Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Coating Thickness | .001" - .100" | — | — |

| Tensile Strength | 6500.0 | psi | — |

| Impact Resistance (Izod, Notched, 73°F) | No Break | ft.lb./in | — |

| Durometer Hardness | 67.0 | Shore D | — |

Technical Details & Test Data

- Chemical Resistance

- Excellent chemical resistance

- Exceptions - Exposure to very strong oxidizing acids such an Nitric Acid, some organic acids such as Sulfonic Acid and bases such as amines, in high concentrations and near their boiling points will affect TEFLON® ETFE to varying degrees.

- Technical Details

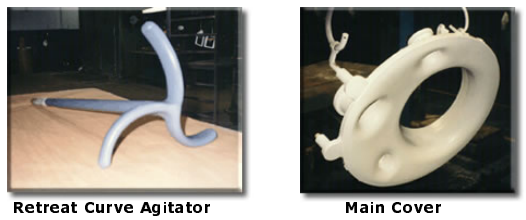

Previously Glass-Lined Reactor Accessories

Parts up to 8' x 8’ x 25’ - Vessels, agitators, baffles, centrifuge housings and baskets, columns, pump housings, dip-tubes, spargers, thermowells. manway covers, and dust collectors. Previously glass-lined tanks and accessories can be refurbished to like-new condition.