Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Performs well on Millwork and radio frequency applications

- Low foam production

- Good spreader stability

- Good adhesion to laminated veneer lumber and other treated wood

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Mixing Instructions

Advantage EP-930 resin is mixed with Hardener 200 at a ratio of 100 parts resin to 15 parts Hardener by weight or 6.45 parts resin to one part Hardener by volume. Avoid mixing for long periods of time or with excessive agitation as pot life is affected by mixing time and speed. While this product can be easily mixed by hand, it is usually more convenient to mix the components in a meter mix unit. Your Franklin representative can work with you to supply the appropriate mixing equipment and appropriate mixing ratios depending on your application.

- Application Guidelines

Moisture content: Six to ten percent is the recommended moisture content for the gluing stock. Higher moisture content will increase the clamp time needed. Additionally, moisture content should mirror (as closely as possible) that which will be experienced in the end use market for the wood product being manufactured.

Stock preparation: The preparation of the stock to be glued is extremely important. Joints cut from rip saws should be free of saw marks. They should also be straight and square. Molded or jointed stock should be free of knife marks. Glazed or burnished joints will prevent adhesive penetration and should be guarded against. Gluing stock should be uniform in thickness. Variation in thickness should not exceed ± 0.005 inches/0.12 mm. Sanding to thickness should be performed using higher than 50 grit abrasives.

Spread rate: The recommended adhesive coating layer is the same as for most PVA products or approximately 0.007 inches/ 0.178 mm in thickness. EPI adhesives have superior gap filling properties due to their higher percent solids content. Generally, 200 g/m² / 41 #/MSGL of glue line is adequate. Conveyorized spreaders are commonly used in edge-gluing applications. Adjust the applicator to ensure complete coverage on the staves. One side application is adequate in most situations. Verify that adequate coverage exists by monitoring squeeze-out along the glue lines when the panels are under pressure.

Clamping Pressure: Pressure is dependent upon the species or material to be glued and joint preparation. Direct contact of the gluing surfaces is required to obtain maximum strength. The use of a compressometer will aid in accurately measuring the amount of pressure being applied to the gluing area. Suggested clamp locations for various wood densities are eight to fifteen inches (20-38 cm) apart and two inches (five cm) from the end of the panel to evenly distribute pressure along the entire length of the glue line.

Recommended clamping pressures:Species Clamping pressure Example Low density wood species 100-150 psi or 7-10 kg/cm² Pine, Poplar Medium density species 125-175 psi or 9-13 kg/cm² Rubberwood, Cherry

High density species 175-250 psi or 13-18 kg/cm² Oak, Maple Assembly time: The assembly time is influenced by many factors some of which include glue spread, moisture content of the stock, porosity of the stock, environmental conditions and adhesive choice. Assembly times of five to ten minutes are approximate. It is desirable to see a bead of adhesive squeeze out around the perimeter of the bottom panel of the stack.

70ºF and 50% relative humidity, approximately 6 wet mils:

Open Assembly Time – 5 minutes

Total Assembly Time – 10 minutesPress/clamp time: A minimum press time of 30 minutes is recommended under ideal conditions when using soft wood species at moisture content less than eight to ten percent and factory temperatures of 68 degrees Fahrenheit/ 20 degrees Celsius. Longer press times will be required for higher density species, higher moisture contents and colder factory temperatures. It is recommended that optimum press times be determined in actual plant conditions recognizing that seasonal changes may lead to variable requirements.

Working pauses: The spreader should be kept running during pauses in production for lunch breaks, etc. to help extend the working life of the adhesive.

Machining: Post-gluing conditioning is not unlike PVA products, although shorter curing times are frequently possible. We recommend that panels be allowed to condition at least six hours prior to additional processing.

RF cure time: Radio frequency cure times will vary from machine to machine. Machine manufacturers suggest that machines will cure between 75 and 100 square inches of glue line per minute per kilowatt. Glue joints should feel warm immediately after the cure cycle. Cure times should be determined through plant trials.

Clean-up: The foaming and cross-linking characteristics of EPI may cause blockages in the wastewater plumbing. Furthermore, there may be disposal concerns with the mixed product. It is recommended that the excess glue from the spreader and mixing containers be poured into a container and disposed of. Avoid sealing the container for at least 24 hours to permit EPI components to finish reacting. Glue pans and rollers may then be washed in warm water.

Hot press time: Press time is dependent on the adhesive used, gluing stock type, moisture content of the stock and environmental conditions. This hot press schedule is provided as a recommended starting point. In plant testing is recommended especially for temperatures and substrate thicknesses beyond this chart.

Platen Temperature °F 160 170 180 190 200 210 220 230 240 250 Distance

to

Deepest

Glue

Line1/32” 1' 31" 1' 25" 1' 19" 1' 14" 1' 09" 1' 05" 1' 01" 0' 57" 0' 53" 0' 50" 1/16” 1' 53" 1' 46" 1' 39" 1' 33" 1' 27" 1' 21" 1' 16" 1' 11" 1' 07" 1' 02" 3/32” 2' 22" 2' 13" 2' 04" 1' 56" 1' 49" 1' 42" 1' 35" 1' 29" 1' 24" 1' 18" 1/8” 2' 58" 2' 46" 2' 36" 2' 26" 2' 16" 2' 08" 1' 59" 1' 52" 1' 45" 1' 38" 5/32” 3' 42" 3' 28" 3' 15" 3' 02" 2' 51" 2' 40" 2' 29" 2' 20" 2' 11" 2' 03" 3/16” 4' 38" 4' 20" 4' 03" 3' 48" 3' 33" 3' 20" 3' 07" 2' 55" 2' 44" 2' 33" 7/32” 5' 47" 5' 25" 5' 05" 4' 45" 4' 27" 4' 10" 3' 54" 3' 39" 3' 25" 3' 12" 1/4” 7' 15" 6' 47" 6' 21" 5' 57" 5' 34" 5' 13" 4' 53" 4' 34" 4' 17" 4' 00"

Properties

- Appearance

- White Colored Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Mixed viscosity (When Mixed) | 6000 - 11,000 | cps | — |

| Mixed viscosity (At One Hour) | 30,000 - 35,000 | cps | — |

| pH | 7.0 - 8.5 | — | — |

| Specific Gravity | 1.36 | — | — |

| Suggested Minimum Use Temperature | 46.0 | °F | — |

| Typical Viscosity | 3000 - 5000 | cps | — |

| Weight Solids | 55.0 - 58.5 | % | — |

Technical Details & Test Data

- Performance Properties

- Exceeds ASTM D-5751-99 Wet Use for Laminate Joints in Non-structural Lumber Products

- Meets DIN EN 204 D4 Classification of Thermoplastic Wood Adhesives for Non-structural Applications

Like all adhesives, proper gluing practices are needed to achieve stated performance.

Exceeds ASTM D-5751-99 Wet Use for Laminate Joints in Non-structural Lumber Products

Test Results Requirements Exposure Strength

(psi)

AverageWood

failure (%)

AverageStrength

(psi)

AverageStrength

(psi)

MinimumWood failure (% )

AverageWood

failure

(%)

minimumRoom

Temperature1550 87 680 340 60 30 Boil 897 78 567 283 50 25 Vacuum

pressure947 65 567 283 50 25 Elevated

Temp.1421 90 453 227 40 20

DIN EN 204 D4 Classification of Thermoplastic Wood Adhesives for Non-structural Applications: Load group D4 BeechStorage sequence Minimum required average value

(N/mm2)Average value (N/mm2) on

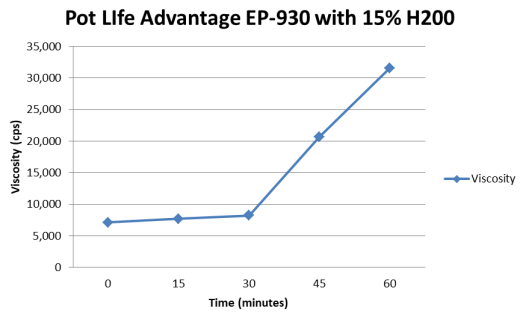

Advantage EP-9303 ≥ 4 5.02 5 ≥ 4 5.7 - Pot Life

The pot life of these systems is in excess of one hour at 77 degrees Fahrenheit (twenty five degrees Celsius). However the viscosity of the mix will increase as it ages. Wood glued with older material will have less water resistance, a characteristic common to most EPI adhesives. Therefore, it is recommended that fresh adhesive be mixed only when it is to be immediately used. EPI adhesives also generate foam during the reaction process; so we recommend keeping the material moving continually.

Storage & Handling

- Storage and Handling

Shelf life: Best if used within four months of date of manufacture. Please mix before use since it very common for filler to settle out during aging. Product is freeze-thaw stable. If it becomes frozen, allow to warm to ambient temperature and thoroughly mix until a homogenous, smooth mixture is obtained.

Storage of Hardener: Hardener 200 is very susceptible to moisture. We recommend that it be kept in a sealed container. A desiccant or nitrogen blanket is recommended.

Safety and disposal: Hardener 200 is a polymeric isocyanate. Use of gloves and other protective equipment is recommended.