Esschem

About Us

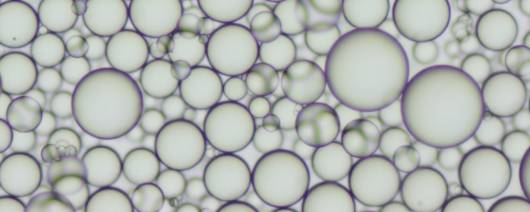

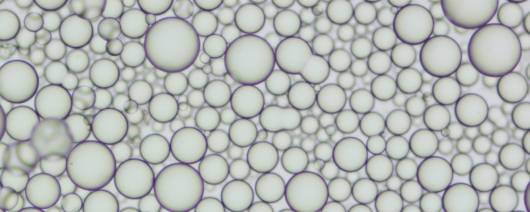

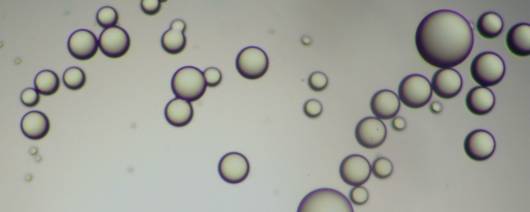

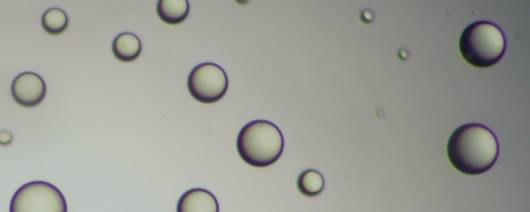

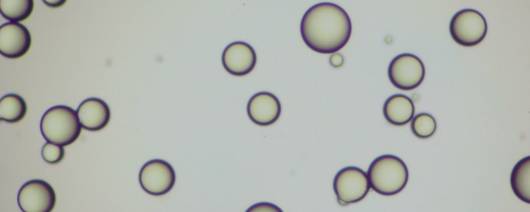

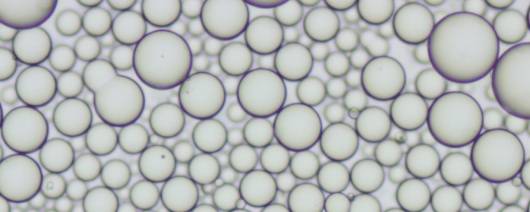

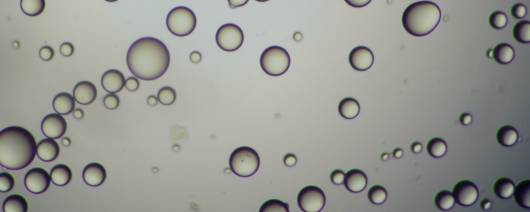

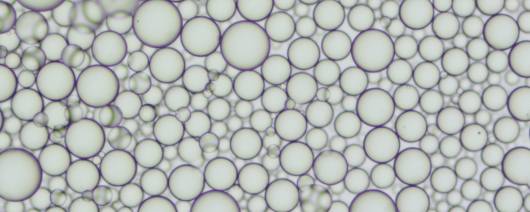

Methacrylate bead polymers & copolymers

Esschem is the world’s leading producer of methacrylic bead polymers.

Today, Esschem continues at the forefront of methacrylate chemistries for orthodontics, cosmetics, orthopedic, and other related industries . We have dedicated ourselves to designing and developing products, services and production capabilities that provide a clear performance difference to our customers.

Our considerable experience makes us a trusted partner and supplier worldwide. Esschem offers a complete set of research, customization, manufacturing and packaging resources to our customers and the industry.

Browse Products by Market

View All ProductsBrowse Products by Technology

View All Products

Featured Products

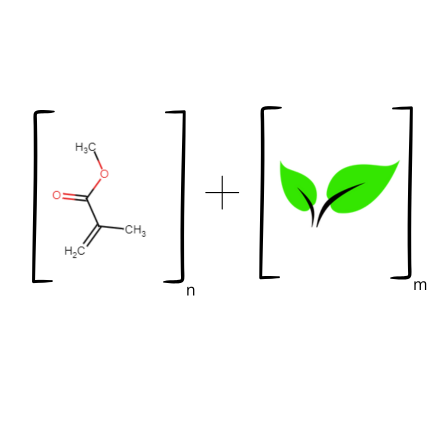

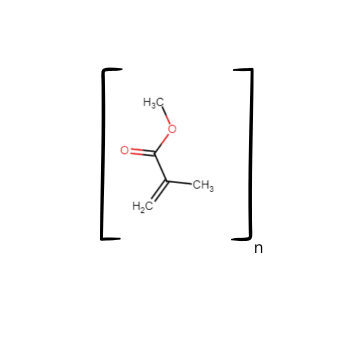

Esschem Bio-plasticized / MMA Bead Polymers

MMA bead polymers containing bio-plasticizers result in materials with increased flexibility and decreased tG.

Applications: Film & Foil Coatings, Roof Coatings, Electronics Adhesives, Printed Circuit Boards (PCBs), Nail Care, Sealants & Caulks, Textile Manufacturing, Carpet & Upholstery, Apparel, Carpet, Medical Devices & Assemblies, Building & Construction, Industrial & Assembly Adhesives, Parts & Components, Medical, Packaging Coatings, Beauty & Care, Decorative Materials & Finishes, Leather & Textiles

Product Families: Visual Modifiers, Texturizers & Fillers, Performance Additives, Thermoset Resins, Binders, Acrylics, Acrylates & Methacrylates, Pre-Treatment Auxiliaries, Acrylics, Resins & Binders, Polymers & Resins, Functionals, Elastomer Additives, Monomers & Oligomers, Battery & Electronic Materials, Textile & Leather Chemicals

Chemical Family: Methacrylates, Acrylic Ester Copolymer, Acrylics, Acrylates & Methacrylates

Polymer Name: Polymethyl Methacrylate (PMMA)

End Uses: Carpet, Medical Devices

Labeling Claims: Biocompatible, Non-Toxic, Bio-based

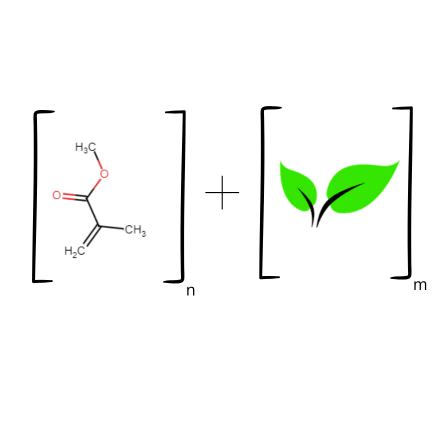

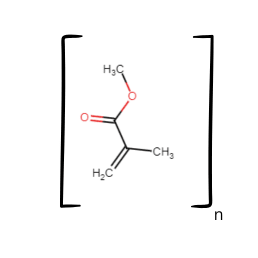

Esschem MMA Bead Copolymers

Methyl methacrylate (MMA) bead polymers are known for high glass transition temperature, melting point, tensile strength, and impact strength.

Applications: Chemical Manufacturing, Glazing & Window Elements, Siding & Trim, Film & Foil Coatings, Roof Coatings, Electronics Adhesives, Printed Circuit Boards (PCBs), Nail Care, Sealants & Caulks, Additive Manufacturing, Textile Manufacturing, Carpet & Upholstery, Apparel, Carpet, Medical Devices & Assemblies, Building & Construction, Industrial & Assembly Adhesives, Building Materials, Parts & Components, Medical, Chemical & Industrial Manufacturing, Packaging Coatings, Beauty & Care, Building Envelope & Roofing, Decorative Materials & Finishes, Leather & Textiles

Product Families: Cement & Concrete Additives, Visual Modifiers, Texturizers & Fillers, Performance Additives, Thermoset Resins, Binders, Acrylics, Acrylates & Methacrylates, Pre-Treatment Auxiliaries, Acrylics, Resins & Binders, Polymers & Resins, Functionals, Elastomer Additives, Monomers & Oligomers, Construction Chemicals, Battery & Electronic Materials, Textile & Leather Chemicals

Chemical Family: Methacrylates, Acrylic Ester Copolymer, Acrylics, Acrylates & Methacrylates

Polymer Name: Methyl Methacrylate Copolymer

End Uses: Electrical/Electronic Applications, Prototyping, 3D Printing Resins, Carpet, Medical Devices

Labeling Claims: Biocompatible, Non-Toxic

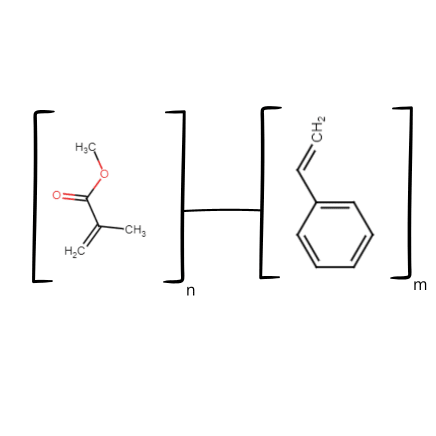

Esschem MMA - Styrene Bead Copolymers

MMA / Styrene bead copolymers, also known as SMMA, is a clear thermoplastic, with high transparency, high rigidity and excellent scratch resistance.

Applications: Film & Foil Coatings, Roof Coatings, Electronics Adhesives, Printed Circuit Boards (PCBs), Nail Care, Sealants & Caulks, Textile Manufacturing, Apparel, Carpet, Medical Devices & Assemblies, Building & Construction, Industrial & Assembly Adhesives, Parts & Components, Medical, Packaging Coatings, Beauty & Care, Decorative Materials & Finishes, Leather & Textiles

Product Families: Visual Modifiers, Texturizers & Fillers, Performance Additives, Thermoset Resins, Binders, Acrylics, Acrylates & Methacrylates, Pre-Treatment Auxiliaries, Acrylics, Resins & Binders, Polymers & Resins, Functionals, Elastomer Additives, Monomers & Oligomers, Battery & Electronic Materials, Textile & Leather Chemicals

Chemical Family: Styrene-Acrylic Copolymer, Styrenics, Styrene Copolymers, Methacrylates, Styrene Methacrylate Copolymer, Acrylics, Acrylates & Methacrylates

Polymer Name: Styrene Methyl Methacrylate Copolymer (SMMA)

End Uses: Carpet, Medical Devices

Labeling Claims: Biocompatible, Non-Toxic

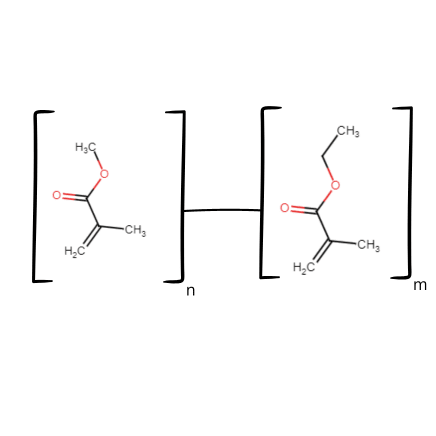

Esschem MMA - EMA Bead Copolymers

Bead copolymers of MMA / EMA usually exhibit high glass transition temperatures, melting points, and tensile strengths.

Applications: Film & Foil Coatings, Roof Coatings, Electronics Adhesives, Printed Circuit Boards (PCBs), Nail Care, Sealants & Caulks, Textile Manufacturing, Carpet & Upholstery, Carpet, Medical Devices & Assemblies, Building & Construction, Industrial & Assembly Adhesives, Parts & Components, Medical, Packaging Coatings, Beauty & Care, Decorative Materials & Finishes, Leather & Textiles

Product Families: Visual Modifiers, Texturizers & Fillers, Performance Additives, Thermoset Resins, Acrylics, Acrylates & Methacrylates, Pre-Treatment Auxiliaries, Acrylics, Binders, Resins & Binders, Polymers & Resins, Functionals, Elastomer Additives, Monomers & Oligomers, Battery & Electronic Materials, Textile & Leather Chemicals

Chemical Family: Methacrylates, Acrylic Ester Copolymer, Acrylics, Acrylates & Methacrylates

Polymer Name: MMA/EMA Copolymer

End Uses: Carpet, Medical Devices

Labeling Claims: Biocompatible, Non-Toxic

Esschem EMA Bead Copolymers

EMA bead polymers provide the strength of PMMA, with a slightly lower glass transition, and an overall slightly softer and more flexible final product.

Applications: Film & Foil Coatings, Roof Coatings, Electronics Adhesives, Printed Circuit Boards (PCBs), Nail Care, Sealants & Caulks, Textile Manufacturing, Carpet & Upholstery, Apparel, Carpet, Medical Devices & Assemblies, Building & Construction, Industrial & Assembly Adhesives, Parts & Components, Medical, Packaging Coatings, Beauty & Care, Decorative Materials & Finishes, Leather & Textiles

Product Families: Visual Modifiers, Texturizers & Fillers, Performance Additives, Thermoset Resins, Binders, Acrylics, Acrylates & Methacrylates, Pre-Treatment Auxiliaries, Acrylics, Resins & Binders, Polymers & Resins, Functionals, Elastomer Additives, Monomers & Oligomers, Battery & Electronic Materials, Textile & Leather Chemicals

Chemical Family: Methacrylates, Acrylic Ester Copolymer, Acrylics, Acrylates & Methacrylates

Polymer Name: Ethyl Methacrylate Copolymer

End Uses: Carpet, Medical Devices

Labeling Claims: Biocompatible, Non-Toxic

Most Viewed Products

View All Products