Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

- Being used outdoors, plastic components are exposed to the ultraviolet radiation of the sun, detrimental chemical substances in the atmosphere and mechanical influences. This harmful impacts are causing damages and reducing the lifespan of a product significantly. But even indoors, plastic products are not always safe: regular use damages the surface, which affects functionality and esthetics. Ultimately, this also affects the value of the product.

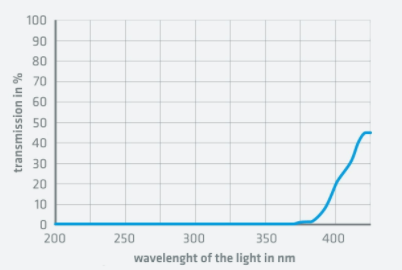

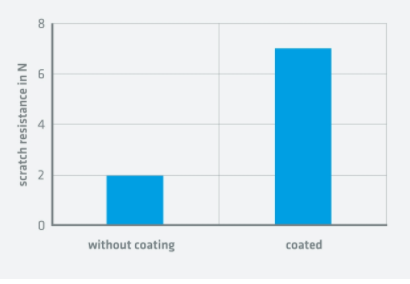

- GBneuhaus provides a range of innovative nano-coatings, including the GBprotect plastics application that provides protection against these hazardous influences as well as it ensures that high-quality components retain their optical features and maintain their performance. GBprotect plastics creates a barrier that minimizes the permeability for UV-light. Due to this the substrate will be effectively protected against the UV-rays. Furthermore GBprotect plastics prevents damages caused by mechanical influences thanks to the nanoparticles that build a glass-like protective layer with a higher scratch-resistance than the substrate. In this way an effective scratch protection is created.

Applications & Uses

- Markets

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Substrates

Plastics (PC, PMMA, ABS and more)

- Applications Examples

- Displays

- Keyboards

- Coverings

- Decorative Surfaces

- Cases

- Sensors

- Handles

- Buttons

- And Many More

Properties

- Typical Properties

- Properties of GBprotect Plastics

- Protection against UV-radiation and detrimental substances in the atmosphere.

- Reduction of UV-spectrum (200 – 380 nm) to less than 1%.

- Combined filter effect in the visible spectrum on request.

- Combination with hydrophobic effect on request.

- Abrasive hardness (cross-cut test according to DIN EN ISO 2409)

- Chemical-proof to customary detergents and disinfection methods.

- Mechanically flexible

| Value | Units | Test Method / Conditions | |

| Film Thickness | 5 -10 | µm | - |

| Maximum Temperature Load | 200.0 | °C | - |

| Pencil Hardness | max. 10 | H | ISO 15184 |

| Scratch Hardness | max. 20 | N | DIN EN ISO 1518 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Scratch Resistance of Polycarbonate

- UV Protection