Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Tube and Rod Sizes

Rod sizes Diameter Diameter with Over-extrusion Product code inches mm inches mm R96 0.378 9.6 0.394 10 Other diameters, wall thicknesses and over-extrusion thicknesses can be produced on request.

Features & Benefits

- Materials Features

- Product Highlights

- High strength and stiffness

- Excellent corrosion resistance

- Low weight

- Thermoformable

- High toughness

- Non-conductive

- Electromagnetic transparency

- Low thermal conductivity

- Easy to cut and fabricate

- Product Features

- Color

- Anti-static

- Soft touch

- Special effects

- Abrasion resistance

- Surface texture

- U/V stability

- Enhanced chemical resistance

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Flexural Modulus | 34 - 41 | GPa | — |

| Flexural Strength | 700 - 1000 | MPa | — |

Technical Details & Test Data

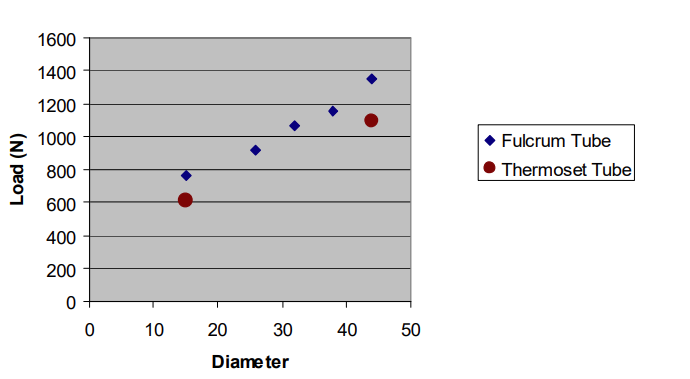

- Fulcrum Tube Testing (Ultimate Strength)

1.5mm wall, 0.5mm overcoat, t/set 2mm wall