Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Benefits

- Tested safety according to ZTV-LSW06/EN 14388

- Anti-graffiti Test according to NF F 31-112

- Bird-friendly (according to ONR 191040)

- Good fire rating

- Vandalism

The sheets offer protection against involuntary breakage and wilfull destruction. The sheets are virtually unbreakable and do not splinter.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

Exolon® Silent Sound can be used for noise protection barriers on motorways with heavy traffic, dual carriageways and railways. Incapseling of machinery, transfo’s and high voltage cables along tracks.

Properties

- Color

- Physical Form

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Charpy Impact Strength (23°C, 3 mm, Notched) | 80P | kg/m² | ISO 179-1eA |

| Charpy Impact Strength (23°C, Unnotched) | non-break | kg/m² | ISO 179-1eU |

| Flexural Modulus (2 mm/min) | 2350.0 | MPa | ISO 178 |

| Flexural Strength (2 mm/min) | min. 90 | MPa | ISO 178 |

| Izod Impact Strength (23°C, 3.2 mm, Notched) | 70P | kg/m² | ISO 180-A |

| Nominal Strain at Break (50 mm/min) | min. 50 | % | ISO 527-1,-2 |

| Tensile Modulus (1 mm/min) | 2350.0 | MPa | ISO 527-1,-2 |

| Yield Strain (50 mm/min) | 6.0 | % | ISO 527-1,-2 |

| Value | Units | Test Method / Conditions | |

| Yield Stress (50 mm/min) | min. 60 | MPa | ISO 527-1,-2 |

| Density | 1200.0 | kg/m³ | ISO 1183-1 |

| Refractive Index (Procedure A) | 1.587 | - | ISO 489 |

| Water Absorption Equilibrium (23°C, 50% Relative Humidity) | 0.12 | % | ISO 62 |

| Water Absorption Saturation (23°C) | 0.3 | % | ISO 62 |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Thermal Expansion (23 - 55°C) | 0.65 | 10⁻⁴/K | ISO 11359-1 |

| Temperature of Deflection Under Load (0.45 Mpa) | 140.0 | °C | ISO 75-1, -2 |

| Temperature of Deflection Under Load (1.80 Mpa) | 128.0 | °C | ISO 75-1, -2 |

| Thermal Conductivity (23°C) | 0.2 | W/mK | ISO 8302 |

| Vicat Softening Temperature (50 N, 50°C/h) | 148.0 | °C | ISO 306 |

| Value | Units | Test Method / Conditions | |

| Dissipation Factor (1 Mhz) | 95.0 | 10⁻⁴ | IEC 60250 |

| Dissipation Factor (100 Hz) | 5.0 | 10⁻⁴ | IEC 60250 |

| Electrical Strength (1 mm) | 34.0 | kV/mm | IEC 60243-1 |

| Relative Permitivity (1 Mhz) | 3.0 | - | IEC 60250 |

| Relative Permitivity (100 Hz) | 3.1 | - | IEC 60250 |

| Surface Resistivity | 1e¹⁶ | Ohm | IEC 60093 |

| Volume Resistivity | 1e¹⁴ | Ohm.m | IEC 60093 |

Technical Details & Test Data

- Technical Details

EUROPEAN CERTIFICATES for Exolon® Silent Sound UV Resistance to brushwood fire according to(*) DIN EN 1794-2, Annex A: Class 2

ZTV-LSW 06, Section 2.5.4

Impact of Stones according to DIN EN 1794-1, Annex C: Passed

Danger of falling debris according to DIN EN 1794-2, Annex B: Class 3

Bird Protection according to ONR 191040 (Austrian Standards Institutes) : Passed

Anti-graffiti like(**) according to NF F 31-112

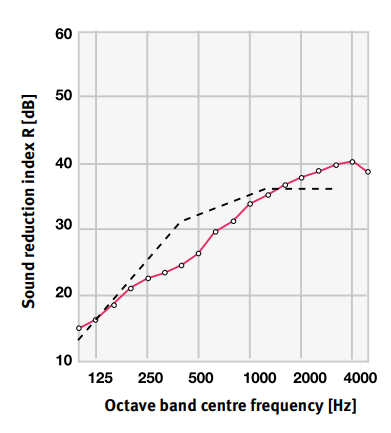

RESULTS dB [EN ISO 140-3] Sum of deviation 28.5 Average deviation 1.78 Displacement designated curve -18 Sound reduction index Rw 32 Spectrum adaptation terms C Ctr 100 – 3,150 Hz -1 -5 100 – 5,000 Hz -1 -5 50 – 3,150 Hz -1 -5 50 – 5,000 Hz -1 -5 ΔLA,R,Str (ZTV-LSW 88)

30 DLR (DIN EN 1793-2)

27 (B3) (*) Fire certificates are limited in time and scope, always check if the mentioned certificate is valid for the purchased Polycarbonate sheet type at the date of delivery. Polycarbonate sheets may change their fire behavior due to aging and weathering. The indicated fire rating was tested on new / unweathered Product in accordance with the indicated fire classification standards. (**) further information can be found in the related Technical Information