Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Works with borated substrates

- Excellent for lamination

- High water-resistance

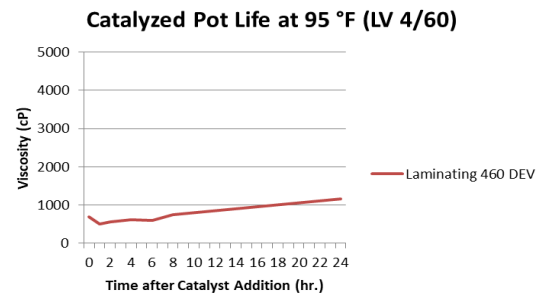

- Excellent pot life

- Passed screening test of CARB ATCM Phase 2 (ASTM D 6007-14) on ¼” 3-ply birch HWPW-VC

- Compliant with California’s South Coast Air Quality Management District’s Rule 1168

Applications & Uses

- Applications

- Application Method

- Compatible Substrates & Surfaces

- Mixing Instructions

The recommended proportion of catalyst to resin is five percent by volume or six percent by weight. Place the resin in a mixer and slowly add catalyst under agitation. Continue mixing for five to ten minutes after the catalyst is added to ensure a homogeneous mixture. A smaller amount of catalyst can be used under certain conditions, but water resistance performance should be validated. It is best to mix the catalyzed material if it has been kept for longer than seven to eight hours since it will increase in viscosity with time.

- Application Guidelines

Machinery: Product can only be hot or cold pressed, and is not intended for heat-assisted rotary laminators or pinch roll/dead stack.

Moisture content: Six to eight percent is the recommended moisture content for the gluing stock. High moisture content will dramatically increase the clamp time needed. Panel shrinkage may occur resulting in stress cracks or end-joint delamination.

Stock preparation: The preparation of the stock to be glued is extremely important. Joints cut from rip saws should be free of saw marks. They should also be straight and square. Molded or jointed stock should be free of knife marks. Glazed or burnished joints will prevent adhesive penetration and should be guarded against. Gluing stock should be uniform in thickness. Variation in thickness should not exceed ± 0.005 inches/0.12 mm. Sanding to thickness should be performed using higher than 50 grit abrasives. When possible, glue joints should be prepared and glued the same day.

Spread: Generally, 35-50 pounds of adhesive per 1,000 square feet or 170-250 grams per square meter of glue line is adequate. Verify adequate glue coverage by monitoring for squeeze out along the glue line once the panels are under pressure.

Pressure: Pressure is dependent upon the species or material to be glued and joint preparation. Direct contact of the gluing surfaces is required to obtain maximum strength. The use of a compressometer will aid in accurately measuring the amount of pressure being applied to the gluing area. Suggested clamp locations for various wood densities are eight to fifteen inches (20-38 cm) apart and two inches (five cm) from the end of the panel to evenly distribute pressure along the entire length of the glue line.

Recommended clamping pressures:Species Clamping pressure Example Low density wood species 100-150 psi or 7-10 kg/cm² Pine, Poplar Medium density species 125-175 psi or 9-13 kg/cm² Rubberwood, Cherry

High density species 175-250 psi or 13-18 kg/cm² Oak, Maple Assembly time: The assembly time is influenced by many factors some of which include glue spread, moisture content of the stock, porosity of the stock, environmental conditions and adhesive choice. Assembly times of five to ten minutes are approximate. It is desirable to see a bead of adhesive squeeze out around the perimeter of the bottom panel of the stack.

70ºF and 50% relative humidity, approximately 8 wet mils: Total Assembly Time – 20 minutesPress/clamp time: Press times are dependent on the adhesive used, gluing stock type, moisture content of the stock, and environmental conditions. Press times can range from a minimum press time of 30 minutes to greater than two hours. Shorter times are required under ideal conditions when using soft wood species at moisture content slightly less than eight to ten percent and factory temperatures of 68 degrees Fahrenheit/ twenty degrees Celsius. Longer press times will be required for higher density species, higher moisture contents and colder factory temperatures. It is recommended that optimum press times be determined in actual plant conditions recognizing that seasonal changes may lead to variable requirements.

Machining/ post process conditioning: After the minimum clamping time period, the panel will develop enough handling strength and can be removed and stacked out of the press. Twenty-four hours of cure is recommended before further machining. Three or four days may be required to eliminate sunken joints caused by residual moisture in the glue line.

Minimum use temperature: Curing temperatures should be higher than the minimum use temperature of the adhesive. This includes the temperature of the stock to be glued as well as the air and adhesive temperatures. If the temperatures are below the minimum use temperatures you will see a white, chalky appearance of the glueline. These bonds are usually weak.

Clean-up: For easy removal of adhesive from equipment, clean up while it is still wet with warm water (this includes the glue roller and pans). For dried glue, steam and or hot water are the most effective. Using glue release agents on equipment will also allow for easier clean up.

Hot press time: Press time is dependent on the adhesive used, gluing stock type, moisture content of the stock and environmental conditions. This hot press schedule is provided as a recommended starting point. In plant testing is recommended especially for temperatures and substrate thicknesses beyond this chart.

Platen Temperature °F 160 170 180 190 200 210 220 230 240 250 Distance

to

Deepest

Glue

Line1/32” 1' 31" 1' 25" 1' 19" 1' 14" 1' 09" 1' 05" 1' 01" 0' 57" 0' 53" 0' 50" 1/16” 1' 53" 1' 46" 1' 39" 1' 33" 1' 27" 1' 21" 1' 16" 1' 11" 1' 07" 1' 02" 3/32” 2' 22" 2' 13" 2' 04" 1' 56" 1' 49" 1' 42" 1' 35" 1' 29" 1' 24" 1' 18" 1/8” 2' 58" 2' 46" 2' 36" 2' 26" 2' 16" 2' 08" 1' 59" 1' 52" 1' 45" 1' 38" 5/32” 3' 42" 3' 28" 3' 15" 3' 02" 2' 51" 2' 40" 2' 29" 2' 20" 2' 11" 2' 03" 3/16” 4' 38" 4' 20" 4' 03" 3' 48" 3' 33" 3' 20" 3' 07" 2' 55" 2' 44" 2' 33" 7/32” 5' 47" 5' 25" 5' 05" 4' 45" 4' 27" 4' 10" 3' 54" 3' 39" 3' 25" 3' 12" 1/4” 7' 15" 6' 47" 6' 21" 5' 57" 5' 34" 5' 13" 4' 53" 4' 34" 4' 17" 4' 00"

Properties

- Appearance

- Beige Colored Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH (Catalyzed) | 2.0 - 4.0 | — | — |

| pH (Uncatalyzed) | 6.5 - 8.0 | — | — |

| Specific Gravity | 1.11 | — | — |

| Suggested Minimum Use Temperature | 53.0 | °F | — |

| Typical Viscosity Catalyzed | 1000 - 3000 | cps | — |

| Typical Viscosity Uncatalyzed | 2100 - 4100 | cps | — |

| Weight | 9.3 | Pounds per Gallon | — |

| Weight Solids | 46.5 - 56.1 | % | — |

Technical Details & Test Data

- Pot Life

Storage & Handling

- Storage and Handling

Best if used within four months of date of manufacture. Product is freeze-thaw stable. If it becomes frozen, allow to warm to ambient temperature and thoroughly mix until a homogenous, smooth mixture is obtained.