Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

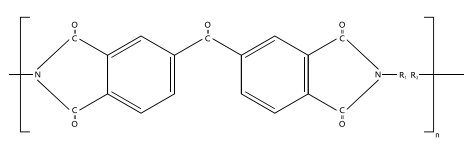

- Chemical Structure

The P84® fibre is a polyimide based fibre with a typical textile character. Polyimides are known to be used in a wide range of operating temperatures starting from cryogenic applications and ending with high temperature applications at the limits of polymer based materials.

The thermal stability is based on the aromatic backbone of the polymer. The fibres do not melt. Despite their halogen free structure they exhibit a high LOI of 38 %, which means the P84® fibres are classified as non flammable.

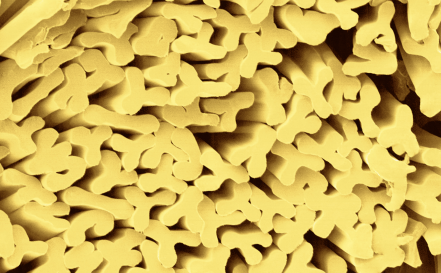

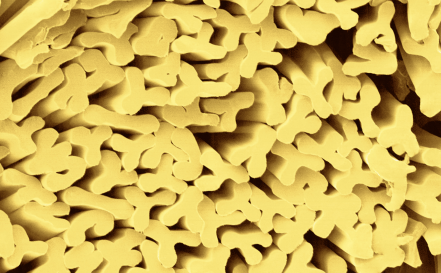

P84® fibres have a rather unique cross section offering the highest specific surface of all available standard textile fibres.

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Cross Section of P84® Fibres

The unique multilobal cross section offers up to 90% more surface area compared to conventional round fibres and is the key advantage of P84®. This increased surface area results in the highest filtration efficiency of conventional fibres, even for sub micron particles. The fibres meet the requirements of all common textile processing steps. Besides standard grades, micro denierfibres are part of the production range.

- Product Characteristics

The innovative P84® HT fibre is a non- melting polyimide based fibre with an exceptional thermal stability, based on the unique multilobal cross section & the aromatic backbone of the polymer. Additionally, with a remarkable LOI of 38%, these halogen-free fibres are classified as non-flammable, making them the perfect choice for applications where safety is a top priority. P84® HT’s unique shape makes it possible for your next-to-skin protective clothing to assure full-battle protection by providing an excellent barrier layer that fends off those harmful particles while maximizing air flow at the same time.

P84® HT multilobal shape- Unique irregular cross section for excellent thermal insulation

- Soft-touch

- Non-melting

Applications & Uses

- Markets

- Applicable Processes

- Industrial Additives End Use

Properties

- Typical Properties

- Product Properties

Concentration [%] Temp. [°C/°F] Time [hrs.] Effect on tenacity

Chemicals Sulphuric acid 10 20/68 100 no Nitric acid 10 20/68 100 no Hydrochloric acid 20 50/122 24 minimal Hydrobromic acid 37 20/68 100 no Hydrofluoric acid 40 20/68 100 no Acetone 100 20/68 1000 no Benzene 100 20/68 1000 no Perchloroethylene 100 70/158 168 no no = 0 to 15 % Loss in tenacity, minimal = 16 to 30 % Loss in tenacity

P84® provides good chemical stability to all common solvents, such as alcohols, ketones, chlorinated hydrocarbons and a wide range of other chemicals. It also offers high resistance to fats, oil and fuel. In addition, P84® fibres have a proven record of good resistance in a broad range of the pH-scale.- Notes

Test Methods: (1) ASTM D 2259-02 (2016), (2) ASTM F1939-08, (3) ASTM D6413/ D6413M-15, (4) NFPA 1971-2018, par. 8.10

| Value | Units | Test Method / Conditions | |

| Tenacity (dry) | 38 | cN/tex | — |

| Elongation | 30 | % | — |

| Shrinkage (240°C, 15 Min.) | max. 3 % | — | — |

| Density | 1.41 | g/cm³ | — |

| Limiting Oxygen Index | 38 | % | — |

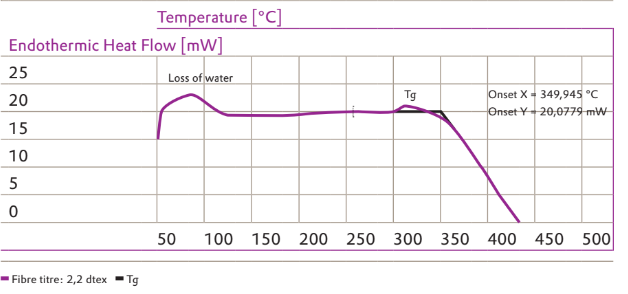

| Glass Transition Temperature | 315 | °C | — |

| Moisture Gain (at 20°C, 60 % Rel. Hum.) | 3 | % | — |

| Radiant Heat Resistance² | 1493 | kJ/m² | — |

| Afterflame³ | 0.5 sec | — | — |

| Afterglow³ | 0.6 sec | — | — |

| Char Length³ | 24 mm | — | — |

| Before Washing & Drying | 15.2 | sec | — |

| After Washing & Drying | 17.3 | sec | — |

Technical Details & Test Data

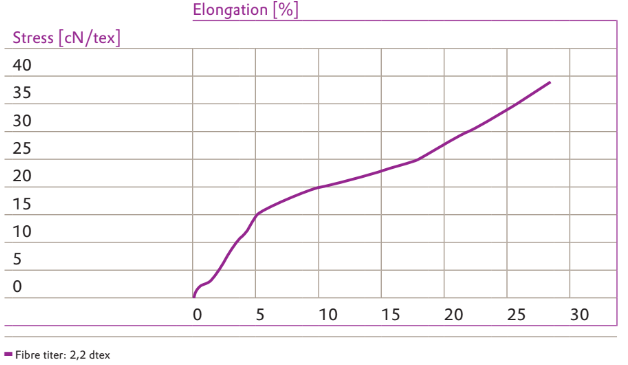

- P84® Stress/Elongation Behaviour

As P84® fibres show a typical textile character the fibre can be processed on standard carding and needling equipment. According to the data, which show a low modulus and a relatively high elongation, P84® is very well suited for textile applications and can be processed using standard textile equipment. The irregular lobed cross section and the crimp are responsible for the bulkiness and the volume of the fibre.

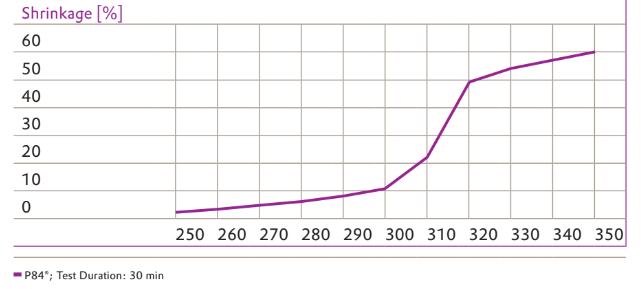

- P84® Fibre Shrinkage Characteristics

During the manufacturing process, the fibres are stretched and the polymer molecules are getting oriented to a certain extent. When exposing the fibres to temperatures near the glass transition temperatures, a reorientation of the molecules takes place and the fibres shrink. The diagram shows the significant increase of the shrinkage after 30 minutes exposure at 315°C (599 °F) and beyond.

- Specific Surface Area

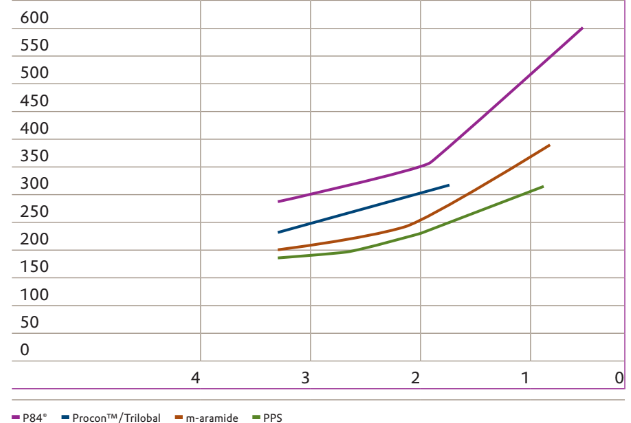

Specific Surface of Different Fibre Materials as Function of the Fibre Fineness

The large surface area primarily depends on the cross section and the fibre titer (fineness). All other fibres with same titer do not meet the specific surface area values of P84®.- P84® Fibre Moisture Gain (at 20°C)

The unique multilobal cross section offers up to 90% more surface area compared to conventional round fibers and is the key advantage of P84®. This increased surface area results in the highest filtration efficiency of conventional fibers, even for sub micron particles. The fibers meet the requirements of all common textile processing steps. Besides standard grades, micro denierfibers are part of the production range.

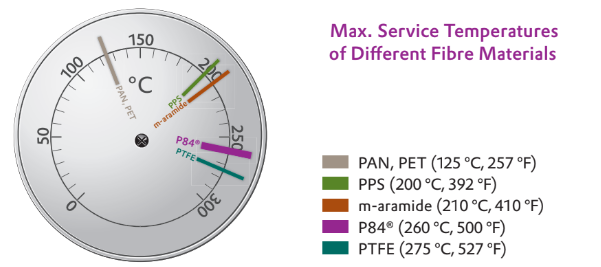

- Service Temperatures

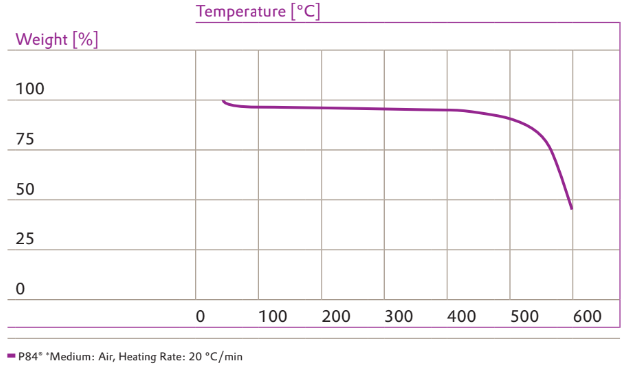

The acceptable average temperature depends on the environment and can be significantly lower than the maximum service temperature. The aromatic backbone ensures temperature stability over a wide range of operating conditions. The peak temperature for the P84® fibre is limited to 260 °C. This is well below the glass transition temperature of 315 °C. Chemical decomposition starts beyond 450 °C without formation of reasonable amounts of harmful substances. The acceptable average temperature in the actual application is depending on the composition of the environment and the expected service life.- Short Term Temperature Stability of P84®

When exposed to high temperatures, P84® degrades the same way as many other organic polymers, leaving a carbon structure. However, the decomposition temperature is extremely high, as shown in the diagram.

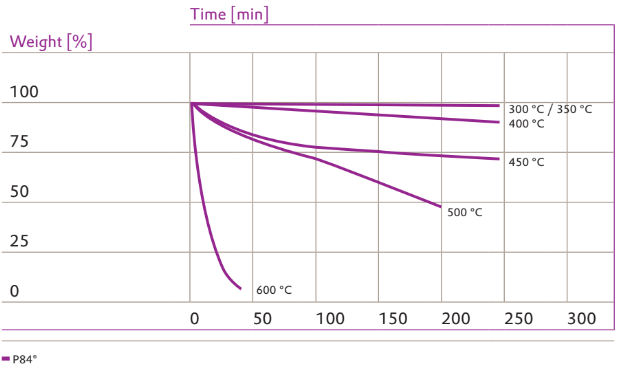

- P84® Fibre Isothermal Weight Loss

The weight loss of P84® is recorded versus time at different temperatures. Up to a temperature of 350°C (662°F) the weight loss is below 3 % and corresponds to the moisture content of the fibre

- Differential Scanning Calorimetry (DSC) - Diagram of P84® in Air

This diagram shows, whether a material consumes or generates thermal energy during a defined temperature program. Especially changes of the structure and melting temperatures can be detected by using this method. P84® has no peaks indicating crystalline regions or melting behaviour, only a glass transition temperature is observed.

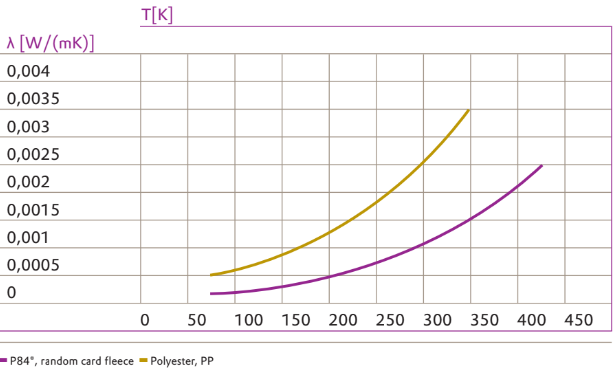

- Thermal Conductivity

The very low thermal conductivity of P84® fibres is used to design fleece constructions for insulating cryogenic processes.

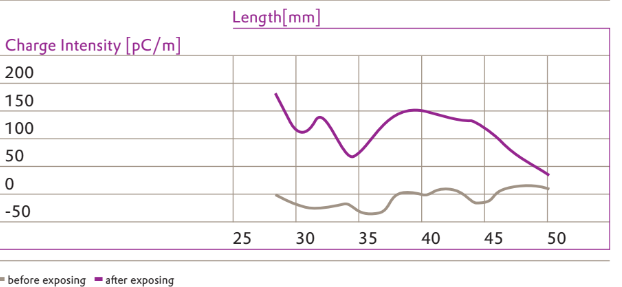

- Electric Charge of P84® Fibres

The diagram schows the electric charge along the length of a P84® fibre before and after exposing to an electric field using a corona charge of 20 kV. All fibres do have either positive or negative charges due to functional groups of the polymer and electrostatic excess charges.

- Oxidative Aging

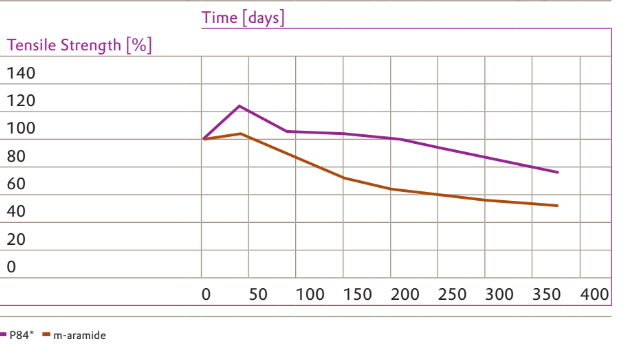

Loss of Tensile Strength of Needle Felts due to Oxidative Aging

Fibres exposed to air at high temperatures are deteriorated by oxygen. The experimental results shown in the chart were carried out at 210 °C (410 °F) and show superior performance of P84® compared to m-aramides.

- Hydrolysis Stability

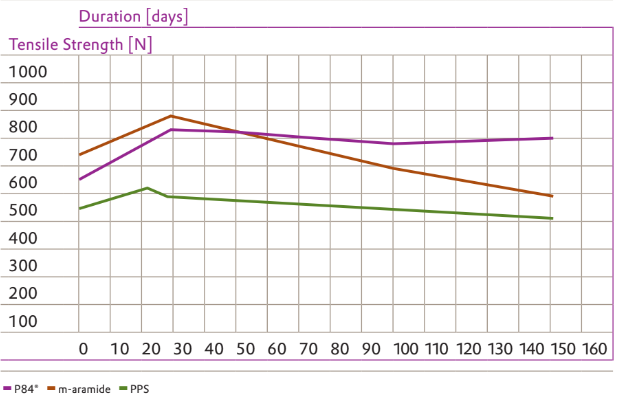

Hydrolysis Stability of Filter Fabrics at 50 vol% Moisture, 170°C

Even under extremely high moisture contents, P84® outperforms many of its competitors, being available for high temperature filtration applications.- Limiting Oxygen Index (LOI) of Fibres

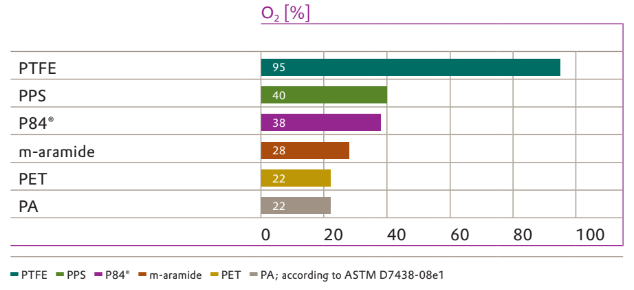

The LOI indicates the level of oxygen needed to keep the material burning after ignition. P84® is classified as non flammable in atmospheric conditions.

- Emission of Toxic Gases during Degradation

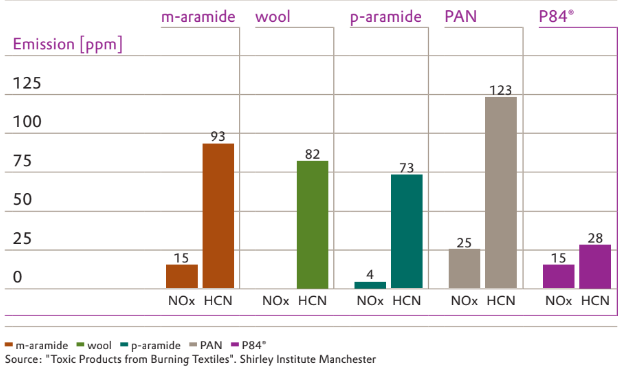

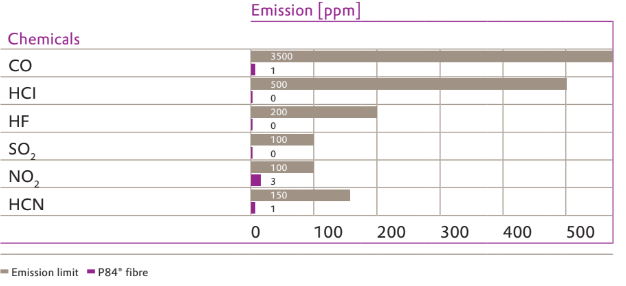

Emission of Toxic Gases during the Degradation of Fibres

Gas volume and gas composition are strongly depending on conditions like excess or shortage of oxygen. Under the chosen conditions, P84® fibres show the lowest generation of toxic HCN (cyanic acid).- Toxic Emissions

Toxic Emissions acc. to ATS 1000.001 or BSS 7239

According to ATS 1000.001 which limits the toxic emissions for aircraft interior, P84® shows excellent performance.

Packaging & Availability

- Product Availability

Staple Fibre

Available Types: 0.6, 1.0, 1.7, 2.2, 3.3, 5.5 and 8.0 dtex

Cut Lengths (Standards): 53, 60, 80 mm

Special Cut Lengths: 2,5-120 mm

Bales: 150 kg and 200 kg

Filament Yarn

Available Type: 1060 dtex, 480 single threads

Twist: 80 t/m

Packaging: 12 cones, 3,5 kg each