Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Consistency

- Smooth Paste

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Benefits

- Fast reacting

- Non-Flammable

- Solvent-free

- Excellent moisture and alkali resistance

- Excellent plasticizer resistance

- When dry, does not promote growth of mold or mildew

- Low odor

- Easy to trowel

- Excellent indentation resistance

- Sets to a flexible, permanent bond

- FloorScore® Certified

- LEED Points Contribution and LEED Points

- MR Credit Regional Materials up to 2 points

- IEQ Credit 4.1 Low-Emitting

- Materials Adhesives and Sealants 1 point

Applications & Uses

- Markets

- Applications

- Application Area

- Coverage

- Surface Preparation

HELMIBOND 6503 can be used on porous and non-porous surfaces free of moisture. Surface to be covered must be dry, clean and smooth. Any foreign materials present such as paint, grease, oil, pen markings, adhesive residues, etc. that may prevent a proper bond or migrate to the surface causing a stain must be removed. Adhesive can be used on all grades of concrete on, above or below grade in the absence of moisture. Installation of a 0.010” or greater effective moisture retarder is recommended directly under all on and below grade concrete floors with its integrity insured. Concrete shall be prepared according to the recommendations outlined in ASTM F710 (Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring). Concrete floors shall be free from crazing, dusting, spalling and any curing or sealing compounds. Concrete floors shall be tested for moisture according to the latest revision of ASTM F2170 (Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes) and ASTM F1869 (Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride. Wood floors must be double construction with a 1" minimum thickness, structurally sound, securely fastened and free from deflection/spring. Top layer of wood shall be underlayment grade plywood. Cracks and uneven surfaces must be filled with an approved cement-based patching compound. It is the responsibility of the user to determine the porosity of the surface. To determine if a surface is porous, place a few droplets of water in various areas. If the subfloor is porous, the water will be absorbed within 2 – 3 minutes.

- Application

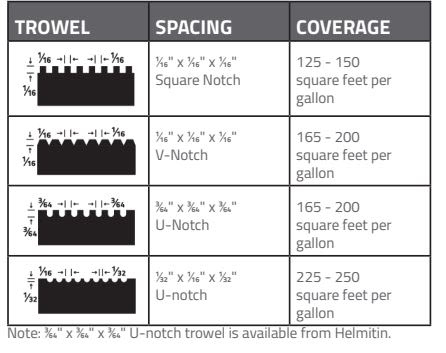

Porous Substrates Apply adhesive with a 1/16" x 1/16" x 1/16" square notch trowel for materials with a gage (thickness) of 0.080” or greater. Use a 1/16" x 1/16" x 1/16" V-notch trowel for materials with a gage (thickness) of 0.080” or less. When installing vinyl and/or rubber stair treads, apply adhesive with a 1/16" x 1/16" x 1/16" square notch trowel. Note: The 3/64" x 3/64" x 3/64" U-notch trowel can be used as an alternative to the 1/16" x 1/16" x 1/16" V-notch trowel. Contact Helmitin or more information. Spread adhesive evenly using the recommended trowel. Hold trowel at a 60° angle. Replace trowels with worn notches. Do not re-notch worn notches. For porous applications, the adhesive shall be allowed to remain open or flash-off for approximately 5 – 10 minutes before positioning flooring. The working time of the adhesive will be dependent upon substrate porosity, room temperature and humidity. Adhesive trowel notches must be pliable to receive flooring. Immediately roll flooring in both directions with a 100 lb threesection roller.

Non-Porous Substrates Apply adhesive with a 1/16" x 1/16" x 1/16" V-notch trowel for materials with a gage (thickness) of 0.080" or greater. Use 1/32" x 1/16" x 1/32" U-notch trowel for materials with a gage (thickness) of 0.080” or less. When installing vinyl and or rubber stair treads, apply adhesive with a 1/16" x 1/16" x 1/16" V-notch trowel. Note: The 3/64" x 3/64" x 3/64" U-notch trowel can be used as an alternative to the 1/16" x 1/16" x 1/16" V-Notch trowel.

Contact Helmitin for more information. Spread adhesive evenly using the recommended trowel. Hold trowel at a 60° angle. Replace trowels with worn notches. Do not re-notch worn notches. Non-porous installations require the adhesive to be dry to the touch, so that there is little or no transfer of adhesive to the finger. Once adhesive dries to the touch, it is ready to accept flooring material. Adhesive trowel notches must be pliable to receive flooring. When you run your finger across the trowel ridges, the ridges should be pliable with moderate finger pressure. From the time the adhesive dries to the touch, to the time it must be covered with flooring is approximately 45 – 75 minutes. If the adhesive remains uncovered longer than the recommended 45 – 75 minutes a loss in adhesion strength may result. The installer should not spread more adhesive than can be covered with flooring within the 45 – 75 minute time frame. Note: as long as flooring is positioned while trowel notches are pliable do not look for peel strength or transfer to back of flooring. Immediately roll flooring in both directions with a 100 lb three-section roller.

Post Installation Prevent all traffic for a minimum of 24 hours. Restrict heavy traffic and rolling loads for a minimum of 72 hours after installation. Do not wash or begin maintenance procedures on the floor for a minimum of 5 days after installation to allow the adhesive to properly cure.

- Clean-up

Remove wet adhesive immediately with a clean cloth dampened with mineral spirits, isopropanol or acetone. Cured adhesive is very difficult to remove. Do not apply solvents directly to flooring. Use caution when handling flammable solvents.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| VOC | max. 1 | grams/liter | SCAQMD Rule1168 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Testing Methods

- Freeze-thaw stability (ASTM D7149)

- Shelf Life (ASTM D1337)

- Adhesive Shear Strength (ASTM D6004)

- 90° Peel Resistance (ASTM D6862)

- Plasticizer Resistance (ASTM D7888)

- Heat Aged Expansion/Contraction

- Technical Details

LEED Points Contribution LEED Points MR Credit Regional Materials Up to 2 points IEQ Credit 4.1 Low-Emitting Materials Adhesives and Sealants 1 point This adhesive formulation has received a C2C Certified Material Health Certificate™ at the Gold level.

- Acclimation

The area to receive flooring shall be fully enclosed, weather tight, with an installed operating HVAC system. The installation area, flooring materials and adhesive must be acclimated at a temperature between 65°– 85°F for 48 hours prior to, during and after installation. The relative humidity of the installation area shall be maintained between 35 – 55% per ASTM F710 (Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring)

Safety & Health

- General Warranty & Precautions

Helmitin warranties its private label adhesive formulations to be free of all manufacturing defects. The warranty period shall be in place for one (1) year from the date of installation and will also be guided by the date of manufacture to insure the integrity of the formulation and that proper storage and shipment of same has taken place. Please contact Helmitin for detailed warranty information. Carefully read and follow all precautions and warnings. Keep out of reach of children

- General Warranty & Precautions

Helmitin warranties its private label adhesive formulations to be free of all manufacturing defects. The warranty period shall be in place for one (1) year from the date of installation and will also be guided by the date of manufacture to insure the integrity of the formulation and that proper storage and shipment of same has taken place. Please contact Helmitin for detailed warranty information. Carefully read and follow all precautions and warnings. Keep out of reach of children

Packaging & Availability

- Packaging Type

- packaging

HELMIBOND 6503 is available in 1-gallon and 4-gallon pails.

Storage & Handling

- Shelf Life

18 months in unopened properly stored containers

- Freeze-thaw

5 cycles at 0°F. If adhesive has frozen, thaw under no lroom temnerature