Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- KEY FEATURES

• ESD safe

• Flexible

• Best-in-class tensile strength

• Exceptional elongation at break

• Excellent abrasion, tear and wear resistance

• High impact

• Excellent vibration damping

• Low temperature flexibility

• Excellent chemical, solvent, oil and ozone resistance

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- APPLICATIONS INCLUDE

• Electronics manufacturing ESD safe jigs and fixtures

• Vibration dampening feet

• Grommets

• Bushings

• Protective case inserts

• Automotive vibration isolation

• Overmolded soft grips

• Flexible hose and ducting

Properties

- Physical Form

- Material Specific Properties

| Value | Units | Test Method / Conditions | |

| Abrasion Loss | 25 | mm3 | ISO 4649 |

| Hardness | 95 | Shore A | ISO 868 |

| Compression (70˚C) | 45 | — | ISO 815 |

| Compression RT | 30 | — | ISO 815 |

| Specific Gravity | 1.15 | g/cm3 | ISO 1183 |

| Surface Resistance | 10^6 – 10^8 | Ohms | ANSI/ESD STM11.11 |

| Tear Strength | 100 | kN/m | ISO 34-1 |

Regulatory & Compliance

- PRINT PARAMETERS

Nozzle Temperature, ºC 240 Bed Temperature, ºC 80 Print Speed, mm/s 40 Layer Height, mm 0.35 Ex. Multiplier (Flow) 1.05 Fan Speed, % 0 Machine Ultimaker 3 Nozzle Size, mm 0.8

Technical Details & Test Data

- RECOMMENDED PRINT SETTINGS

Nozzle Temperature, ºC 230 – 250 Bed Temperature, ºC 50 – 80 Print Speed, mm/s 20 – 40 First Layer Speed, mm/s 15 – 20 Ex. Multiplier (Flow) 1.05 Fan Speed, % 0 – 20 Bed Material Glass Bed Adhesion Method Dimafix® - Test Data

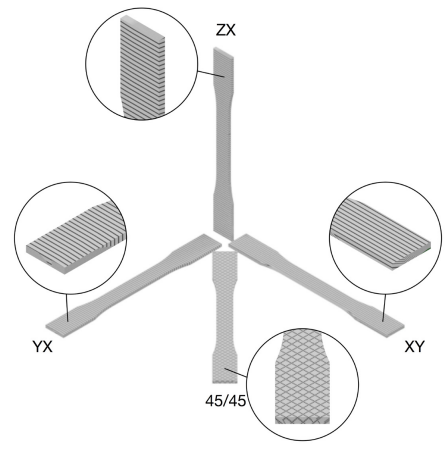

Parts printed in three major axes and common infill patterns

YX: Traces aligned perpendicular to major length

ZX: Traces aligned orthogonal to major length

XY: Traces aligned parallel to major length

45/45: Common Infill: +-45, 2 outlines- MECHANICAL PROPERTIES

Property Test Method Print Orientation XY YX ZX Tensile Strength, MPa ASTM D638 34 22 7 Elongation at Break, % ASTM D638 639 435 48