Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Benefits

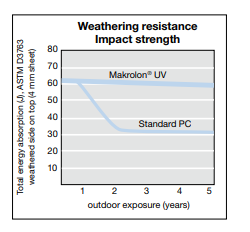

- Excellent Weathering Resistance

- Extreme Impact Strength

- Good Fire Rating

- Thermoformable

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

Exolon® UV is ideal for outdoor applications :

- Covered walkways and bus shelters

- Barrel vaults and skylights (also thermoformed)

Properties

- Physical Form

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Typical Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Charpy Impact Strength (23°C, 3 mm, Notched) | 80P | kg/m² | ISO 179-1eA |

| Charpy Impact Strength (23°C, Unnotched) | non-break | kg/m² | ISO 179-1eU |

| Flexural Modulus (2 mm/min) | 2350.0 | MPa | ISO 178 |

| Flexural Strength (2 mm/min) | 90.0 | MPa | ISO 178 |

| Izod Impact Strength (23°C, 3.2 mm, Notched) | 70P | kg/m² | ISO 180-A |

| Nominal Strain at Break (50 mm/min) | min. 50 | % | ISO 527-1,-2 |

| Tensile Modulus (1 mm/min) | 2350.0 | MPa | ISO 527-1,-2 |

| Yield Strain (50 mm/min) | 6.0 | % | ISO 527-1,-2 |

| Yield Stress (50 mm/min) | min. 60 | MPa | ISO 527-1,-2 |

| Value | Units | Test Method / Conditions | |

| Density | 1200.0 | kg/m³ | ISO 1183-1 |

| Refractive Index (Procedure A) | 1.587 | - | ISO 489 |

| Water Absorption Equilibrium (23°C, 50% Relative Humidity) | 0.12 | % | ISO 62 |

| Water Absorption Saturation (23°C) | 0.3 | % | ISO 62 |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Thermal Expansion (23 - 55°C) | 0.65 | 10⁻⁴/K | ISO 11359-1 |

| Temperature of Deflection Under Load (0.45 Mpa) | 140.0 | °C | ISO 75-1, -2 |

| Temperature of Deflection Under Load (1.80 Mpa) | 128.0 | °C | ISO 75-1, -2 |

| Thermal Conductivity (23°C) | 0.2 | W/mK | ISO 8302 |

| Vicat Softening Temperature (50 N, 50°C/h) | 148.0 | °C | ISO 306 |

| Value | Units | Test Method / Conditions | |

| Permanent Service Temperature (Without Load) | approx. 120 | °C | - |

| Value | Units | Test Method / Conditions | |

| Dissipation Factor (1 Mhz) | 95.0 | 10⁻⁴ | IEC 60250 |

| Dissipation Factor (100 Hz) | 5.0 | 10⁻⁴ | IEC 60250 |

| Electrical Strength (1 mm) | 34.0 | kV/mm | IEC 60243-1 |

| Relative Permitivity (1 Mhz) | 3.0 | - | IEC 60250 |

| Relative Permitivity (100 Hz) | 3.1 | - | IEC 60250 |

| Surface Resistivity | 1e¹⁶ | Ohm | IEC 60093 |

| Volume Resistivity | 1e¹⁴ | Ohm.m | IEC 60093 |

Technical Details & Test Data

- Weathering Resistance

Exolon® UV sheets show excellent weathering resistance, which guarantees their impact strength even after many years. Since their introduction in 1989, the sheets have been examined in an intensive test program, including a real-time outdoor exposure test in a southern European climate (Bandol). The sheets are provided with a 10-year warranty on unbreakability and on optical properties.

Packaging & Availability

- Available Sizes

Exolon® UV is available in thicknesses of 2 – 15 mm and in the following sizes :

Colors :

- Clear 2099

- White 2130

- White 2150

- Bronze 2850

- Gray 2760

- Blue 2550

- Green 2650

Sizes (Standard) :

- 3,050 x 2,050 mm

- 6,110 x 2,050 mm