Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

- Composition and Materials

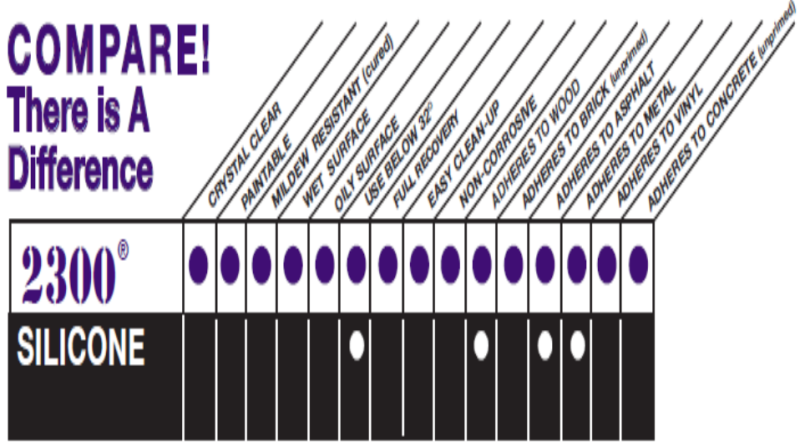

2300® Construction Tripolymer Sealant GC66853 is based on a proprietary formulation of polymers designed to provide optimum flexibility, adhesion, weather resistance, and durability. 2300® Construction Tripolymer Sealant GC66853 retains its flexibility due to the absence of plasticizers, which tend to migrate out causing hardening and reduced durability. Due to the mild solvent blend contained in the sealant, 2300® Construction Tripolymer Sealant GC66853 is not a flammable liquid according to NFPA liquid guidelines. It is weather and UV resistant. Its clear formulation is literally clear as glass from the moment of application

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Will not crack

- Asphalt shingle compatible

- Exceptional elongation and flexibility

- Excellent adhesion to many building surfaces, even when damp

- UV resistant

- Resealable, may be applied over itself

- Paintable

- Easily applied, non-stringing formulation

- Available in crystal clear, colors, and specially designed metal roof colors

- Cured sealant is mildew resistant

Applications & Uses

- Markets

- Applications

- Application Area

- Basic Uses

- Most non-traffic-bearing joints, including those where structural movement or stress is expected.

- Primerless application to brick, concrete, metal, glass, treated and untreated wood, asphaltic materials, and vinyl.

- Where UV resistant material is required.

- Where a paintable sealant is required

- As a trim sealant for a metal components

- Adheres to

Asphalt shingles, modified bitumen, coated steel (Kynar 500® based finishes), concrete, vinyl, steel, and other common building substrates

- Primer

Not required on most surfaces. If primerless adhesion to a particular surface substrate is a question, a test application is recommended. Contact our Technical Service Department for further information.

- Limitations

- Do not use on traffic-bearing surfaces

- Do not use on extruded polystyrene insulating sheathing (foam board, etc.)

- Do not use on acrylic skylight glazing surfaces

- Do not use in areas where food is stored or Processed

- For exterior use only due to odor emitted during cure

- Do not use for portable water applications

- Installations

Joint Design: For optimum results, joints should be a minimum of 4 times greater than anticipated movement. Minimum recommended joint size is ¼” x ¼”. Maximum joint size should be ½” x 3/8” in depth.

Surface Preparation: Priming is not required unless specified above. For best results, joints should be basically clean and surface dry, although dampness from dew will not interfere with adhesion. Do not use xylene or MEK to clean joints or to remove surface coatings unless surface can be allowed to dry before application of sealant. If the joint is wet with solvent, the sealant will not adhere properly. Use of a dry rag or brush to remove dust, dirt, or other contaminants is recommended. Contamination from curing agents and from releases should be avoided. Contact Geocel Products Group’s Technical Service Department or representative if such agents are involved.

Joint Backing: Joint depth should not exceed 3/8”. An open cell backer rod should be used to control joint depth. In shallow joints, a bond breaker tape should be installed to prevent three-point contact.

Application and Tooling: Apply with conventional caulking equipment, filling joint completely. When temperature is below 40˚ F (4.5˚ C), application will be easier if sealant is warmed. When temperature of surface to be sealed exceeds 140˚ F (60˚ C), do not apply sealant until surface cools. A soap solution or a solvent such as Xylene may be used as a lubricant for tooling. Follow manufacturer’s instruction for safe use. Do not allow tooling agents to contaminate open joints.

Painting: Sealant may be painted after 24 hours. If using a relatively inflexible paint, allow sealant to cure for four days before painting. 2300® Construction Tripolymer Sealant GC66853 may be coated with any latex and most oil-based paints. Some paints may crack when used on dynamic joints. See paint manufacturer’s specifications.

Cleaning: Remove 2300® Construction Tripolymer Sealant GC66853 from gun and tools before it cures. This may be done by scraping and use of solvents such as MEK (lacquer thinner), Xylol, Toluol, or chlorinated solvents. Cured materials may be removed by cutting with sharp tools. Observe manufacturer’s precautions when using toxic or flammable solvents.

- Maintenance

No maintenance should be required. If the sealant is damaged, either remove the bead and reseal with 2300® Construction Tripolymer Sealant GC66853 or apply additional 2300® Construction Tripolymer Sealant GC66853 over the damaged area.

Properties

- Color

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Elongation (Clear) | 1062.0 | % | — |

| Elongation (Colors) | 1180.0 | % | — |

| Tack Free | 45.0 | Minutes | — |

| Cure | 4.0 | Days | — |

Technical Details & Test Data

- Technical Services

Geocel Products Group representatives throughout the U.S.are available to provide technical assistance. Our in-housetechnical staff and laboratory facilities are equipped torespond to specific requests for further information.

Theoretical Yield Per 10.3 Fl. Oz. Cartridge

Joint Size Linear Feet 1/4" x 1/4" 24.8 ¼” x 3/8” 16.5 ¼” x ½” 12.4 ½” x 3/8” 8.7 - Comparability

Safety & Health

- Safety

Cautions: Contains aromatic hydrocarbons. Contents are combustible. Keep away from heat and open flame. Vapor harmful. Use only with adequate ventilation. To avoid overexposure, open windows and doors or use other means to ensure fresh air entry during application and drying. If you experience eye watering, headaches, or dizziness, increase fresh air, or wear respiratory protection (niosh approved) or leave the area. Avoid contact with eyes and skin. Wash hands after using. Keep container closed when not in use. Do not transfer contents to other containers for storage.

First aid: in case of eye contact, flush thoroughly with large amounts of water for 15 minutes and get medical attention. For skin contact, wash thoroughly with soap and water. In case of respiratory difficulty, provide fresh air and call physician. If swallowed, call poison control center, hospital emergency room, or physician immediately. Delayed effects from long term overexposure. Contains solvents which can cause permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents can be harmful or fatal.

Warning: this product contains chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Do not take internally. Keep out of reach of children.

Packaging & Availability

- Packaging Type

- Packaging

10.3 oz, Clear Plastic Cartridge

- Crystal Clear

10.3 oz, Plastic Cartridge

- Standard Colors

10.3 oz, Composite Cartridge

- Clear, White, Gray, Black, Brown, Bronze, Tan, and Cedar

Grade: Gun grade consistency

- Availability and Cost

2300® Construction Tripolymer Sealant GC66853 colors may not be sold in California. 2300® Construction Tripolymer Sealant GC66853 Crystal Clear may be sold innon-SCAQMD California counties only. Available fromvarious construction material and industrial distributors.

Storage & Handling

- Shelf Life

18 Months