Knowde Enhanced TDS

Identification & Functionality

- Carrier

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

- Composition

Approximately 12.1 wt. percent Dimethicone Crosspolymer in Cyclopentasiloxane (D5)

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Attributes

- Smooth, clear to slightly translucent cross-linked silicone elastomer gel

- Easy to formulate

- Provides dry smoothness and a light, silky, non-greasy skin feel

- Enhances the esthetic of volatile silicones

- No balling effect when rubbed on the skin

- Reduces tackiness of formulations

- Quick absorption

- Cold processing

- Acts as a thickening agent for water-in-oil and water-in-silicone formulations and silicone fluids

- May improve fragrance retention

Applications & Uses

- Markets

- Hair Care Applications

- Sun Care Applications

- Usage

Disperse the oil-phase into DOWSIL™ EL-9048 Silicone Elastomer Blend using simple mixing. There is no need for post-shearing. DOWSIL™ EL-9048 Silicone Elastomer Blend provides cyclopentasiloxane which has already been thickened and can provide a novel form of delivery for other formulation components. Thickening of formulations can be achieved using a cold process.

Formulation Tips

- DOWSIL™ EL-9048 Silicone Elastomer Blend formulated into oil-in water emulsions, water-in-oil emulsions and anhydrous products.

- It can be added to the oil phase or silicone phase in an emulsion formulation.

- It can be post-added to emulsions provided the emulsion is viscous enough for DOWSIL™ EL-9048 Silicone Elastomer Blend.

- For ease of use, its viscosity may be reduced by blending with Dimethicone or Cyclomethicone.

- It may be formulated with organic oils and silicone-based materials with the use of mixers and may be subjected to high shear devices such as homogenizers and sonolators.

- It is dispersible in a variety of liquid oils

- Because the elastomer is stable, DOWSIL™ EL-9048 Silicone Elastomer Blend heat is used, the material should be processed in an enclosed vessel to prevent the Cyclopentasiloxane from volatilizing; the vessel should be inserted at temperatures over 60°C (140°F).

Processing

DOWSIL™ EL-9048 Silicone Elastomer Blend of being a shear-thinning material.

The following information will aid in the selection of the proper equipment to use when processing DOWSIL™ EL-9048 Silicone Elastomer Blend.

Pump Recommendation

GRACO BULLDOG 10:1 Pump with follower plate. Note: GRACO offers various BULLDOG models, and other pump manufacturers may offer similar equipment equally capable of processing the material efficiently. Users should work directly with the pump manufacturer to determine the best design for their needs.

Customer-specific Pump Design Considerations

- Pressure and flow requirements

- Air supply pressure: will depend on plants air supply capabilities.

- Discharge pressure: will depend on total pressure required to move the silicone elastomer blend from point A to point B. Pressure drops due to elevation, frictional losses within the piping, fittings, valves, filters, etc., will need to be considered.

- Flow requirements: will depend on how quickly the user wishes to transfer the silicone elastomer blend from a 208 liter (55 gal) drum into a vessel.

- Material viscosity in cP at the application temperature DOWSIL™ EL-9048 Silicone Elastomer Blend the user to determine the effective viscosity based on the users application. Once the material is pushed through the pump by the follower plate and processed in the pump, the product will shear thin and process as a lower-viscosity fluid.

- Construction material for wetted parts Stainless steel is recommended but carbon steel may also be used.

- Construction materials for seals and gaskets Viton or Teflon materials are recommended.

Clean-up

XIAMETER™ PMX-0245 Cyclopentasiloxane, which dilutes the viscosity DOWSIL™ EL-9048 Silicone Elastomer Blend or cleaning equipment. Other non-polar solvents may work as well.

Properties

- Physical Form

- Appearance

- Clear to translucent colorless to light amber no significant particulate

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (Spindle 94, at 2.5 rpm, Helipath RV TD) | 350000 - 550000 | °C | Corporate Test Method 0050 |

| Specific Gravity | 0.94 | — | — |

| Cyclotetrasiloxane (D4) Content | max. 0.1 | % | — |

| Non Volatile Content (2g, at 150°C, 3h, Al Cup, forced draft) | 12.00 - 12.75 | % | Corporate Test Method 0208 |

| D4 Content | max. 0.1 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

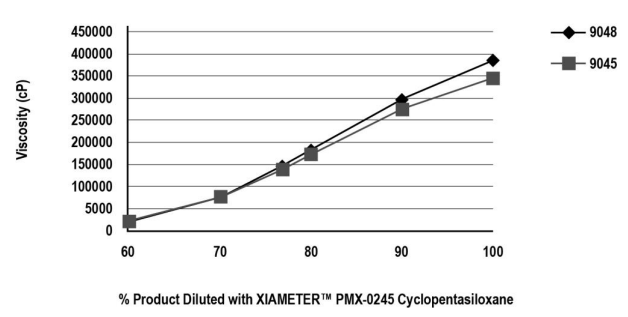

Dilution curves DOWSIL™ EL-9048 Silicone Elastomer Blend and DOWSIL™ 9045 Silicone Elastomer Blend.

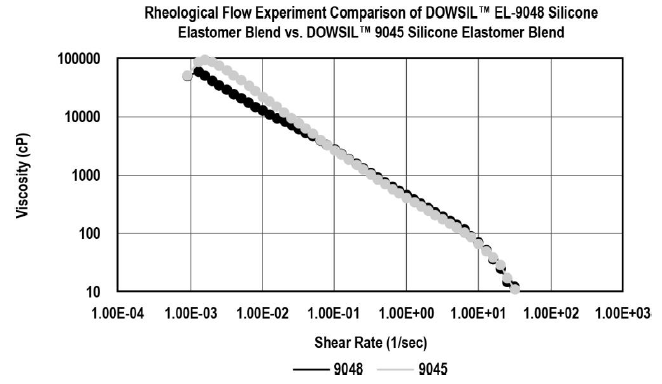

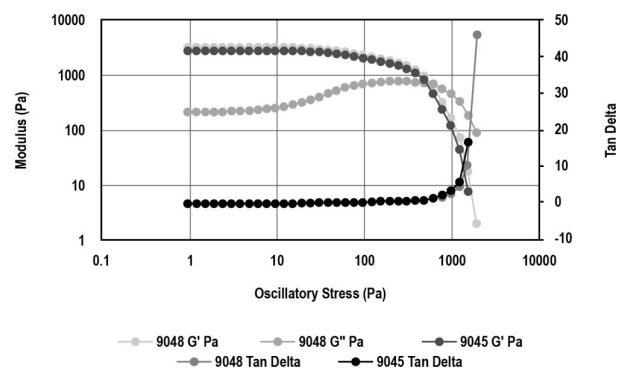

Rheology profile comparison of DOWSIL™ EL-9048 Silicone Elastomer Blend and DOWSIL™ 9045 Silicone Elastomer Blend

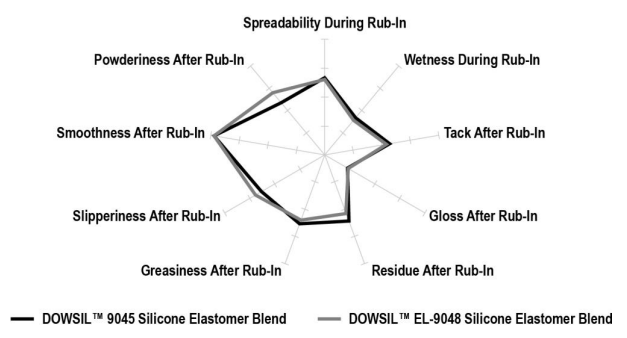

Neat DOWSIL™ EL-9048 Silicone Elastomer Blend has been compared to neat DOWSIL™ 9045 Silicone Elastomer Blend using multiple paired comparison sensory evaluation using 22 experienced panelists. No significant differences were found when comparing the materials for gloss, film residue, greasiness, slipperiness, smoothness, and powdery feel, spreadability, wetness, and tack.

Packaging & Availability

- Packaging Information

This product is available in 15 kg pails and 180 kg drums. Samples are available in 0.4 kg cans.

Storage & Handling

- Shelf Life

- 24 Months

- Usable Life and Storage

When stored at or below 60°C (140°F) in the original unopened containers, these products have a usable life of 24 months from the date of production. DOWSIL™ EL-9048 Silicone Elastomer Blend, and a flammable solid for transportation purposes.