Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Putty Type

- Single-component acetic silicone, high modulus of elasticity, cross-links on contact with air humidity.

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Advantages

- Excellent adhesion to many smooth substrates.

- Resists extreme temperatures: from 70°C to +230°C

- Excellent resistance to diluted acids and bases, common solvents and hydrocarbons.

Applications & Uses

- Applications

- Applications

- Silicone sealant for jointing and technical bonding: Sealing, caulking and bonding (glass/glass and glass/metal).

- Waterproofing between even submerged tiles (after complete cross-linking) in the field of swimming pools, spas and balneotherapy facilities.

- Production of in-situ seals for pumps, compressors, electric motors, gearboxes, thermostats, casings.

- Replacement of worn or damaged seals, air ducts, ventilation ducts, boxes, electrical cabinets and passages of electrical wires.

- Installation of aquariums (translucent version).

- Implementation

Preperation

- The work must be carried out in accordance with DTU 39 / NFP78 201 standard.

- Glass, tiles: degrease with alcohol followed by wiping with a clean cloth.

- Metals, aluminum: removal of rust and passivation of supports. If necessary, sanding with abrasive, degreasing with alcohol followed by wiping with a clean cloth. For anodized aluminum, only degreasing is required.

- Plastics: Abrasive sanding, degreasing with a solvent recommended by the manufacturer, and flame treatment if necessary (carry out preliminary tests).

- In general, the substrates must be sound, dry, dust-free and free from fatty substances.

Manual

- Apply masking tape if necessary.

- Apply the sealant with a manual or pneumatic gun (no reheating is necessary). Under no circumstances may the mastic be applied submerged or on wet surfaces.

- Depending on the work to be done (sealing, caulking or gluing), either smooth the joint with a damp spatula in order to press the mastic against the support, or crush the bead of mastic with the second surface to be bonded.

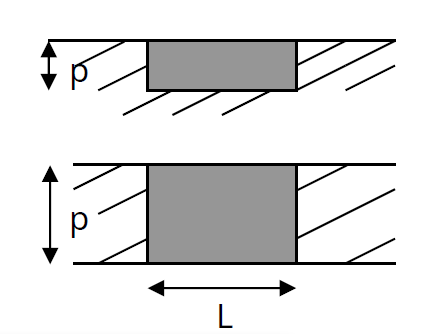

Consumption

Depending on the dimensions of the joint and the application, a 310 ml cartridge will make a joint of one length (the length of the joint is expressed in meters):

Depth Width in mm (l) in mm (p) 8 10 15 20 25 30 4 9.6 7.7 5.1 3.8 3.1 2.5 5 7.7 6.2 4.1 3.1 2.4 2 7 5.5 4.4 2.9 2.2 1.7 1.4 8 4.8 3.8 2.5 1.9 1.5 1.2 10 - 3.1 2 1.5 1.2 1 12 - - 1.7 1.2 1 0.8 15 - - 1.3 1 0.8 0.6 20 - - - 0.7 0.6 0.5

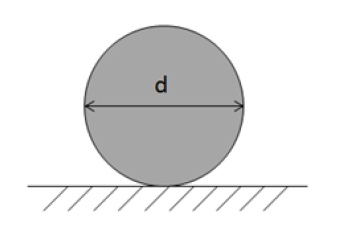

Bead diameter in mm (d)

4 6 8 10 12 Length

seal24.5 10.9 6 3.8 2.6

Equipment cleaning

The equipment is cleaned with a solvent (white spirit, acetone or ethyl alcohol) before the sealant dries and by scraping after hardening.

Properties

- Appearance

- Translucent,Non-flowing dough

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Application Temperature | 5 - 40 | °C | — |

| Density | 1.04 | — | — |

| Elongation (break, On reticulated joint) | 3.0 | — | on glass specimens according to NF EN ISO 8339 |

| Hardness (On reticulated joint) | 23.0 | Shore A | ISO 868 |

| Modulus (100% elongation, On reticulated joint) | 0.5 | MPa | on glass specimens according to NF EN ISO 8339 |

| Setting Speed (per 24h) | 3.0 | mm | — |

| Sticky Loss Time | 20.0 | minutes | — |

| Straightening Time | 5.0 | minutes | — |

| Tear Resistant (On reticulated joint) | 1.0 | MPa | on glass specimens according to NF EN ISO 8339 |

Regulatory & Compliance

- Labels and Approvals

CE marking: DoP - Sealant used for glazing: EN 15651-2 G Tested by Eurofins Expertises Environnementales in order to validate the safety with respect to fish: under

the experimental conditions of the trial, the use of this translucent sealant for the manufacture of aquariums did not cause any mortality or abnormal behavior fish (Brachydanio rerio).

Technical Details & Test Data

- Technical Characteristics

On Reticulated Joints Temperature resistance

From –50°C to +230°C (260°C peak) for white, translucent and gray

From –50°C to +250°C (300°C peak**) for blackResistance Excellent against ozone, saline mist, diluted acids and bases, common solvents and hydrocarbons, treated swimming pool water.

Adhesion Very good on many smooth surfaces: glass, aluminum, ceramic, etc.

** results based on 96 hours at 300°C. Over this period, the loss of mass and volume does not exceed 13%. The tensile stresses must not exceed 0.8 kg/cm² and an expansion greater than 59%

- Comments

In most cases of sealing, when the joint is confined and little stressed, this sealant can be applied to wood, metals and plastics. In the case of technical bonding, where the joint is mechanically stressed, it is recommended to use an adhesion primer (ref. 10073 on raw or anodized aluminum, metals and rigid plastics and ref. 12076 on concrete and wood). Refer to the technical data sheets for these primers for application. On certain unprotected metals, risk of corrosion. Not recommended on special treated lenses.

Storage & Handling

- Storage

Store at a temperature between -5°C and +30°C. The expiry date noted on the packaging is measured on the unopened product, stored at 20°C under normal humidity conditions.