Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Item Description

Item Description Item Number* Part 1 and kit (Dispensing Accessories)

Part 1 in 48 lb pressurized canister, 25' (8 m) hose and gun assembly, six mix tips, three 17ʺ (432 mm) extension tubes; 9/16ʺ (14 mm) wrench; one packet O-ring lubricant.W59RACIAPC1 Part 2

Part 2 in 44 lb pressurized canister.W59RACIAPC2 Quick Dual Hose and Gun

25' (8 m) hose and gun assembly, allows dispensing Quick Dual 25' (8 m) from canisters. The gun assembly has a trigger lock to prevent accidental dispensing.W59RACIAPRK Quick Dual Mixing Tips

10 Mixing Tips per bag.W59RACIAPRT Quick Dual Extension Tubes

17ʺ (432 mm) extension tube that allows roofers to stand upright during application for better ergonomics and less fatigue. 10 Extension Tubes per bag.W59RACIAPRE *NOTE: Each item bearing an item number is sold separately.

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Method of Application

Quick Dual Adhesive Canister Operating Instructions

Quick Dual is dispensed in a semi-foamed bead that expands to several inches while rising ¾" to 1ʺ (19 to 25 mm) above the substrate. A chemical reaction occurs that secures the board in approximately 4 to 8 minutes after application, depending on temperature and weather conditions. It is important to determine the open/mate time for the ambient conditions encountered before attempting adhesion.

- Install only as much roof insulation or membrane as can be made watertight during that working day.

- Substrates to receive Quick Dual must be clean, smooth, dry, free of sharp edges, loose and foreign materials, oil, grease, and other contaminants.

- Install Quick Dual only when ambient conditions, bonding substrates and insulations range from 40 °F (4 °C) to 100 °F (38 °C).

- Determine the open/mate time relative to ambient conditions before attempting adhesion (see below).

- Dispense a small amount of Quick Dual into a waste container to verify proper mixing and extrusion of Part 1 and Part 2 before dispensing on substrate.

Instructions For Attaching Hoses To Canisters

- Remove hose and gun assembly from Part 1 carton.

- Remove canisters of Part 1 and Part 2 from their carton.

- Shake Canisters Part 1 and Part 2 back and forth 30 times to get best mix. Replace canisters Part 1 and Part 2 back in each respective carton and insert hoses through holes in side of each carton.

- Attach swivel fitting on the red striped hose, finger tight, to the valve outlet on top of the Part 1 canister (red).

- Attach fitting on the clear hose, finger tight, to the valve outlet of the Part 2 canister (white).

- Tighten both fittings with the 9/16ʺ wrench (provided) by turning an additional 1/6 turn until firmly attached. DO NOT OVER TIGHTEN!

- Close lid of each carton to protect from sun, wind and dirt.

Application Of Mix Tips

- Apply lubricant to black rubber O-ring on gun.

- Insert mix tip over O-ring on gun and twist to “lock” it in place.

- Extension Tubes may be attached to mix tip end to facilitate bead application of Quick Dual.

For Insulation Attachment

- Apply Quick Dual on the substrate in 1¼ʺ (32 mm) beads spaced maximum 12ʺ (305 mm) on center or as specified to meet wind uplift requirements. Allow adhesive to reach the open/mate time (see below) and set suitable insulation boards into position.

- Place maximum 4' x 4' (1.2 m x 1.2 m) insulation boards into Quick Dual Insulation Adhesive within the identified mate time.

- Immediately after setting the insulation board, provide continuous pressure using weighty objects such as adhesive pails on the insulation until the adhesive sets (typically 4-8 minutes) to ensure adequate contact between the insulation, substrate and adhesive during the critical set-up period.

For Ez Fleece Backed Tpo Membrane Attachment (Horizontal Application)

- Unroll and position EZ Fleece Backed TPO Membrane, overlapping in shingle fashion wherever possible.

- Allow EZ Fleece backed TPO Membrane to relax in its final intended position for a minimum of 30 minutes.

- Back-roll the properly positioned membrane panels to expose the substrate to receive Quick Dual adhesive. (Do not “butterfly” large areas of roof membrane during adhesive application.) Take care not to move or otherwise disturb EZ Fleece Backed TPO Membrane from its final intended position while back-rolling.

- Dispense Quick Dual onto the substrate as follows:

- Bead Application: Apply Quick Dual Adhesive on the substrate in ¾" - 1" (19 mm - 25 mm) wide beads, spaced maximum 12" (305 mm) on center.

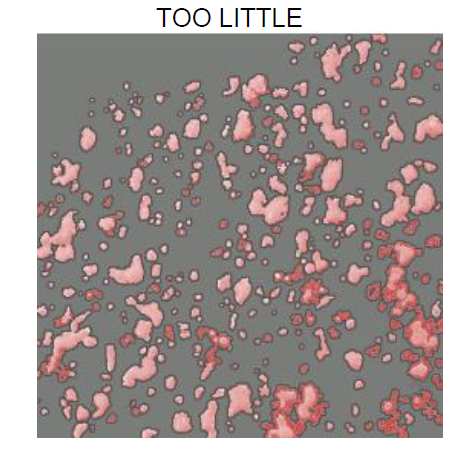

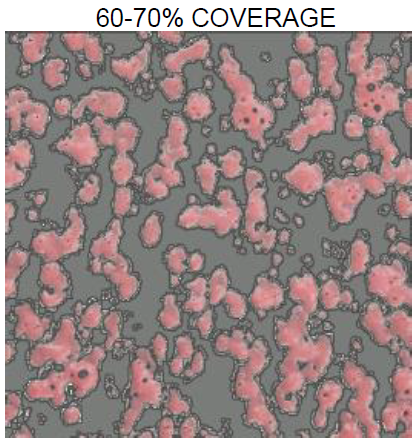

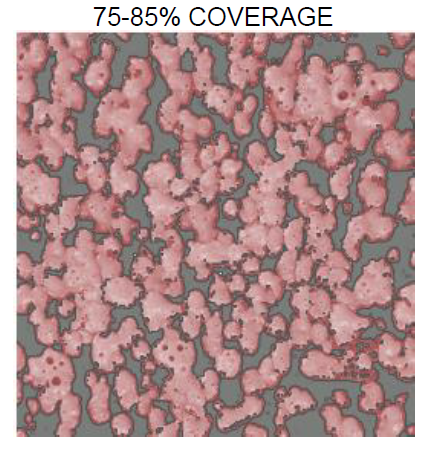

- Spatter Application: Spatter Quick Dual at a rate of 60-70% coverage over the horizontal substrate and 75-85% at base tie-in locations, 2200 ft² (204 m²) to 2350 ft² (218 m²) per cannister set.

- Do not apply Quick Dual Adhesive to EZ Fleece backed TPO Membrane. Keep lap areas of Membrane clean and free of Quick Dual Adhesive overspray. Remove any Adhesive from the seam area before mating the seam.

- Allow the adhesive to rise in height and reach open/mate condition. Mate the EZ Fleece Backed TPO Membrane to the substrate before a skim coat develops on the adhesive (See Reaction Time below).

- Immediately after setting the membrane in the Quick Dual Adhesive, broom the membrane then roll thoroughly using a 75 lb (34 kg) to 150 lb (68 kg) roller. It is important that the freshly installed membrane and substrate remain in contact with the Quick Dual Adhesive until the adhesive sets to ensure proper adhesion.

- Shelf Life

12 months with above storage recommendations.

- Clean-Up

Protect all surfaces in the immediate area of application from accidental contact with adhesive. Uncured foam may be cleaned off by using any commercially available polyurethane foam cleaner.

- PartPartially Used Canisters

- Turn the valves on each canister to the OFF position.

- Do not drain the chemical from the hoses.

- Slide the safety on the applicator gun into the LOCKED position.

- Remove the old mix tip, but do not discard. Clean the end of the gun to ensure the chemical exit ports are not obstructed.

- Apply fresh lubricant to the black rubber O-ring on gun. Re-attach the old mix tip, which, clogged with adhesive, will keep air and moisture out of the gun and hoses.

- After every 7 days without use, dispense a small amount of chemical to prevent crystallization from occurring in the hoses (no mix tip required for this).

- Remaining contents must be dispensed within 30 days of the date of initial use.

- Do not transfer used hoses to a new canister set in order to prevent cross-contamination.

- Acceptable Substrates

Substrate: NOTE: Structural Concrete (New) New poured decks must have a minimum 28-day cure time.Structural Concrete (Existing) Positive adhesion test required.Steel New steel decks may require cleaning to remove processing oils.Gypsum Positive adhesion test required.Existing Asphalt and Modified Bitumen Roofs (Mineral or Smooth Surfaced) Positive adhesion test required.Lightweight Concrete Acceptable Lightweight concrete substrates include cellular or air-entrained concrete. Lightweight concrete substrates with aggregate (such as perlite or vermiculite) are not acceptable.Plywood ⅝" (16 mm) thick minimumGenFlex Nailbase ISO / GenFlex NB ISO, GenFlex HD Polyiso / GenFlex HD ISO, Coated Glass Facer / GenFlex CG ISO, High Density Wood Fiberboard, GenFlex Polyiso / GenFlex GL ISO (Flat and Tapered), Structodek HD Fiberboard Non-GenFlex brand insulations require a positive adhesion test.Existing Single-Ply roofs Not acceptable Fiberglass Insulation Not acceptable Perlite Insulation Not acceptable Existing substrates containing residual asphalt must be cleaned and scraped smooth as possible. The substrate shall be smooth, flat, clean, dry, free of sharp fins, or foreign materials. All perimeters, deck seams and all penetrations must be sealed to prevent air infiltration through the deck. GenFlex recommends an expanding foam or similar product be used. - Coverage Rate

- Bead dispensed at 12ʺ (305 mm) o.c. up to 3500 ft² (325 m²) per set

- Bead dispensed at 6ʺ (152 mm) o.c. up to 1750 ft² (162.5 m²) per set

- Bead dispensed at 4ʺ (102 mm) o.c. up to 1167 ft² (108.3 m²) per set

- Spatter dispensed at 0.318 gal/sq. minimum – 2200 ft² (204 m²) to 2350 ft² (218 m²) per canister set.

Properties

- Component A

- Component B

| Value | Units | Test Method / Conditions | |

| Base | Diisocyanate | - | - |

| Viscosity (77 °F, 25 °C) | 160 - 240 | cPs | - |

| Density | 10.0 - 10.6 (1.2 -1.27) | lb/gal.(Kg/l) | - |

| Specific Gravity | 1.2 - 1.27 | - | - |

| Weight of full canister | 46 - 50 | lb | - |

| Max Ratio (By Volume) | 1:1 | - | - |

| V.O.C. Content | max. 25 (0.21) | g/L (lb/gal) | - |

| Value | Units | Test Method / Conditions | |

| Base | Polyol | - | - |

| Viscosity (77 °F, 25 °C) | 150 - 350 | cPs | - |

| Density | 8.2 - 8.8 (0.98 - 1.05) | lb/gal.(Kg/l) | - |

| Specific Gravity | 0.98 - 1.05 | - | - |

| Weight of full canister | 42 - 46 | lb | - |

| Max Ratio (By Volume) | 1:1 | - | - |

| V.O.C. Content | max. 25 (0.21) | g/L (lb/gal) | - |

Technical Details & Test Data

- Reaction Time

- Open/mate time - The time at which long “strings” of tacky material can be pulled away from the surface of the foam when the surface is touched by the edge of a tongue depressor blade or similar implement.

- Tack-free state - The time when the upper surface of the material can be touched by tongue depressor blade or gloved finger without sticking.

- • Apply Quick Dual Adhesive to deck substrate, when ambient and substrate temperatures range between: 40°F to 100 °F.

- Surfaces must be mated after the Quick Dual reaches open/mate time, typically 3-5 minutes, but before the adhesive reaches tack-free state, usually 8-9 minutes.

Safety & Health

- Precautions

- Review applicable Safety Data Sheets prior to use.

- Personnel who are sensitive/allergic to isocyanate or polyurethane should not work with Quick Dual.

- At the start and throughout each workday, create test samples with Quick Dual to verify proper mixing, set-up and overall adhesion of insulation to substrate before proceeding.

- Avoid contact with eyes. Wear safety glasses with side shields.

- Avoid breathing vapors. A Self-Contained Breathing Apparatus or Respirator should be used during limited ventilation periods.

- Avoid contact with skin. Wear gloves when dispensing. Wash hands thoroughly after handling.

- Close canister valves when not in use.

- Do not sit or stand on cartons or canisters.

- Do not expose product to open flame or temperatures above 100 °F.

- Canisters and contents must be brought to temperature between 70°F – 90°F for use.

- Insulation boards shall not exceed 4' x 4' (1.2 m x 1.2 m).

- Replace mix tip and extension tube after 30 seconds of non-use.

- Keep two-component canisters in upright position while dispensing adhesive.

- Do not pull or lift canisters by the hoses.

- Do not dispense adhesive in areas of spark, open flame or other ignition sources. Do not smoke in areas where Quick Dual adhesive is being applied.

- When using a full canister set, pull the trigger gradually until you reach the desired pressure. Pulling the trigger too aggressively could result in safety risk.

- Do not transfer used hoses to a new canister set in order to prevent cross-contamination.

Packaging & Availability

- Packaging Type

- Packaging Data

Part 1 Canister: 48 lb (22 kg) per canister, 32 canisters per pallet. Packaged Weight: 53 lb (24 kg), 1696 lb (769 kg) per pallet NOTE: Package includes Canisters + Kit accessoriesPart 2 Canister: 44 lb (20 kg) per canister, 32 canisters per pallet. Packaged Weight: 44 lb (20 kg), 1408 lb (639 kg) per pallet NOTE: Package includes Canisters only

Storage & Handling

- Storage

- Store in original unopened containers between 60°F and 90°F until ready for use.

- Do not store in direct sunlight.

- Do not allow Quick Dual to freeze.

- Store canisters with valves facing up.

- Disposal

- During product disposal, wear recommended eye and skin protection.

- Maintain proper ventilation.

- Empty canisters completely of any remaining material.

- Add oil absorbent to waste components. Dispose of waste in an approved landfill.

- Turn empty canister upside down and open valve completely to relieve the canister of pressure.

- Once pressure is completely evacuated, locate and punch out the button on the shoulder of the canister using a non-ferrous punch.

- Empty canisters can be sent to a metal recycler or an approved landfill.

- Do not burn empty canisters. Dispose in accordance with local, federal, and state regulations.