Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Benefits

- Excellent Adhesion to Metal.

- V.O.C. Compliant/Environmentally Friendly

- Excellent Gloss Retention

- Resistant to early Water Spotting and Wrinkling

- Non Flammable/Low Odor

- Excellent resistance to U.V. Exposure

- Water Clean-Up

Applications & Uses

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Recommended Uses

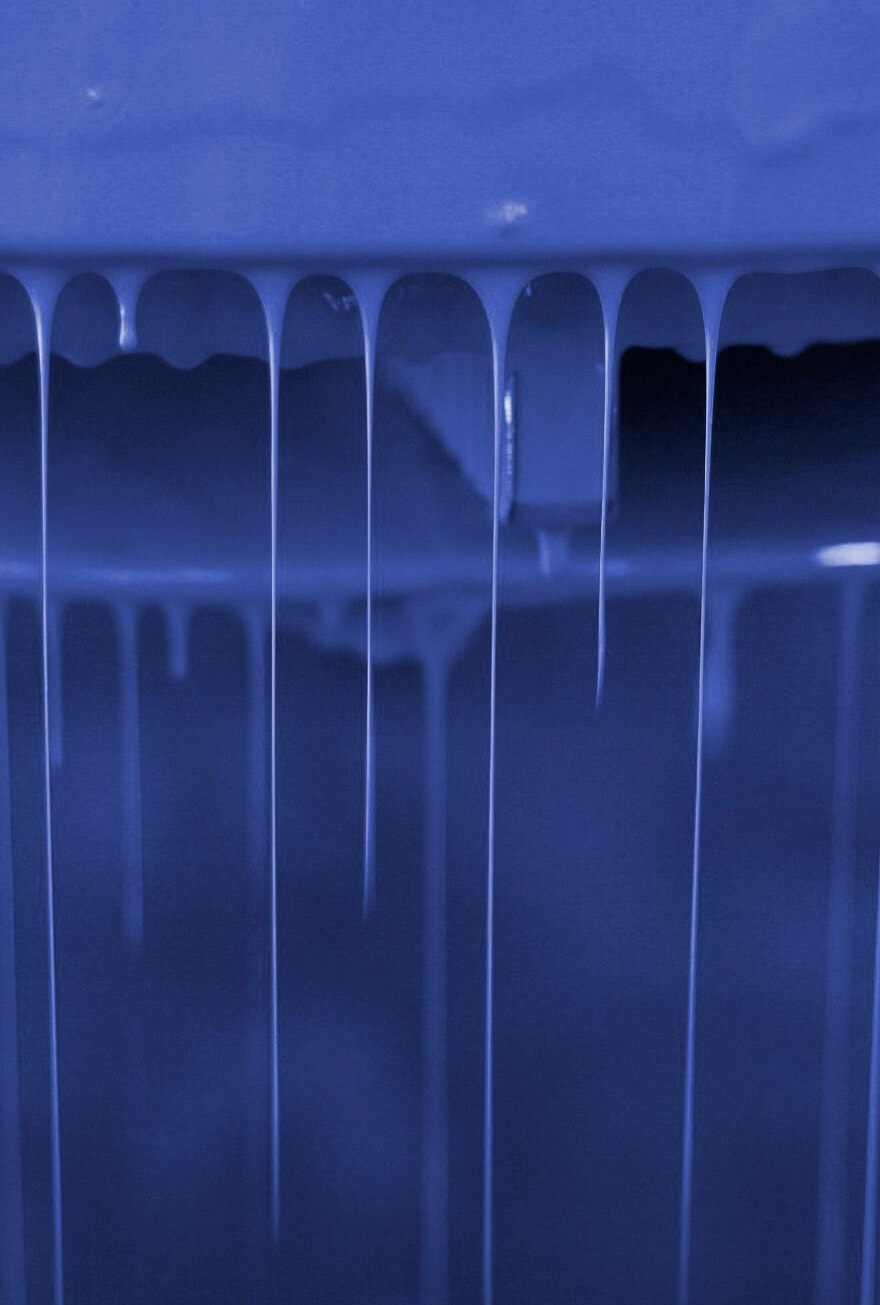

Applications include O.E.M. heavy-duty construction equipment, storage and disposal containers, automotive components, farm machinery, feed and grain bins, livestock equipment, tanks, trailers and general industrial finishing. 40 Series can also be used on exterior substrates where most oil base enamels lose their gloss and become chalky because of weathering and UV exposure.

- Surface Preparation

All substrates must be cleaned free of dust, dirt, oil, grease, soap residue, wax, flaking paint, form oils or parting compounds and any other contaminants. Solvent wipe and/or detergent clean with TZ Paint Prep (Waterbased Solvent Degreaser). Sandblast or wire brush rusted surfaces and prime with 49 series primer. For optimum adhesion and corrosion resistance, metal should be iron phosphate treated.

- Application

- Mixing: Stir each container thoroughly before using and occasionally while applying. No thinning usually required. If necessary, thin with up to one pint of water to each gallon of paint. Application: Apply with air, airless, air assisted airless, turbo or HVLP spray systems.. For airless or air assisted airless application, use a 0.011-0.015” tip at 1800 psi. For air spray, use 50 psi air pressure and 8 psi fluid pressure with conventional air cap, tip and needle. Max of 15% water may be applied for dip or flow coat applications.

- Coverage: One gallon will cover 350 square feet per coat on smooth surfaces. Coverage figure does not include spray loss, loss due to surface porosity, surface irregularities, nor material loss when mixing.

- Cleanup: Clean equipment promptly with warm water. Give spray equipment a final flush with mineral spirits to help prevent corrosion. Dispose of used paint and waste in accordance with local, state and federal regulations.

- Application Precautions & Limitations: Apply when surface, air and product are above 50°F and at least 5°F above the dew point. Product may be force cured with conventional or IR heat. Product cure can be accelerated with force temperatures from 150-250°F within a time element of 2-20 minutes. Increases in heated air flow can significantly reduce the amount of oven time.

Properties

- Color

Safety & Health

- Environmental & Safety Statement

This product is not formulated with any lead, chrome or mercury containing ingredients. Do not take internally. Keep out of the reach of children. Use with adequate ventilation.