Knowde Enhanced TDS

Identification & Functionality

- Ingredient Origin

- Cosmetic Ingredients Functions

- Technologies

- Product Families

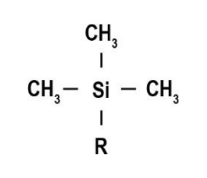

- Chemical Structure

R is Stearoxy

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Features

- Increased viscosity

- Low melting point

- Compatible with organic ingredients

- Lubricity

- Provides water repellent, non-occlusive film

- Detackification

Applications & Uses

- Markets

- Color Cosmetic Applications

- Hair Care Applications

- Skin Care Applications

- Product Applications

- In skin creams it enhances feel and rub out characteristics at use levels from 5 - 10%.

- Detackification is achieved at even lower levels 0.5 - 2%. Payout and feel in lipstick is imparted at use levels from 1 - 5%.

- In non-lather shaving creams lubricity can be markedly improved at use levels of 3 - 5%; for feel the use levels may be as low as 1% or as high as 5%.

- Very low use levels are required to impart soft feel and luster to hair sprays (0.1 - 0.5%), while hydrophobicity of make-up can be controlled quite accurately with use levels in the range of 0.1 to 1%.

- Compatibilities

Type of Material Ethanol (95%) C (hot) Water I Glycerine I I Mineral oil C C Beeswax C C Isopropyl myristate C C Lanolin C C Dimethicone 350mm²s¹ C Paraffin wax C 1. Proportions tested: 1:1, 10:1, 1:10.

C = Compatible, I = Incompatible.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Flash Point | 75.0 | °C | Closed Cup |

| Melting Range | 50 - 55 | °C | — |

| Free Stearyl Alcohol | 35 - 48 | % | Chromatogram 0015 CTM0087 |

| Cyclotetrasiloxane (D4) Content | max. 0.1 | % | — |

| Cyclopentasiloxane (D5) Content | max. 0.1 | % | — |

| Friction and Wear | max. 0.12 | — | — |

| Color (at 60°C) | max. 200 | APHA | — |

Regulatory & Compliance

- Regulatory Status

DOWSILTM 580 Wax is referenced in JCIC under the chemical name Stearoxytrimethyl-

silane with the code 523139 in the CLS categories: 1–7: No limit, 8–11: No limit.

Packaging & Availability

- Packaging Information

- This product is available in 14 kg pails and 160 kg drums.

- Samples are available in 500 ml bottles.

Storage & Handling

- Shelf Life

- 30 months

- Usable Life And Storage

When stored at or below 25°C (77°F) in the original unopened containers, this product has a usable life of 30 months from the date of production.

At temperatures above 40°C (104°F), DOWSILTM 580 Wax will start to melt and separation may occur. This is a physical separation of the product, not a quality or chemistry issue. This is a typical property for this product. To prevent this separation, it is suggested to store the drums in a cool location (< 30°C/< 86°F). If separation does occur, the product should be re-melted to 65 - 70°C (149 - 158°F) and mixed thoroughly to form a homogeneous mixture prior to use.

Once the drum is re-melted, remixed, and cooled to less than < 30°C (< 86°F), the liquid phase will re-solidify. The rate of solidification is dependent upon the cooling temperature. There is no change of product chemistry and properties after this re-melting process.- Handling Precautions

Under elevated temperature conditions, this material can generate hexamethyldisiloxane which is highly flammable. If heating this material, bond and ground and use an inert purge for vessels to prevent a possible fire.