Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Benefits

- Fast reacting

- Non-Flammable

- Solvent-free

- Excellent moisture and alkali resistance

- Excellent plasticizer resistance

- When dry, does not promote growth of mold or mildew

- Low odor

- Easy to trowel

- Excellent indentation resistance

- Sets to a flexible, permanent bond

- FloorScore® Certified

- LEED Points Contribution and LEED Points

- MR Credit Regional Materials up to 2 points

- IEQ Credit 4.1 Low-Emitting

- Materials Adhesives and Sealants 1 point

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Coverage

- Application

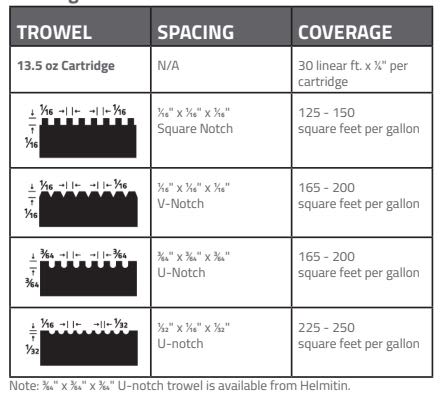

Stair Tread Application Cartridge adhesive automatically mixes when pumped through static mixer. The use of the static mixer supplied with the cartridge is required to insure proper mixing of the Part A & B components. Cut the tip of the static mixer to desired width. Apply a sufficient amount of epoxy nose caulking into the inside nose area of the stair tread to completely fill the void between the stair nosing and the nosing of the step. Position stair tread, making sure that the nosing of the stair tread is positioned tightly against the step nosing. When installing treads from the bottom working up, do not kneel or step of the nosing of the tread as this can cause displacement of the adhesive. Roll the tread and riser areas with a hand roller. Do not roll the nosing of the stair tread as this can cause displacement of the adhesive. Allow minimum 24-hours cure time before allowing foot traffic. Lower temperatures will require longer waiting periods. Flooring Application 1. HELMICOL 3031 can be used on porous and non-porous surfaces free of moisture. Surface to be covered must be dry, clean and smooth. Any foreign materials present such as paint, grease, oil, pen markings, adhesive residues, etc. that may prevent a proper bond or migrate to the surface causing a stain must be removed. Adhesive can be used on all grades of concrete on, above or below grade in the absence of moisture. Installation of a 10-mil (0.010”) or greater effective moisture retarder is recommended directly under all on and below grade concrete floors with its integrity insured. Concrete shall be prepared according to the recommendations outlined in ASTM F710 (Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring). Concrete floors shall be free from crazing, dusting, spalling and any curing or sealing compounds. Concrete floors shall be tested for moisture according to the latest revision of ASTM F2170 (Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes) and ASTM F1869 (Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride. Wood floors must be double construction with a 1" minimum thickness, structurally sound, securely fastened and free from deflection/spring. Top layer of wood shall be underlayment grade plywood. Cracks and uneven surfaces must be filled with an approved cement-based patching compound. 2. Pour the entire contents of the Part B container into the Part A container. Using a low speed mixer, thoroughly mix the contents until a smooth, even colored consistency is achieved. Immediately pour the entire contents onto the substrate. Do not allow mixed adhesive to set in container. Spread adhesive evenly using the recommended trowel. Refer to above chart for trowel notch recommendations. Hold trowel at a 60° angle. Replace trowels with worn notches. Do not re-notch worn notches. 3. Note: The 3/64" x 3/64" x 3/64" U-notch trowel can be used as an alternative to the 1/16" x 1/16" x 1/16" V-notch trowel. Contact Helmitin for more information. 4. Once applied, the working time of the adhesive is 50 - 60 minutes (higher room temperatures will result in shorter open times). To insure transfer of adhesive to back of flooring, flooring material must be positioned while adhesive is wet. Allowing a 10-minute open time before positioning flooring will help reduce tile shifting and adhesive bleed through at tile joints. Kneeling boards are recommended when working on tile. When installing sheet flooring, the use of a push board will help remove excess air under the flooring. Immediately roll flooring in both directions with a 100 lb three-section roller. 5. Prevent all traffic for a minimum of 8-hours. Prevent heavy traffic and rolling loads for a minimum of 24 - 48 hours after installation. Do not wash or begin maintenance procedures on the floor for a minimum of 5-days after installation. Lower temperatures will result in longer cure times.

- Clean-up

Remove wet adhesive immediately with a clean cloth dampened with mineral spirits, isopropanol or acetone. Cured adhesive is very difficult to remove. Do not apply solvents directly to flooring. Use caution when handling flammable solvents.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Working Time ( 75°F) | 45-50 | minutes | — |

| VOC | max. 12 | grams/liter | SCAQMD Rule1168 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Testing Methods

- Freeze-thaw stability (ASTM D7149)

- Shelf Life (ASTM D1337)

- Adhesive Shear Strength (ASTM D6004)

- 90° Peel Resistance (ASTM D6862)

- Plasticizer Resistance (ASTM D7888)

- Caster Chair (ISO 4918)

- Heat Aged Expansion/Contraction

- Technical Details

LEED Points Contribution LEED Points MR Credit Regional Materials Up to 2 points IEQ Credit 4.1 Low-Emitting Materials Adhesives and Sealants 1 point

Safety & Health

- General Warranty & Precautions

Helmitin warranties its private label adhesive formulations to be free of all manufacturing defects. The warranty period shall be in place for one (1) year from the date of installation and will also be guided by the date of manufacture to insure the integrity of the formulation and that proper storage and shipment of same has taken place. Please contact Helmitin for detailed warranty information. Carefully read and follow all precautions and warnings. Keep out of reach of children

- General Warranty & Precautions

Helmitin warranties its private label adhesive formulations to be free of all manufacturing defects. The warranty period shall be in place for one (1) year from the date of installation and will also be guided by the date of manufacture to insure the integrity of the formulation and that proper storage and shipment of same has taken place. Please contact Helmitin for detailed warranty information. Carefully read and follow all precautions and warnings. Keep out of reach of children

Packaging & Availability

- Packaging Type

- packaging

HELMICOL 3031 is available in 13.5-ounce cartridges, 12 cartridges per carton and 1-gallon units

Storage & Handling

- Shelf Life

18 months in unopened properly stored containers

- Freeze-thaw

Freeze-thaw stable. Allow adhesive to aclimate to room temperature