Knowde Enhanced TDS

Identification & Functionality

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Process Suitability

PROCESS FIBER VOLUME FRACTION (%) MOLDABILITY PROCESSING TIME Prepreg Press Molding 30 - 36 Excellent Low Prepreg Autoclave Molding 22 - 28 Good Medium-High LCM 30 - 38 Very Good Low HP RTM 30 - 38 Good Low-Medium Vacuum infusion 14 - 18 Very Good Medium Wet Layup 8 - 12 Good Medium - Product Highlights

- G-TEX M is our range of 100% recycled carbon fiber nonwoven mats. These mats provide an excellent balance of mechanical properties, formability and high-quality surface finish.

- G-TEX M nonwoven mats can be used with all commonly used resin systems for composites. Whilst best suited for compression molding processes in either dry or pre-impregnated forms, they are also used today in vacuum infusion (dry mats) and autoclave (pre-impregnated mats) processes.

- G-TEX M nonwoven mats are used today in automotive, wind energy, marine and tooling applications.

- Features

- Fiber areal weights from 50-500 gsm available as standards.

- Standard widths from 1.0 – 2.5m.

- Excellent formability

- High bulk factor giving rapid build up of laminate thickness and ability to accommodate thickness variations and design details in closed mold processes.

- Excellent surface finish with no print through.

Applications & Uses

- Applications

- Compatible Reinforcements

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength (Transverse) | 330.0 | MPa | — |

| Tensile Modulus (Transverse) | 35.0 | GPa | — |

| Compression Strength (Transverse) | 330.0 | MPa | — |

| Compression Modulus (Transverse) | 30.0 | GPa | — |

| Flexural Strength (Transverse) | 500.0 | MPa | — |

| Density | 1.51 | g/m³ | — |

| Tensile Strength (Longitudinal) | 290.0 | MPa | — |

| Tensile Modulus (Longitudinal) | 25.0 | GPa | — |

| Compression Strength (Longitudinal) | 270.0 | MPa | — |

| Compression Modulus (Longitudinal) | 20.0 | GPa | — |

| Flexural Strength (Longitudinal) | 370.0 | MPa | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

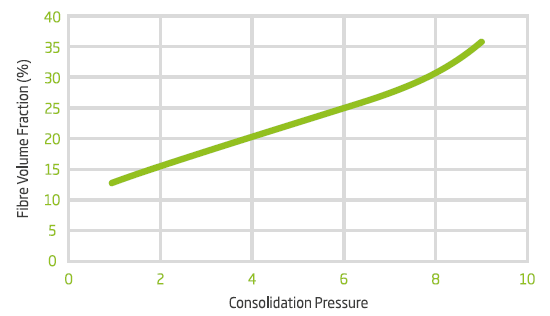

- Relationship between FvF and Consolidation Pressure

Safety & Health

- Health and Safety

Gen 2 Carbon certifies that our recycled carbon fiber products are compliant with the European Union Regulation (EC) 1907/2006 governing the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and do not contain substances above 0.1% weight of a Substance of Very High Concern (SVHC) listed in Annex XIV. Advised precautions for safe handling are general PPE (gloves, safety goggles, mask and protective clothing).

Packaging & Availability

- Packaging Type

- Product Range

DESCRIPTION VALUES Fiber Type Standard Modulus: SM45 and Intermediate Modulus: IM56 Areal weight [gsm] 50 - 500 Roll width [mm] 500 - 2500 Roll length [m] 25 - 100 - Packaging

Sealed in polythene bag.

Storage & Handling

- Storage

- Storage life: 24 Months

- Storage Style: Once outside the packaging, roll cores must be supported and laid flat to avoid telescoping and flattening.

- Temperature and Humidity: Store in a cool and dry environment