Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Benefits

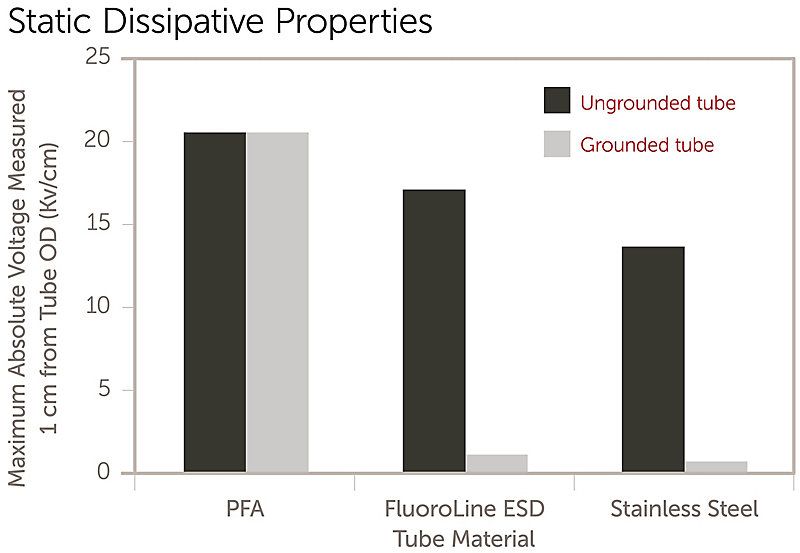

- Extruded stripe on outside of ESD tubing provides a grounding for electrostatic charge buildup in tubing

- The PFA wetted material is 100% virgin grade and provides the lowest extractable ionic and organic levels

- High-purity tubing comes in various standard sizes from 1/8” to 2”

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- FluoroLine® Electrostatic Dissipative (ESD) Tubing Applications

- Flammable chemistries such as solvents

- High-purity, corrosive chemical handling

- Solar, LED, flat panel display

- Excellent performance with low surface tension chemistries

Semiconductor applications :

- Photolithography

- Bulk chemical delivery

- CMP

- Wet etch and clean

- High-temperature cleaning processes

- FluoroLine ESD Tubing Materials of Construction

Wetted : 100% virgin PFA 451 HP resin

Nonwetted : Conductive carbon-loaded PFA- Grounding Strap Materials of Construction

Carbon-loaded polypropylene

Properties

- Physical Form

- Typical Properties

- Grounding Strap Dimensions

- 1/8" to 1" : 210 mm H x 9 mm W x 5.5 mm L (8.27" H x 0.35" W x 0.22" L)

- 1 1/4" to 2" : 256 mm H x 9 mm W x 5.5 mm L (10.07" H x 0.35" W x 0.22" L)

- Connector : 99 mm H x 9 mm W x 5.05 mm L (3.9" H x 0.35" W x 0.2" L)

| Value | Units | Test Method / Conditions | |

| Surface resistivity: | 1 x 10⁵⁻⁶ | Ohm/sq | - |

Regulatory & Compliance

- Approvals

FluoroLine ESD Tube is approved by TUV

Tested according to:- ANSI/ESD S20.20:2014

- ANSI/ESD S1.1:2006

- EN-ISO 4413:2010

Technical Details & Test Data

- Specifications

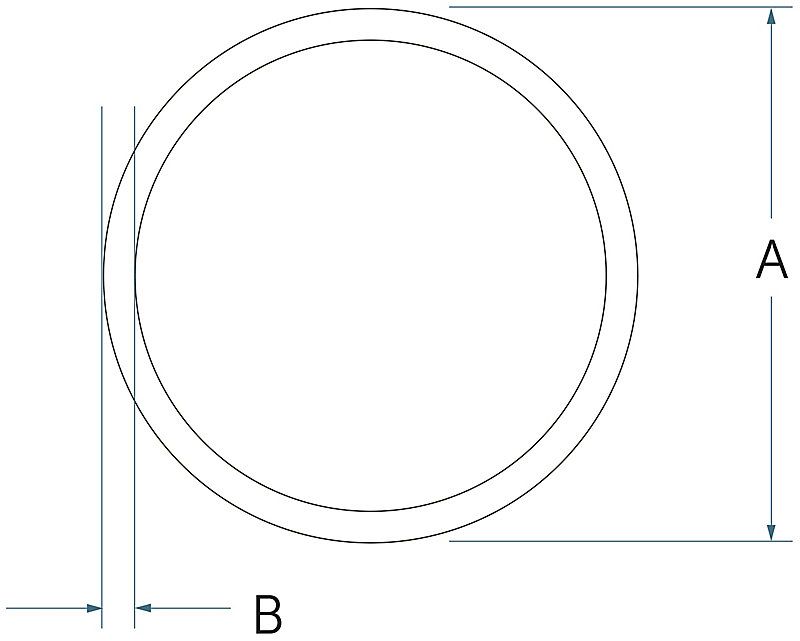

Size Outside Diameter (A) Wall Thickness (B) Outside Diameter Tolerance Wall Thickness Tolerance Minimum Bend Radius1/8" 0.125" (3.18 mm) 0.020" (0.5080 mm) ±0.003" (±0.08 mm) ±0.004" (±0.10 mm) 0.5" (13 mm) 1/4" 0.250" (6.35 mm) 0.047" (1.194 mm) ±0.004" (±0.102 mm) ±0.004" (±0.10 mm) 1.5" (38 mm) 3/8" 0.375" (9.52 mm) 0.062" (1.575 mm) ±0.004" (±0.102 mm) ±0.005" (±0.127 mm) 2.0" (51 mm) 1/2" 0.500" (12.70 mm) 0.062" (1.575 mm) ±0.005" (±0.127 mm) ±0.005" (±0.127 mm) 2.3" (58 mm) 3/4" 0.750" (19.05 mm) 0.062" (1.575 mm) ±0.005" (±0.127 mm) ±0.005" (±0.127 mm) 9.0" (229 mm) 1" 1.000" (25.40 mm) 0.062" (1.575 mm) ±0.005" (±0.127 mm) ±0.005" (±0.127 mm) 11.0" (279 mm) 1 1/4" 1.250" (31.75 mm) 0.075" (1.905 mm) ±0.008" (±0.203 mm) ±0.005" (±0.127 mm) 12.5" (318 mm) 1 1/2" 1.500" (38.10 mm) 0.086" (2.184 mm) ±0.008" (±0.203 mm) ±0.005" (±0.127 mm) 22.5" (572 mm) 2" 2.000" (50.80 mm) 0.090" (2.286 mm) ±0.009" (±0.250 mm) ±0.008" (±0.203 mm) 25.0" (635 mm) - Drawings

- Performance Data

Packaging & Availability

- Sizes available

1/8 - 2"