Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Characteristics

The 2K Range of coatings can be applied using selective coating machines such as PVA using the specially adapted part VPX-2KS and Nordson Asymtek using the latest in the AM range.

It displays enhanced thermal performance compared to other 2K products, with an operating range of -65 to +150°C while still offering good chemical resistance.

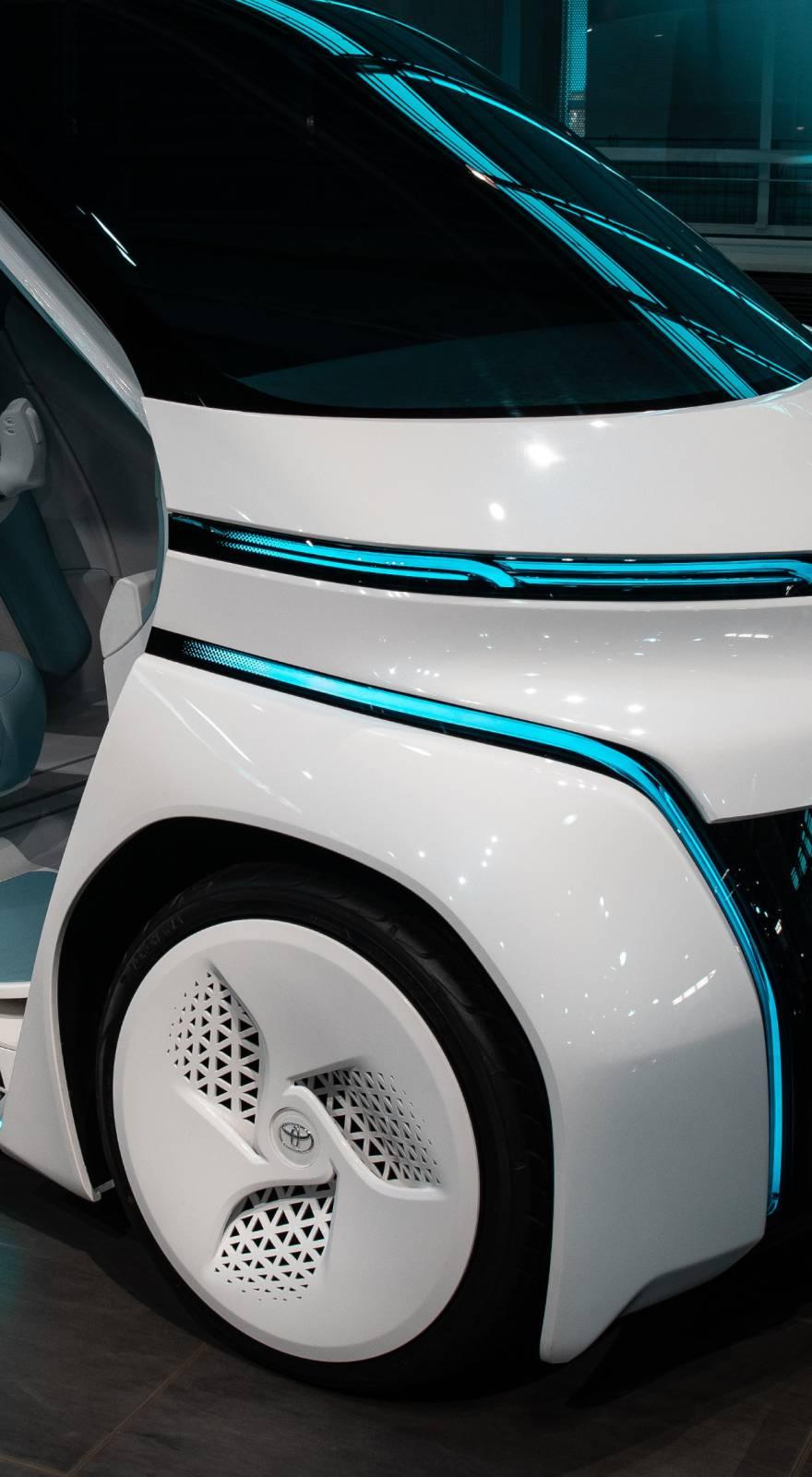

As with the other 2K range of conformal coatings 2K350 is a hydrophobic coating which gives excellent water and moisture protection including salt mists making it an excellent choice for automotive electronics as well as other tough outdoor applications. Read our Article on comparisons verses traditional coatings for more info.

2K300 is available in bulk, however we have also developed a unique sample kit for the prototyping and validation process, eliminating the need for specialist machine equipment or machine down time.

*Two Part System requires 2K300 as Part A and 2KPB0 as reaction agent, please refer to the product TDS for recommended mix ratios.

- Key properties

- Two-part conformal coating

- Unique Sample-Kit available

- Enhanced operating temperature range

- Highly flexible coating, low stress on components

- Hydrophobic; demonstrates excellent water-immersion, salt mist and condensation resistance

- Good solvent resistance

- Excellent coverage, even over difficult geometries

- Meets requirements of IPC-CC-830C, MIL-I-46058C, IEC 61086

- Meets BMW Group Standard requirement GS95011-5

- REACH Compliant & RoHS Compliant

Applications & Uses

- Applications

- Application Method

- Coating Type

Regulatory & Compliance

- Certifications & Compliance