Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Benefits

- Aqueous-based PTFE dispersion formulation

- Wide continuous service temperature range -400°F to 550°F

- Stable in pressures up to 10,000 psi and in vacuums 10-3 Torr

- Chemically inert

- Anti-galling, anti-corrosive, anti-seize

- Prevents pipe damage on stainless steel, steel, and plastic

- Silicone free

- Insidiously wets to threads, and once dried down, will not be dislodged

- Will not cold flow over time

- Will not jam check valves, pumps, or plug orifices

- Non-migrating

- Non-toxic, solvent-free, non-hazardous, odorless, non-flammable, VOC-free

- Seals all sizes and types of threaded joints

- Permits sealing or disassembly at relatively low torques

- Engineered to replace thread sealing tapes

- Eliminates challenges associated with tape

Applications & Uses

- Markets

- Application Area

- Compatible Substrates & Surfaces

- Uses

- Natural gas applications

- Cryogenic applications

- Welding and industrial gasses

- Gasoline, diesel, kerosene fuel systems

- Hydraulic systems

- Vacuum service to 10-3 Torr

- Chlorine (gaseous and liquid) and powerful oxidizers

- Oxygen systems (gaseous and liquid)

- Valves in bottled gasses

- Water and wastewater processing

- Instruments and fine threads

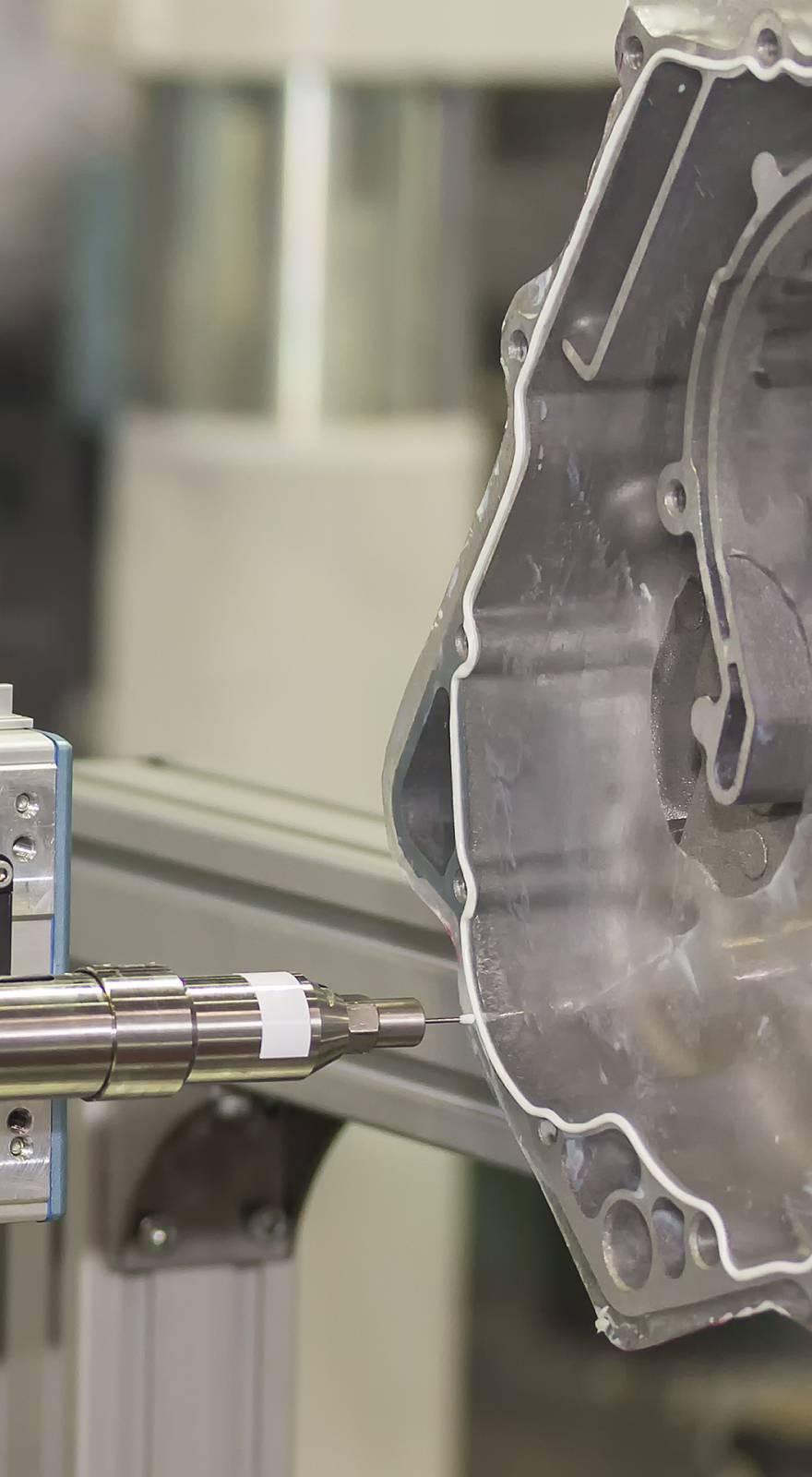

- Machine and engine sensors

- Ammonia and freon refrigeration service

- Medical

- Wafer fab

- Offshore drilling rigs

- Coal power plants

- Aerospace

- Chemical processing

- Medical

- How to Apply

Applying Thread Sealants without using Full Density PTFE Tape

- Clean the male and female threads of any dirt or oil

- Use a brass or stainless-steel wire brush to clean off any material on the threads

- Wipe down the threads using a lint free cloth and acetone

- Re-assemble

- Starting one to two threads back from the end of the male fitting, use your finger to liberally apply Formula-8 to fill the threads

- Fit and torque the male and female pieces together. Hand tighten or use standard pipe tools to torque

- Wipe off excess sealant

- Let dry down 12 hours before returning to service

- Be careful not to over-tighten fittings, especially plastic, PVC, or cast iron, as the fittings may crack

Applying Thread Sealants using Full Density PTFE Tape

On threaded joints 3⁄4” or larger, Fluoramics suggests using Formula-8 and Full Density PTFE tape

- Clean the male and female threads of any dirt or oil

- Starting two threads back from the end of the male fitting, apply two wraps of a Full-Density PTFE Tape in the direction of thread rotation, maintaining tension on the tape while wrapping

- Apply the thread sealant over the tape as instructed above

Troubleshooting Leaks

- Don’t assume the sealant failed. Look carefully at the piping and joints for cracks

- Take the joint apart to make sure there is enough sealant in the threads to form a perfect seal

- Clean the male and female threads of any dirt or oil

Properties

- Color

- Physical Form

- Odor

- Odorless

- Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Flammability | Non-Flammable | - | - |

| Flash Point | None | - | - |

| VOC (Paste) | 1.1 | % | EPA test 24 |

| VOC (Dried) | 0.0 | % | EPA test 24 |

| Dropping Point (Dried) | None | - | - |

| Service Temperature Range | -400 to 550 | °F | - |

| Vapor Pressure (Dried) | None | - | - |

| Density (Dried) | 1.2 | g/ml | - |

| Oxygen Test (AIT high pressure 6000 psi held at constant steady pressure, Dried) | 6000.0 | psi | ASTM G72 |

| Oxygen Test (AIT high pressure 6000 psi held at constant steady pressure, Dried) | 173.0 | C | ASTM G72 |

| Oxygen Test (AIT high pressure 1500 psi held at constant steady pressure, Dried) | 1500.0 | psi | ASTM G72 |

| Oxygen Test (AIT high pressure 1500 psi held at constant steady pressure, Dried) | 180.0 | C | ASTM G72 |

| Oxygen Impact Test (3015 psi & 72ft-lbs, 98J impact, Dried) | 20.0 | - | - |

| Oxygen Impact Test (3015 psi & 72ft-lbs, 98J impact, reaction Numbers) | 0.0 | - | ASTM G86 |

| BAM Oxygen Gaseous Tested, Paste (60°C) | 2320.0 | psi | - |

| BAM Oxygen Gaseous Tested, Dried (60°C) | 435.0 | psi | - |

| BAM oxygen liquid (Paste) | No Limitations | - | - |

| BAM oxygen liquid (Dried) | No Limitations | - | - |

| Solubility in Sulfuric Acid | No effect | - | - |

Regulatory & Compliance

- Certifications & Compliance

- Specifications and Approvals

- NASA-tested (ASTM G72-82 and ASTM G86)

- NSF-approved for food processing areas

- BAM-tested

- WHA high pressure oxygen tested

- Praxair GS-38 Approved

Safety & Health

- Health and Safety

Formula-8 is a very safe, solvent-free product. Not classified as hazardous according to OSHA 29 CFR 1910.1200 and WHMIS. Not hazardous under the consumer product safety regulations. Avoid contact with the eyes. Wash hands with soap and water after use. In case of eye contact: flush with water. Get medical attention if irritation persists. If swallowed, call a poison center or doctor for advice.

Packaging & Availability

- Packaging

Size Container Case Quantity NET WT: 15 grams, .53 oz. Tube 12 NET WT: 100 grams, 3.5 oz. Tube 24 NET WT: 650 grams, 1.43 lbs. Jar 12

Storage & Handling

- Storage/Shipping/Handling

- Do not store at temperatures below 0°C/32°F

- Product only freeze sensitive in the paste state

- Always keep unused product in original container, store upside down, tightly closed

- Store in a cool, dry ventilated area

- Avoid freezing and excessive heat during storage and shipping

- DOT-classified as non-hazardous, can be shipped by air with no shipping restrictions