH to 8.5 to 9.0 with continued agitation, until full viscosity is reached (usually 10 to 30 minutes). Once the pH has been shifted to the alkaline side (pH 8.5 to 9.0), allowing full and rapid solubilization of the surface-treated product, solutions are stable over the pH range of 3 to 11.

Dispersion Technique

- Add the cold water dispersible CELLOSIZE™ Texture powder to water at neutral pH. Cold water dispersible products can be added directly to water systems at 40°C or below. Begin agitation.

- Continue agitation and add sufficient base to raise the pH to 8.5–9.0. This will result in rapid viscosity development. Continue agitation until sufficient hydration and full viscosity has been achieved (usually 10–30 minutes).

- Re-adjust pH to desired value for final formulation. Solutions of CELLOSIZE™ Texture are stable at pH 3–11.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Bio-based Carbon Weight | 60 | % | — |

| Hydroxypropyl Content | 28 | % | — |

| Methoxyl Content | 18 | % | — |

| Moisture Content (as packaged) | max. 7.0 | % | DOWM 100667 |

| Particle Size (Through 40, U.S. Standard Sieve) | min. 99 | % | DOWM 100669 |

| Sodium Chloride Content | max. 5.0 | % | DOWM 100187 |

| Viscosity (at 20°C, 2% in water) | 10000 - 16500 | mPa.s | DOWM 101662 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Test Methods for Properties

- This product is not intended for use as a direct food additive or in pharmaceutical applications.

- DOWM - Dow Test Method

- Mechanism of Action

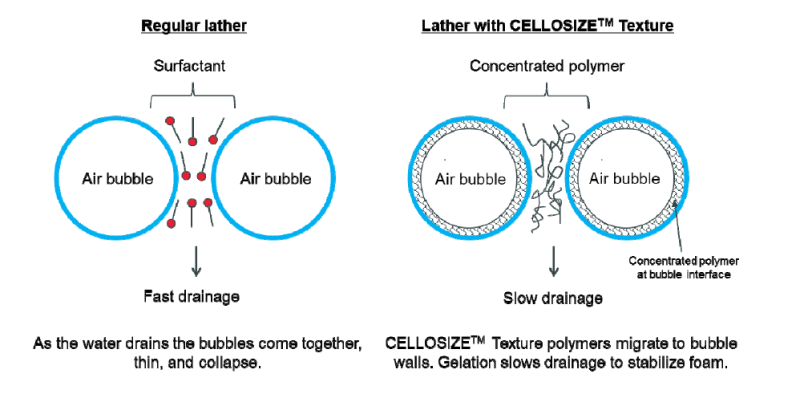

CELLOSIZE™ Texture products offer a unique property called interfacial gelation. This property is the cumulative result of the inherent surface activity and gelling behavior of hydroxypropyl methylcellulose. Interfacial thermal gelation occurs spontaneously even in very dilute systems over a wide range of use temperatures. This formation of gelled films within the foam accounts for the polymer's ability to enhance lather in cleansing products of all types. It also explains why foams are denser and more stable.

Packaging & Availability

- Packaging Type

- Packaging Information

Product is sold in 25 kg bags.

Storage & Handling

- Shelf Life

- 36 months

- Disposal Considerations

- Dispose in accordance with all local, state (provincial) and federal regulations. Empty containers may contain hazardous residues. This material and its container must be disposed in a safe and legal manner.

- It is the user’s responsibility to verify that treatment and disposal procedures comply with local, state (provincial) and federal regulations. Contact your Dow Technical Representative for more information.

- Usable Life and Storage

Shelf life is 36 months. Store the product indoors in a closed container.