Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Coating Type

- 20% to 45% PVC Water-based Coatings

1) Replace 10% of the TiO₂ with the same weight of FP‐460

2) Remove 10% of the largest particle size extender/filler in the formulation

This will result in a slight reduction in the PVC of the paint which helps to maintain the gloss level of the reformulated paint. At this stage the opacity of the formulation should be checked and if necessary a small level of opaque polymer (typically between 0.5% and 1.0% on total formulation weight) should be added. If opaque polymer cannot be used, then one or two percentage points of TiO₂ should be added back to the formulation.

If the replacement is successful following the 10% protocol, then further reductions can be attempted and we recommend doing this in 2.5% increments.

E.g.

1) Replace 12.5% of the TiO₂ with the same weight of FP‐460

2) Remove 10% of the largest particle size extender/filler in the formulation

3) Adjust opacity using small additions of opaque polymer or replacing some TiO₂

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Dry Solids | 99.0 | % | — |

| Brightness (ISO) | 95.0 | — | — |

| L* value | 98.8 | — | — |

| B* Value | 1.4 | — | — |

| Specific Surface Area (BET) | 10.0 | m2/g | — |

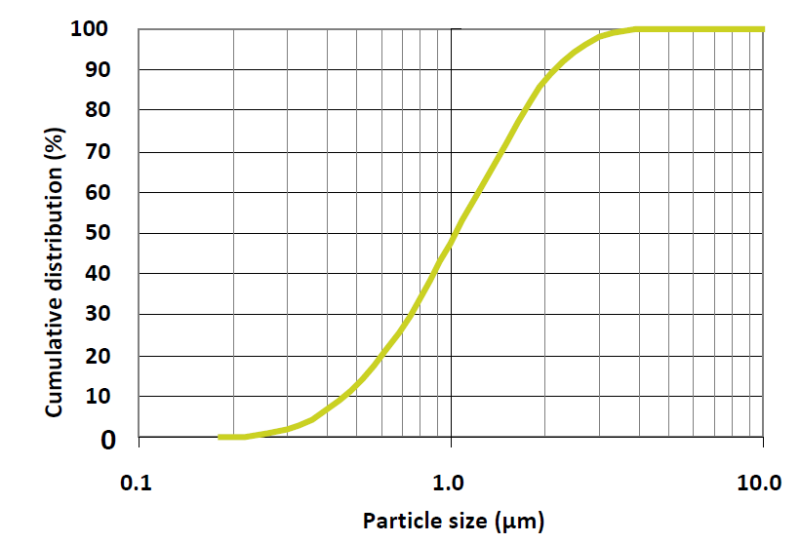

| Average Particle Size | 1.0 | μm | — |

| Specific Gravity | 2.8 | — | — |

| Oil Absorption | 43.0 | g/100g | — |

| Bulk / Tapped Density | 415 / 675 | g/l | — |

Technical Details & Test Data

- 50% to 90% PVC Water-based Coatings

1: Test using a replacement ladder of 5, 10, 15 and 20% FP-460.

2: Make a 1:1 weight for weight replacement of TiO₂ with Opacity Pigment.

3: For the optimum performance, the order of addition, where possible, should be:

i) Normal Millbase liquid ingredients and HEC thickener if present.

ii) Opacity Pigment™ followed immediately by

iii) TiO₂ Pigment

iv) then extenders

4: Mill as normal - no additional milling time is necessary.

5: Complete paint as normal.- Typical Pigment

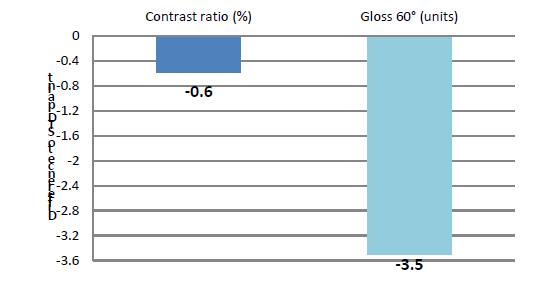

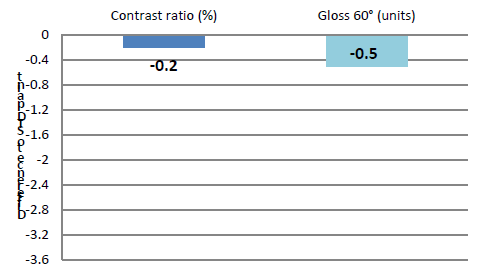

- Gloss 15

Paint PVC ˜ 30 %

• Weight to weight, 10 % TiO2 replaced

– Differences in contrast ratio and gloss are clearly visible

Comparison to STD paint

Paint Volume Solids ˜ 37 %

Reformulated, 9 % TiO2 replaced

– Successfull reformulation: Contrast ratio and gloss within target range compared to STD paint

Comparison to STD paint

STD Changes Reformulated for FP460

wt % wt % wt % TiO2 15 -1.35 13.65 FP460 0 1.35 1.35 < 1 micron GCC 12 -1.2 10.8 Opaque Polymer 0 0.6 0.6 - Contrast Ratio vs Replacement Ratio

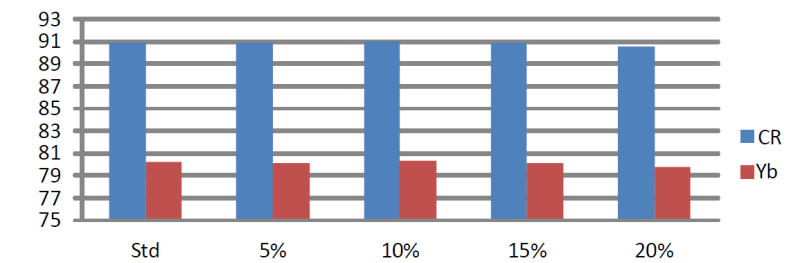

DIY Matt 78% pvc

60μm Wet Film Thickness (6 K-bar)

Replacement Ratio

Optimum replacement level lies between 15% and 20%