Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Origin

The FiberVisionsâ HY-Soft is presently produced at the FiberVisions a/s plant in Denmark. HY-Soft is the trademark of FiberVisions.

Features & Benefits

- Materials Features

- Major Features Are

- Unique softness

- A fiber with good nonwoven processing:

- Broad bonding window

- Low bonding temperature

- Normal carding speed

- The nonwovens strength and elongation properties can be compared with the properties of other FiberVisionsâ fiber types

- The fiber is available in a hydrohilic as well as a hydrophobic version and various botanical finishes

With regard to other fiber properties the FiberVisionsâ HY-Soft fiber behaves in the same way as the other FiberVisionsâ longspinning fibers:

- A controlled surface characteristic ensures optimal bonding conditions

- The uniformity of the fibers ensures stable processing conditions minimizing down-time and downgraded materials

- The FiberVisions concept of adapting the fiber to suit the individual carding line maximize

- In several softness tests (internal FV method) nonwovens made of FiberVisionsâ HY-Soft score significantly higher in "softness" than other nonwovens made of other PPfiber types.

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Bursting Strength Of The Fiber | 1.7 -2.0 | cNidtex | Internal FV test |

| Elongation At Break | 350 - 400 | % | Internal FV test |

| Fiber Length (Under A Prescribed Load) | 40, 50, 60 | mm | Internal FV test |

| Raw Material (Pp) | 100 | % | — |

| Softening Point | 136 - 148 | °C | — |

| Melting Point | 159 | °C | — |

| Finish Level (Weight) | 0.35 | % | Internal FV test |

| Bonding Index (Combining MD And CD Tensiles) | 19 - 22 | N/5 cm | Formula |

| Tensile Strength (Md) | 35 - 40 | N/5 cm | Internal FV test |

| Tensile Strength (Cd) | 10 - 13 | N/5 cm | Internal FV test |

| Elongation (Md) | 50 - 70 | % | Internal FV test |

| Elongation (Cd) | 80 - 120 | % | Internal FV test |

| Strike Through Time (Hydrophilic Version) | max. 3 | sec | WSP 70.3 |

| Rewet (Hydrophilic Version) | max. 2 | g | WSP 80.10 |

| Water Rising Column (Hydrophilic Version) | Depending on spin finish | — | Internal FV test |

| Crimp Frequency Internal (KD, No. of crimps/10 cm) | Variable | — | Internal FV test |

| Weight (Fiber with 10 Km/Length) | 2.2 | dtex | Internal FV test |

Technical Details & Test Data

- Test Data

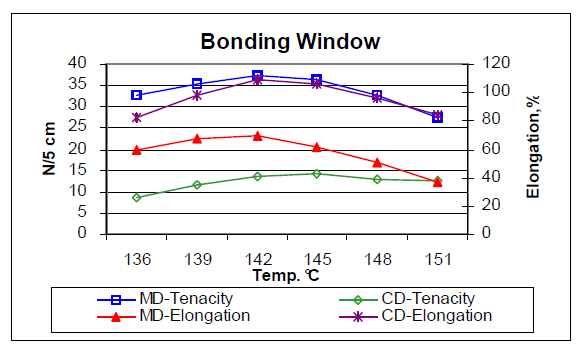

Results from FiberVisions a/s pilot carding & calendering line FiberVisions has obtained the following nonwovens data from tests on the carding & calendering line at 100 m/min carding speed (Typical data for a 20 g/m² product):

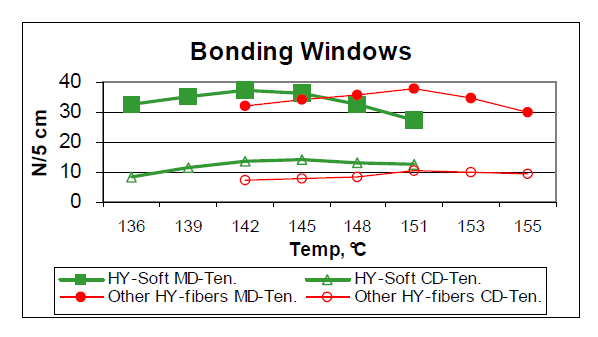

From the below graph it can be seen that nonwovens made of HY-Soft achieved their highest tenacities at approx. 8-10 °C lower temperatures than normal PP-fibers: