Knowde Enhanced TDS

Identification & Functionality

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Attributes

- Satin-like feel

- Cold processing

- Clear appearance

- Ability to create clear systems

- Enhanced sensory profile

- Perceived moisturization

- Perceived smoothness

- Listed in the Catalog of Cosmetic Ingredients Used in China

Applications & Uses

- Markets

- Formulation Tips

DOWSIL(TM) 3901 Liquid Satin Blend into the oil phase of a formulation using simple mixing to help with emulsification or blending with other polar or non-polar oils. There is no need for post-shearing. Formulation with DOWSIL 3901 Liquid Satin Blend can be achieved using cold process.

Formulation Tips

- It may be added to the oil phase or silicone phase in an emulsion formulation.

- It may be post-added to emulsions provided the emulsion is viscous enough for the DOWSIL 3901 Liquid Satin Blend to be dispersed.

- For ease of use, its viscosity may be reduced by blending with dimethicone or other similar non-polar oils.

- It may be necessary to use a syringe or similar device to help weigh out material.

- It may be formulated with organic oils and silicone-based materials with the use of mixers.

- It is dispersible in a variety of liquid oils (refer to Figures 1 and 2)

- Because the polymer is stable, DOWSIL 3901 Liquid Satin Blend may be subjected to heat for a short duration. When heat is used, material should be processed in an enclosed vessel to prevent the dimethicone from volatilizing; the vessel should be inerted at temperatures over 80°C (176°F).

Figure 1: CompatibilityDOWSIL 3901 Liquid Satin Blend: Cosmetic Ingredient

Cosmetic Ingredient (INCI) 10:90 50:50 90:10 Hydrophilics Water NC NC NC Ethanol NC NC NC Esters Isopropyl Myristate C C C Isodecyl Neopentanoate C C C C12-15 Alkyl Benzoate NC NC C Caprylic/Capric Triglyceride NC NC C Vegetable Oil Sunflower Oil NC NC H Castor Oil H H H Sunscreens Ethylhexyl Methoxycinnamate NC NC H Etheylhexyl Salicylate NC H C Octocrylene NC H H Silicones Cylcopentasiloxane C C C PDMS 2 CST C C C PDMS 5 CST C C C PDMS 100 CST C C C PDMS 350 CST C C C Phenyl Trimethicone C C C Caprylyl Methicone C C C Hydrocarbons Isododecane C C C Isohexadecane C C C Mineral Oil NC NC C NC: Not Compatible, H: Hazy, C: Clear

Figure 2: Dissolution TimesSolvent Time needed C11-13 Isoparafin, IDD, IHD, IPM, <20 minutes Cyclopentasiloxane, Phenyl Trimethicone, Caprylyl Methicone XIAMETER™ PMX-200 Silicone Fluid 2 cst, 5 cst, 10 cst XIAMETER™ PMX-200 Silicone Fluid 50 cst, Dicaprylyl Carbonate 20–40 minutes XIAMETER™ PMX-200 Silicone Fluid 100 cst 40–60 minutes XIAMETER™ PMX-200 Silicone Fluid 350 cst 60–80 minutes Ethanol, Caprylic/Capric Triglyceride, C12-15 Alkyl Benzoate Not Compatible Procedure: Mixed 50:50 using a marine propeller at 300 rpm at room temperature.

Properties

- Physical Form

- Appearance

- Clear to translucent, colorless to, light amber, no significant particulate

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (Steady Shear) | 1000 - 8000 | cP | CTM1094 |

| Non Volatile Content (at 2g, 150°C, 3h, Al Cup, Forced Draft) | 6 - 6.5 | % | CTM0208 |

| Cyclotetrasiloxane (D4) Content | max. 0.1 | % | — |

| Cyclopentasiloxane (D5) Content | max. 0.1 | % | — |

| Heavy Metals | max. 20 | ppm | — |

| Arsenic Content | max. 2 | ppm | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Shear Degradation & Dilution Processing

Processing : The following information may be useful when processing DOWSIL 3901 Liquid Satin Blend.

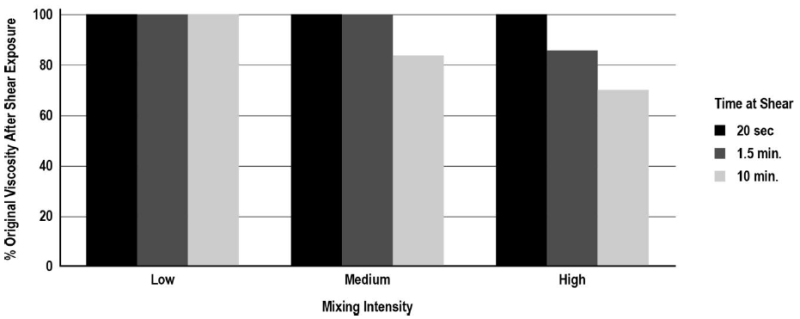

Shear Degradation : The properties of the polymer contained within DOWSIL 3901 Liquid Satin Blend can be degraded when exposed to excessive shear. Figure 3 demonstrates the ability to lower the viscosity of the material under various shear for different time periods. The results are shown as % retention of the original material’s viscosity. As can be noted, under low shear conditions (mixing such as stirring or agitated vessels) the material is stable. However, as you increase the applied shear to a medium rate (low or medium speed dispersers as one example) the material is stable under lower time exposure but can degrade with longer exposure. Under high shear conditions (rotor stators or high speed dispersers) the material can degrade with short exposure. Each situation is different and needs to be assessed as such, so please be aware of this processing limitation when evaluating this material in formulation and when designing processes.

Figure 3: Shear Degradation

DOWSIL™ 3901 Liquid Satin Blend Potential Loss of Properties with Applied Shear

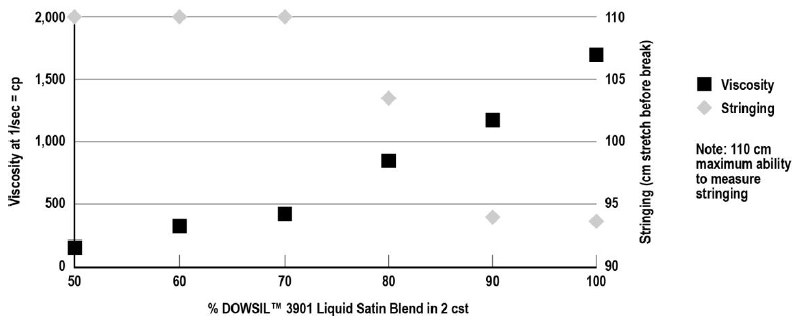

Dilution : DOWSIL 3901 Liquid Satin Blend can retain its properties upon dilution. Figure 4 shows that as you dilute the material in additional dimethicone fluid, the viscosity drops corresponding to the dilution of the polymer as expected. However, the stringing nature of the material actually increases indicating that the polymer entanglements continue thru dilution with additional fluid.

Figure 4: Dilution

DOWSIL™ 3901 Liquid Satin Blend Dilution Curve Batch #5

Clean-up : A non-polar solvent, which dilutes DOWSIL 3901 Liquid Satin Blend, is recommended for soaking or cleaning equipment.

Packaging & Availability

- Packaging Information

- This product is available in 170 kg drums and 16 kg pails.

- Samples are available in 400 ml bottles.

Storage & Handling

- Shelf Life

- 720 Days

- Usable Life & Storage

Stored at or below 40°C (104°F) in the original unopened containers, this product has a usable life of 24 months from the date of production.