Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Benefits

Softness, bonding strength, extensibility, lamination

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Uses

The use of FiberVisions® HY-Care B in nonwoven fabrics has a proven product performance regarding:

- Good nonwoven tenacities and liquid repellency characteristics

- Good cardability and a broad bonding window

- High carding speeds possible after optimization of the fiber to suit the machinery configuration

- The nonwoven fabrics have a superior softness and texture when compared to spunbonded materials The use of carded, thermal-bonded coverstock fabrics in leg cuffs and textile backsheet application ensures materials with high fabric uniformity without weak spots

- Fibers and nonwoven fabrics which can be laminated to film due to the broad bonding window

The consistent high quality and uniformity of the fibers ensure a good web uniformity, which enhances the hydrophobic properties of the nonwovens. Carded, thermal-bonded nonwoven fabrics do not have weak spots in the fabric which reduce the hydrophobicity, in contrast to spunbonded fabrics.

- Applications

Backsheet, Extensible Fabrics, Carded Thermal Bond Fabrics

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Bursting Strength Of The Fiber | 1.8-2.2 | cNidtex | Internal FV test |

| Elongation At Break | 320-370 | % | Internal FV test |

| Fiber Length (Under A Prescribed Load) | 40, 50, 60 | mm | Internal FV test |

| Raw Material (Pp) | 100 | % | - |

| Softening Point | 140-150 | °C | - |

| Melting Point | 162 | °C | - |

| Finish Level (Weight) | 0.20-0.35 | % | Internal FV test |

| Bonding Index (Combining MD And CD Tensiles) | 30-32 | N/5 cm | Formula |

| Tensile Strength (Md) | 51-55 | N/5 cm | Internal FV test |

| Tensile Strength (Cd) | 16-19 | N/5 cm | Internal FV test |

| Elongation (Md) | 55-70 | % | Internal FV test |

| Elongation (Cd) | 85-110 | % | Internal FV test |

| Water Repellency | max. 8 | cm | Internal FV test |

| Crimp Frequency Internal (KD, No. of crimps/10 cm) | Variable | Internal FV test | |

| Weight (Fiber Of 10 Km/Length) | 1.7-2.2 | dtex | Internal FV test |

Technical Details & Test Data

- Test Data

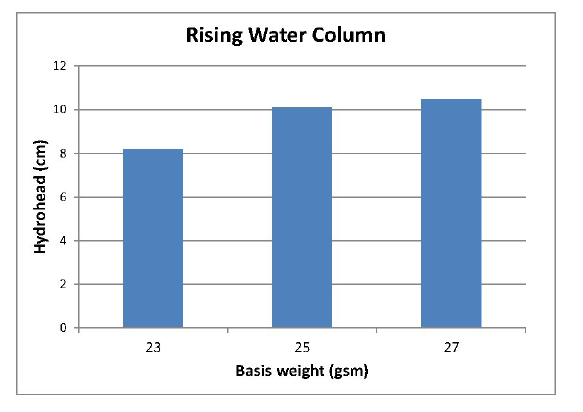

Rising Water Column

The following nonwoven repellency values (Internal FiberVisions test method) are obtained from coverstock fabrics from HY-Care B fibers in 2.2 dtex: Normally, a 1.7 dtex fiber would result in a higher rising water column test result.

Nonwoven Properties

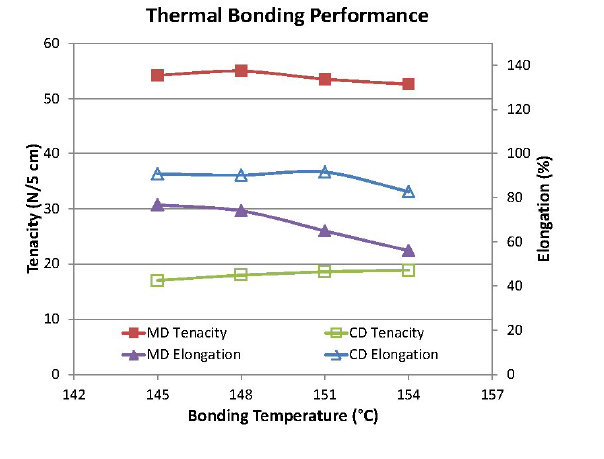

Typical thermal bonding curves from a 23 gsm nonwoven fabric produced at the FiberVisions a/s pilot carding line at a carding speed of 100 m/min:

Packaging & Availability

- Country Availability

- Regional Availability

- Availability

FiberVisions® HY-Care B fibers are available in 1.7 and 2.2 dtex. The fine fibers will increase the hydrophobicity of the nonwoven fabrics due to an decrease in pore size and the higher uniformity of the fabric.