Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Product Highlights

The static charge occurring during

- Pouring off polymer granules.

- Rolling off / up film.

- Piling up sheets.

- Packing up small parts in bigger units.

Static charge shows the following effects

- Granules stick to walls, conveying devices etc.

- Film/sheets stick together.

- Parts cannot be packed because of repulsion.

- Dust attraction during storage.

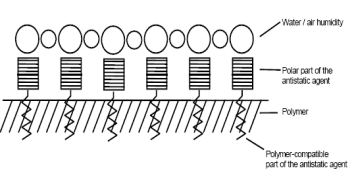

Antistatic MB works by migrating to the surface of the polymer, usually in a molecular or multi-molecular layer and attracting water molecules from the atmosphere. The water lowers the surface resistivity of polymers. Antistatic Masterbatch consists of a hydrophobic part, which confers a level of compatibility with the polymer and a hydrophilic part which attracts the water that forms the surface conductive path.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application

Injection molding.

Properties

- Physical Form

Technical Details & Test Data

- Technical Details